Vision Examples in the Food and Pharmaceutical Industries

Machine vision for protecting food safety and contributing to inspection efficiency

We enjoy a rich and varied diet through economic development. This has made production and distribution increasingly complicated, which poses many questions such as: "Where was this product produced?" or "Are there any problems with residual pesticides or radioactive materials?" Under these circumstances, food safety has once again become a topic of interest. Japanese government agencies including the Ministry of Health, Labour and Welfare; the Ministry of Agriculture, Forestry and Fisheries; and the Consumer Affairs Agency have been encouraging the reinforcement of inspection standards and implementation of traceability.

Conventional inspections of expiration dates, mixing of foreign matter, package failures and other problems had to rely on the human eyes and experience, which was both expensive and time consuming. The human eyes have limitations and it is difficult to visually judge some targets such as medicine pills. In order to reduce the time and labor for improving productivity and to deliver safer and more secure food, an increasing number of companies have introduced image processing in their inspection processes in recent years. The following are examples of machine vision introduced in the food and pharmaceutical industries.

Presence/absence inspection

Presence inspection for seasoning packets

Check the presence or absence of package contents such as packets of ingredients in instant noodles with machine vision.

Key inspection points

Using machine vision, check the presence or absence of packets of ingredients and soup in instant noodles. A single controller can control multiple cameras. This improves operability and enables use for parallel production lines.

Recognition result with machine vision

Bottle count in cases

Using machine vision, count PET bottles in a cardboard box.

Key inspection points

Using a 21 megapixel camera enables high-accuracy inspection even over a wide field of view. In addition to counting bottles, a single camera enables other inspection such as the inspection of caps for different types by checking minute differences in characters or colors.

Recognition result with a 21 megapixel machine vision

Juice box straw inspection

Using machine vision, check the presence of straws on juice cartons.

Key inspection points

Checking straw attachment on juice cartons had been unstable due to the non-flat background and variations in the straw position. The LumiTrax function allows stable inspection without being affected by background or position variations.

Recognition result with machine vision and LumiTrax

Defect inspection

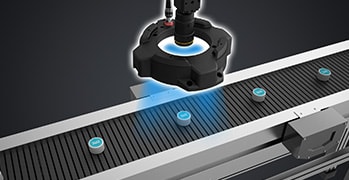

Appearance inspection of plastic caps

This is a quality inspection of plastic caps on a conveyor.

Key inspection points

When performing an inspection for flaws on packaging, the colors and logos can be confused with defects. By using colored lighting, the defect can simply be extracted from the background.

Recognition result in normal illumination mode

(after color extraction)

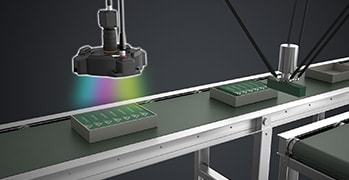

Inspection for foreign particles in jelly after filling

Inspection for foreign contamination during an in-line dispensing process.

Key inspection points

When inspecting for dirt, hair, and other unacceptable contamination in a packaging process, flexible lighting is needed to detect the NG parts. Using Multi-Spectrum lighting, slight color variations can be extracted to detect only the defective parts.

Recognition result in multi-spectrum mode

(after color extraction)

Appearance inspection during packing process

This is an appearance inspection during the packing process.

Key inspection points

Under conventional lighting conditions, differentiating the color of the package or markings from defects or dirt can be difficult. If Multi-Spectrum mode is used, even minor defects or dirt can be reliably extracted for stable and reliable inspections.

Recognition result in multi-spectrum mode

(after color extraction)

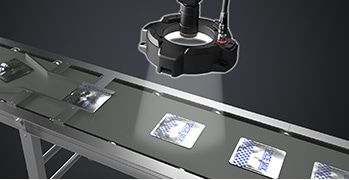

Appearance inspection of blister packaging

This is an inspection of tablets inside blister packaging.

Key inspection points

Conventionally, the contrast between the color of the tablet and the film packaging is so small that reliable inspection is not possible. It is possible to accurately inspect only for flaws in the tablets by illumination with IR lighting.

Recognition result in normal illumination mode

(post-processed image)

Shrink wrap inspection

Use machine vision for appearance inspection of PET bottle labels to find tears or flaws.

Key inspection points

Inspect PET bottles for torn shrink labels. The high-speed processing can keep up with the fast-moving lines used in the beverage industry.

Recognition result with machine vision

Food tray inspection

Using machine vision, inspect food containers for stains or flaws.

Key inspection points

Inspect food containers for defects such as stains or wrinkles. High-pixel cameras are also capable of high-speed processing. They can be used even when the inspection requirements will grow or the line speed will increase in the future.

Recognition result with machine vision

Pasta contamination and hole inspections

Use machine vision for appearance inspection of noodle dough for stains or holes.

Key inspection points

Inspection of noodle dough for stains or holes has to check a wide range. Conventional area cameras could not offer stable judgment because the lighting conditions were not even over the entire range KEYENCE's line scan cameras can achieve even lighting conditions to allow stable inspection.

