UV Laser Coders for Pouch Packaging Machines

Pouch packaging machines have grown to be a crucial manufacturing component as they effectively fill and seal goods in flexible packaging. When combined with leading UV laser coding technology, these devices offer precise, durable, and eco-friendly product marking.

We’re here to provide you with more details.

Reach out today!

What Is a Pouch Packaging Machine/Bag Filling Machine?

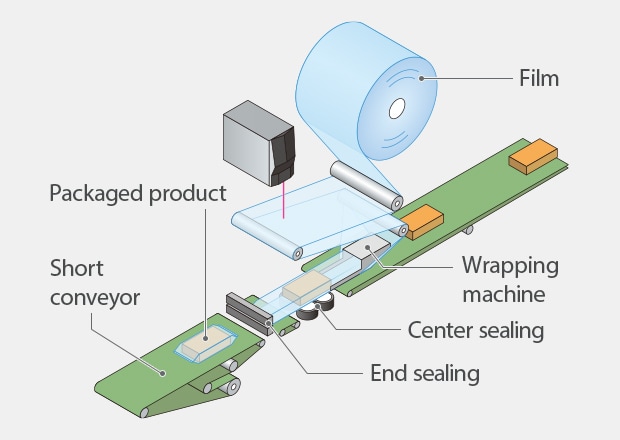

A pouch packaging machine, also known as a bag filling machine, is a specialized device used to fill and seal preformed pouches or bags with products. The food and beverage, pharmaceutical, and cosmetics industries are just a few that use pouch filling and packing machines.

More specifically, the machines fill and seal pouches from a roll of material. The machine opens or forms the pouch, fills it with the product, and seals it securely using heat or pressure. Unlike rotary baggers, which rotate to perform these tasks, pouch machines operate as linear baggers, completing the process in a straightforward, linear motion. Optional features like printing or labeling are common, and finished pouches are discharged or cut and collected for further handling.

Advantages of UV Laser Coders for Pouch Packaging Machines

Efficiency

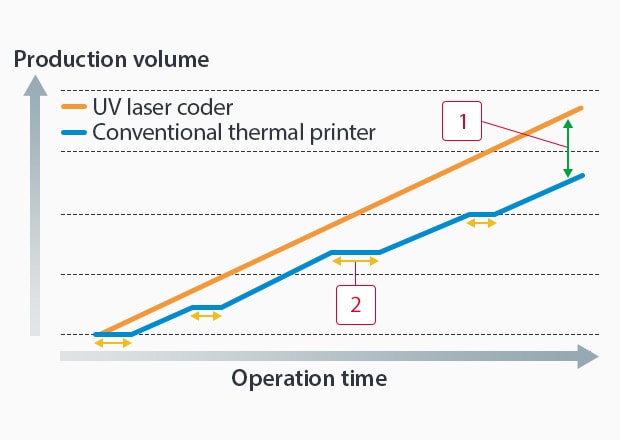

UV laser coders eliminate the need for consumables, reducing downtime for maintenance and replacements. This allows a pouch packaging machine to elevate operations with higher throughput and minimal interruptions.

No line stoppages

No periodic parts replacement required

No consumables

No periodic maintenance/inspection required

Flexibility

Capable of marking various pouch materials, including plastics and foils, UV laser coders ensure high-quality, permanent markings regardless of packaging type or size.

Cost-Effectiveness

By removing the need for ink, ribbons, and frequent maintenance, UV laser coders lower operational costs while delivering high-speed marking on bag-filling machines.

-

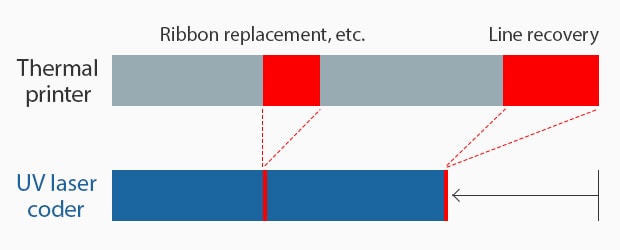

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Product Protection

Non-contact laser coding ensures markings without compromising the integrity of the pouch, maintaining airtight seals that keep products fresh and protected.

Sustainability

UV laser coding is an eco-friendly solution that eliminates consumable waste, supporting sustainable packaging initiatives with clean, chemical-free marking.

Curious about our pricing?

