Handheld Probe Coordinate Measuring Machine

XM series

Easy-to-Use Handheld Probe Coordinate Measuring Machine XM series

[Anyone] Easy-to-Use Free-Angle Probe Easy-to-Use Free-Angle Probe Designed for Improved Usability and Accuracy

Touch Sensor

The built-in touch sensor is specially designed to activate when a certain amount of contact pressure is applied. This prevents variations due to contact pressure.

Wireless

Wireless LAN connectivity makes it possible to use the probe in any setting without fussing with cables.

Adjustable Grip

The handheld grip can be rotated 90 degrees to either side, allowing for a more comfortable hold while the angle of the markers can be adjusted to face the camera.

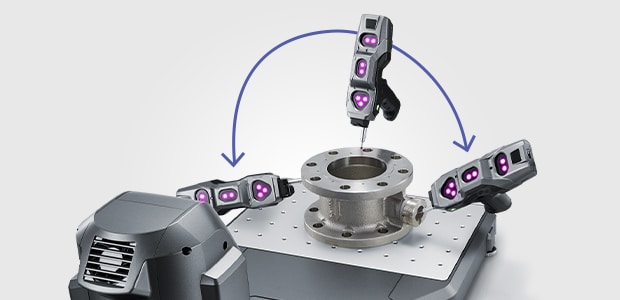

Free-Angle Probe for Intuitive Handling

As long as the probe is within the camera’s field of view, measurement locations can be approached from any angle. The probe can be used to measure the top surface of parts, horizontal or angled holes, and the rear with no part adjustment.

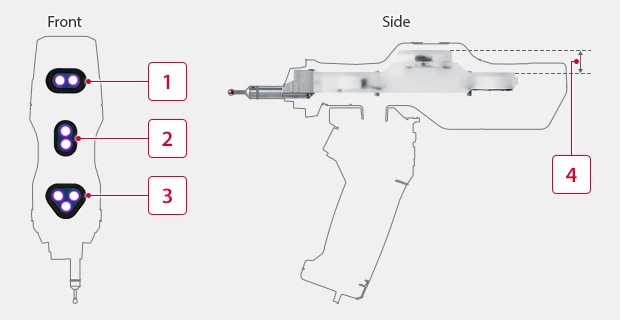

Probe Marker Position

Placing markers horizontally, vertically, in a triangle, and at different heights allows for stable measurement accuracy.

-

1Horizontal

-

2Vertical

-

3Triangle

-

4Different height

OLED Display

Wide-variety of Stylus Options

* Compatible with commercially available products.

Operation Buttons

Probe Detection Status Confirmation LED

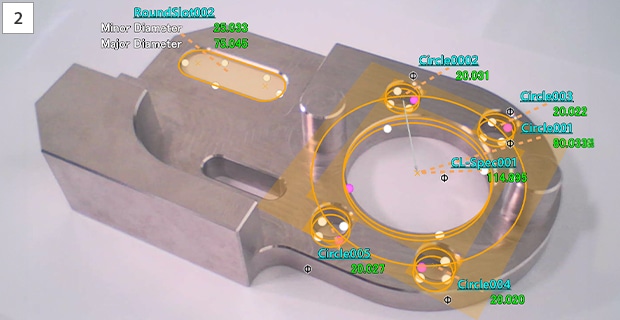

[Anyone] Visual Measurement Overlay Image-Based Measurement Results for Easy Visualization

-

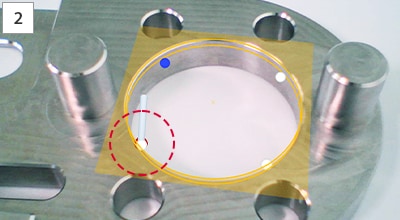

1Small probe camera

The camera captures images of the target. As measurement is performed...

...the measurement results are displayed in real-time on the captured image.

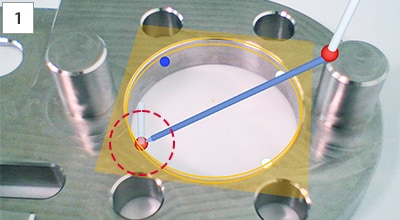

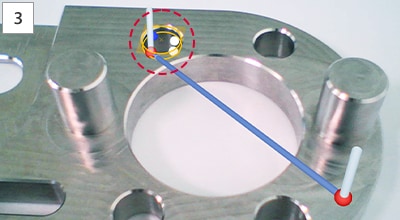

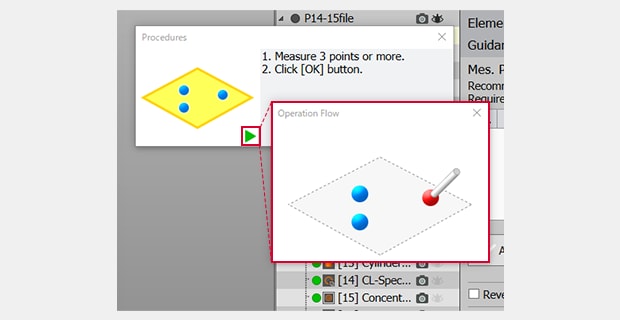

On-Screen Visual Guidance for Repeated Measurements

Anyone can measure a feature the same way it was originally measured simply by placing the probe against the location on the part displayed on the screen. The XM-5000 reduces subjectivity by automatically detecting if measurements were taken correctly.