Recognition result with a line scan camera

Can side appearance inspection

Using machine vision, inspect beverage cans for dents or flaws.

Key inspection points

Appearance inspection of cans to find dents or other defects on the sides was difficult because the judgment was affected by printing. Line scan cameras can ignore the printing and extract dents and flaws only.

Recognition result with a line scan camera

Dimension inspection

Needle edge inspection

Using machine vision, inspect the dimensions of syringe needle bevels.

Key inspection points

The bevel of a syringe needle is cut slantwise twice to lessen pain during use. Conventional machine vision could not differentiate the surfaces. Using specific lighting conditions has enabled accurate measurement and management of the dimensions of the bevels.

Recognition result with machine vision

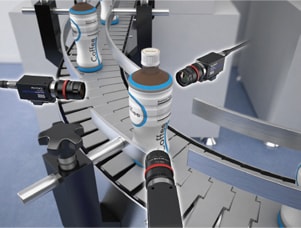

Label alignment inspection

Using machine vision, inspect the misalignment of container labels.

Key inspection points

Inspect the labels wrapped around containers for misalignment. In addition to misalignment, peeling labels and other appearance defects can be inspected simultaneously.

Recognition result with machine vision

Packaging seal inspection

Using machine vision, inspect the sealing width of packets.

Key inspection points

The inspection of packet sealing width was unstable due to the influence of patterns, uneven surfaces and glare. The LumiTrax function enables inspection based on shape only, by using the information of the uneven surface of the sealed section.

Recognition result with machine vision and LumiTrax

Positioning/alignment

Pattern inspection for can orientation

Using machine vision, detect patterns on cans and recognize the orientation.

Key inspection points

Before cans are packed, detect the patterns to align the orientation. Outputting the position information of a mark to the facility for the correction to rotate the product saves labor for packing.

Pattern alignment with machine vision

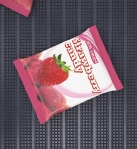

Robot guidance for candy packaging

Use machine vision for positioning for a confectionery boxing robot.

Key inspection points

Boxing of confectionery packs was a typical process that was done manually; however, it has been increasingly automated through the introduction of image processing and robots.

Positioning with machine vision

Verification inspection

Print inspection of medical cartons

This is a print inspection of medical cartons.

Key inspection points

In conventional inspections, similar colors between the background and the markings can cause difficulties. By using LumiTrax™ mode, it is possible to accurately extract only the uneven surfaces of text and markings, resulting in stable and reliable inspections.

Recognition result in LumiTrax™ mode

(shape image)

Print inspection of aluminum film

This is an appearance inspection of aluminum packaging film.

Key inspection points

In conventional inspections, the gloss and background color of the target can cause difficulties in text or marking identification. By using LumiTrax™ mode, it is possible to accurately extract only the uneven surfaces of text and markings, resulting in stable and reliable inspections.

Recognition result in LumiTrax™ mode

(post-processed image)

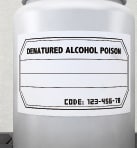

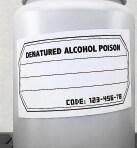

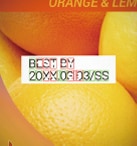

“Best by date” printing inspection

Using machine vision, check best-before dates marked on food or medicine products.

Key inspection points

The system checks for defective marking such as incorrect marking or illegible characters. Storing the inspection data with images for long periods is an effective provision in case of trouble.

Recognition result with machine vision

Date, lot code, and barcode inspections

Using machine vision, inspect characters and barcodes printed on medicine packages.

Key inspection points

The need for traceability is increasing in the pharmaceutical industry. Image processing allows a single inspection system to conduct various inspections, checking characters, barcodes labels, and more.

Recognition result with machine vision

3D Machine Vision Inspections

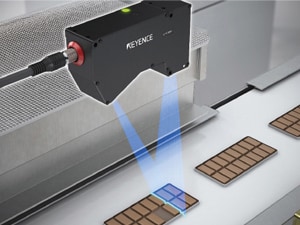

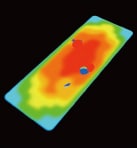

Chocolate bar inspections

Using a 3D measurement system, count chocolate pieces and check for missing pieces.

Key inspection points

Using the LJ-V7000 Series 3D measurement system enables not only counting targets but also checking voids or foreign particles on the target surfaces as well.

Recognition with 3D images

Dent

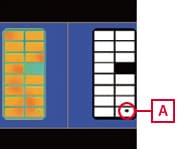

Tablet blister pack inspection

Using a 3D measurement system, inspect the appearance of blister packs.

Key inspection points

It is very difficult to perform stable inspections for tears in blister packaging. By using a 3D machine vision, it is possible to detect these defects without being affected by surface glossiness and curvature.

Recognition with 3D images

![The Latest Machine Vision Inspections [Food and Medical Industries]](/img/asset/AS_72814_L.jpg)

![A Technical History of Image Processing Vol.1 [Camera]](/img/asset/AS_46814_L.jpg)

![The Latest Image Processing Applications [Transportation Industry]](/img/asset/AS_71759_L.jpg)