Click here to find out more.

Versatile Applications of UV Laser Coding for Pouch-Filling and Bagging Machines

UV laser coding enhances pouch-filling and bagging machines by providing the versatility manufacturers require. Applications from various industries include the following:

Food and Beverages

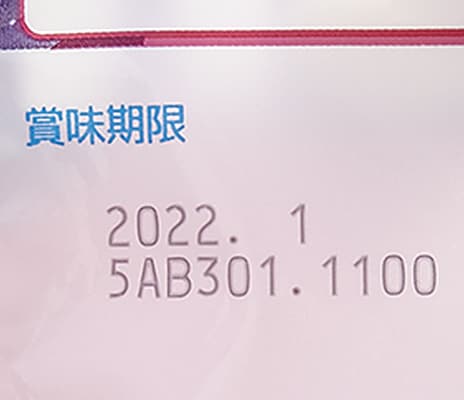

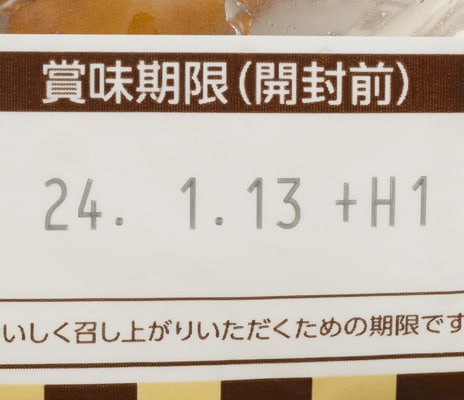

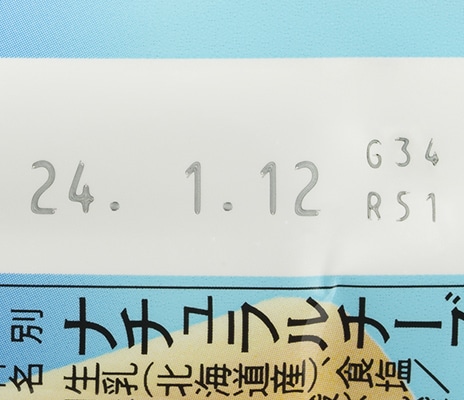

UV laser coders create precise date codes, batch numbers, and branding on snack packaging, powdered drink pouches, sauce packets, and coffee bags without affecting product quality.

Pharmaceuticals

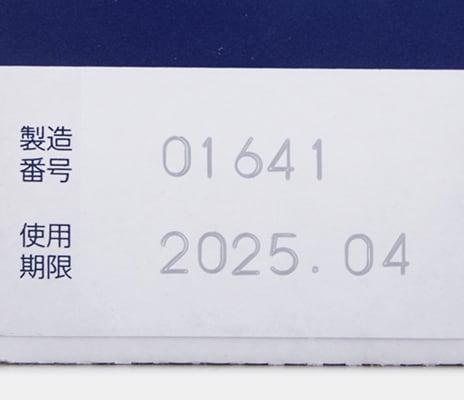

Essential for regulatory compliance, UV laser coding offers clear, non-smudging, permanent markings on tablet pouches, powder sachets, and liquid medication packaging.

Cosmetics

From single-use sachets to lotion tubes, UV laser coders provide sharp, durable markings on flexible packaging, improving branding and product authenticity.

Industrial Products

Ideal for marking chemicals, fertilizers, and cleaning agents, UV laser coding withstands harsh environments while maintaining legibility on various pouch materials.

Discover more about this product.

Click here to book your demo.

UV Laser Coder vs TTO for Premade Pouch-Filling Machines

When it comes to marking and coding on pouches, UV laser coders and thermal transfer overprinting (TTO) are common options. Here’s how they compare:

Durability & Precision

UV laser coding creates precise and permanent marks that resist smudging, fading, and external factors like heat and friction, unlike TTO prints that can wear off.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Operating energy for packaging line equipment (packaging machine, compressor, air conditioner, lighting, etc.) can be significantly reduced.

Eco-Friendliness

UV lasers operate without consumables like ink ribbons, eliminating waste and reducing environmental impact.