Measurement point instructions are displayed.

Follow the instructions to perform measurement.

Follow the next instruction to continue measurement.

Continue to measure all parts without any expertise required.

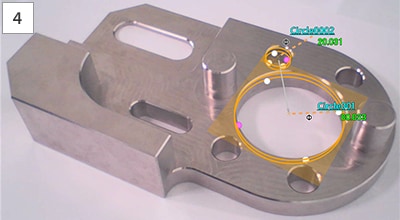

The measurement results will be displayed in a list alongside the judgment results.

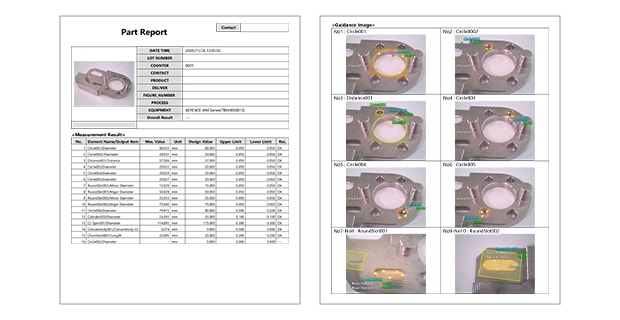

Automatic Creation of Inspection Reports with Images for Easy Comprehension

The XM-5000 comes standard with a function for automatically creating inspection reports and work procedures that include camera images. Measurement points and items are laid out automatically, resulting in significant reductions in inspection report and operating instruction preparation time.

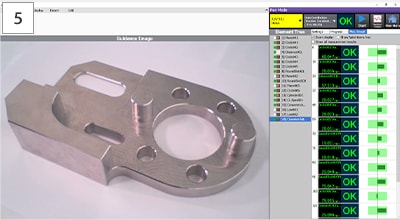

[Anyone] Simple Interface Easy-to-Use and Understand, Even for First-Time Users

Coordinate measuring machine interfaces are often a mess of complex and unfamiliar commands.

The XM-5000, however, uses images, icons, and other tools to ensure intuitive operation for any user.

-

1Measurement results display

-

2Sortable elements tree:

Drag measured elements up or down to change the order.

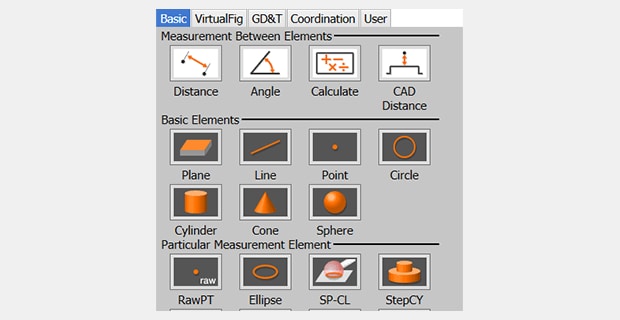

Easy-to-Understand Basic Measurement Menu

Frequently used basic measurement elements such as planes, lines, points, circles, cylinders, cones, and spheres are consolidated into a single tab. Each tool also comes with video instructions.

Clicking the button on the screen will bring up a window showing video instructions.

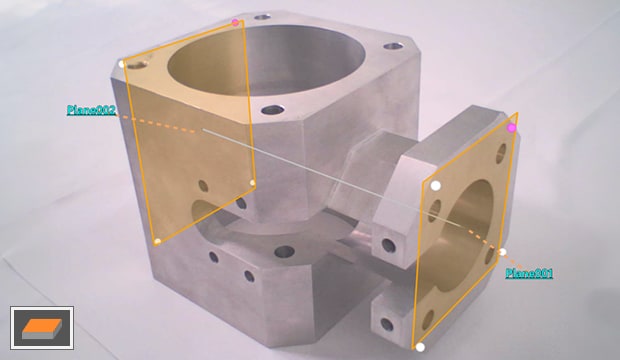

Simple Interface for Intuitive Operation

Measurement can be performed without any complicated programming or selecting multiple commands with just three simple steps.

The intuitive operation makes it possible even for those unfamiliar with measurement to obtain measurement results easily.

Select the Elements to Measure

Click Plane from the Basic Elements in the measurement menu.

