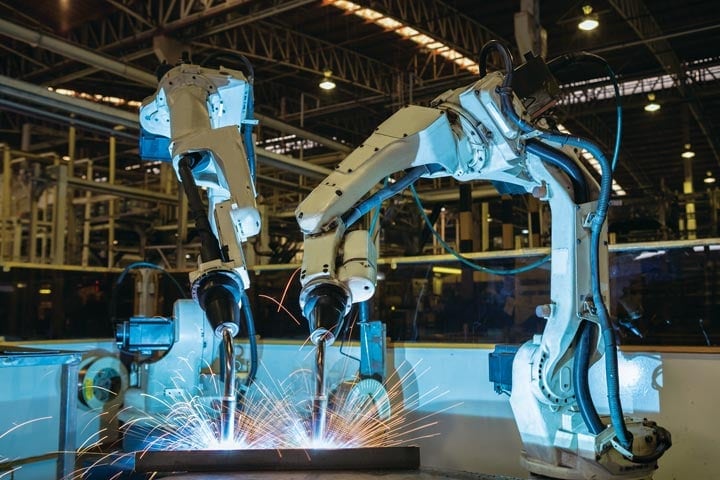

Welding automation

Along with the proliferation and falling costs of FA (factory automation) equipment resulting from advances in digital technology, welding work has also evolved from manual welding, through semi-automatic welding to fully automatic welding. Meanwhile, robot welding has also been expanding in the automotive and other industries, and has become indispensable for streamlining welding processes.

The proliferation of robots is further encouraged by the latest instruments such as sensors, displacement meters, controllers and PLCs that enable high-speed, high-accuracy detection and feedback control. The introduction of robots for welding processes is increasing steadily.

Robot welding is certainly the driving force behind the advancement of FA. The typical advantages of robot welding are:

- Making up for shortfalls in experienced welders

- Equalizing the quality of welding work

- Ensuring productivity

- Recording work conditions to provide traceability for quality assurance

On the other hand, operating welding robots properly requires not only the welding skills but also knowledge of control sequences, mechanism design, and safety control. There is an imperative need to develop the relevant human resources.