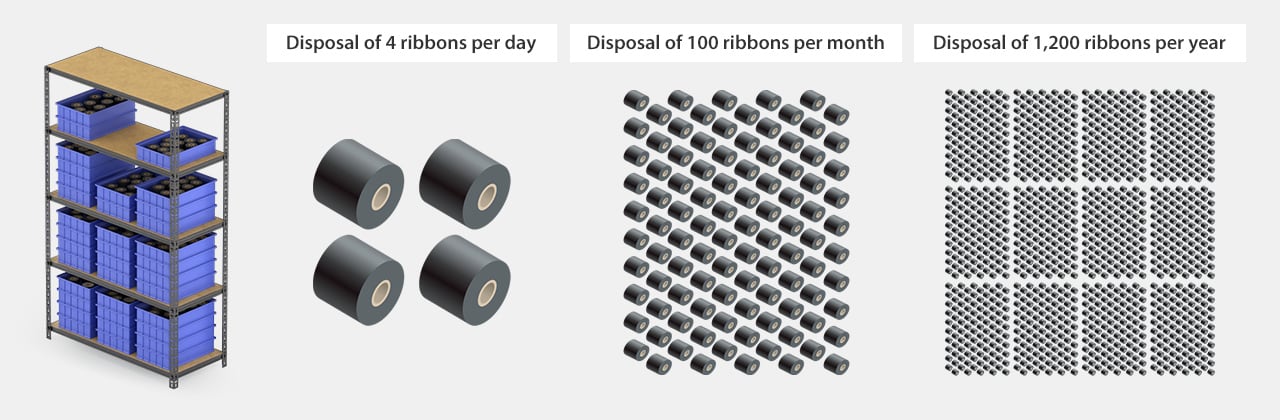

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Cost Efficiency

With no consumables, UV laser coders lower operational costs.

Maintenance

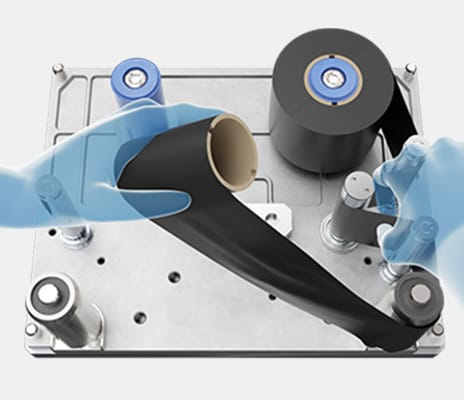

UV lasers require minimal maintenance compared to TTO printers, which need frequent ribbon replacements and cleaning.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Coding for Pouch Packaging Machines

How Does the FP-1000 Series UV Laser Coder Improve the Efficiency of Pouch Packaging Machines?

Through the removal of consumables, decreased downtime, and the provision of durable markings, the FP-1000 Series improves efficiency.

What Maintenance Requirements Are There for UV Laser Coders on Pouch-Filling and Packing Machines?

UV laser coders are low-maintenance devices. To guarantee ideal performance, the lens and cooling fans must be cleaned occasionally depending on environment. Unlike TTO printers, there’s no need for frequent consumable replacements.

How Does the FP-1000 Series UV Laser Coder Reduce Downtime and Improve Efficiency on Pouch Packaging Machines?

The FP-1000 Series laser coder eliminates downtime associated with ribbon changes and head cleaning seen in TTO systems. Its sturdy design guarantees uninterrupted operation, increasing production throughput and Overall Equipment Effectiveness (OEE).

How Does UV Laser Coding Ensure Product Traceability and Quality on Premade Pouch-Filling Machines?

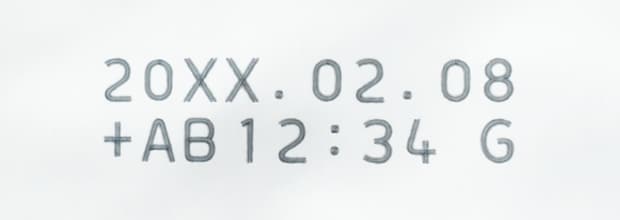

UV laser coders produce permanent, high-resolution markings that include barcodes, batch numbers, and expiration dates. Markings remain intact during transportation and handling, ensuring traceability and compliance with industry standards.

Does the FP-1000 Series UV Laser Coder Require Special Training to Operate Pouch-Filling and Packing Machines?

The FP-1000 Series is simple to integrate and use thanks to its intuitive controls and user-friendly software. Its operation and maintenance can be managed with basic training, negating the need for specialized knowledge.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)