Touch the Probe to the Measurement Location

Simply the Items to Measure

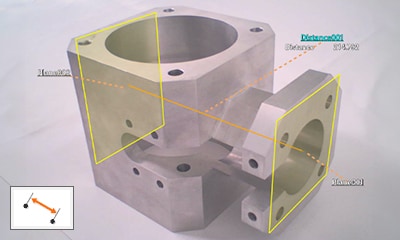

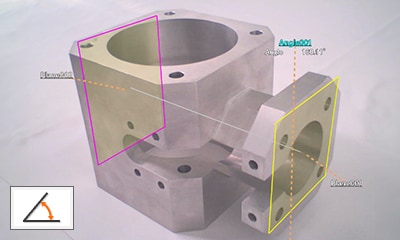

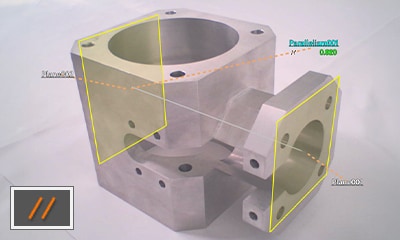

Distance measurement

Angle measurement

Parallelism measurement

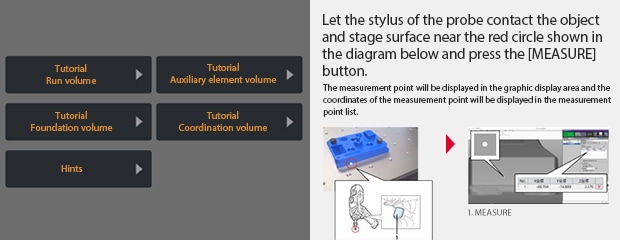

Tutorial Function

The tutorial function provides easy-to-understand measurement instructions with images.

This allows even first-time users to check measurement methods without having to look at the manual.

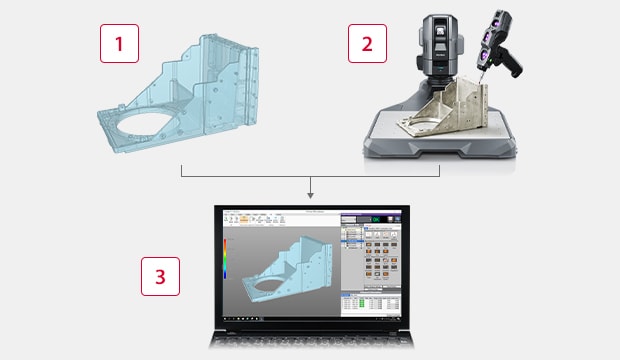

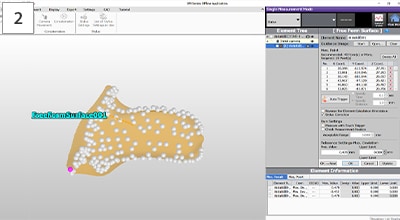

Advanced Features Compare with 3D CAD Data (Optional Accessory: XM-H5C)

-

1Import CAD

-

2Measure

-

3Comparison Measurement

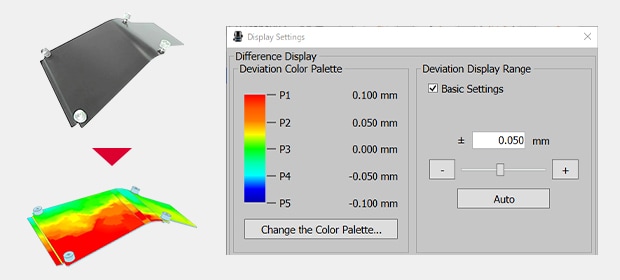

Comparison / Color Map Function

Comparative measurement of parts is possible using the shapes from imported 3D CAD files. The points of difference between the target and the 3D CAD data can also be displayed as a color map.

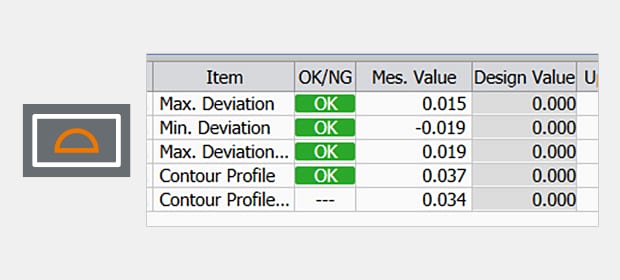

Profile Measurement

Contour profile

A surface profile tool has been added to GD&T measurement elements. This tool makes it possible to measure curved surface shapes.

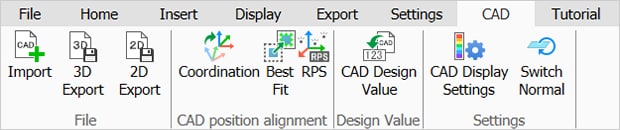

CAD Data Export

3D CAD Export of Measured Elements

Measured elements such as planes, circles, and cylinders can be output accurately to 3D CAD files.

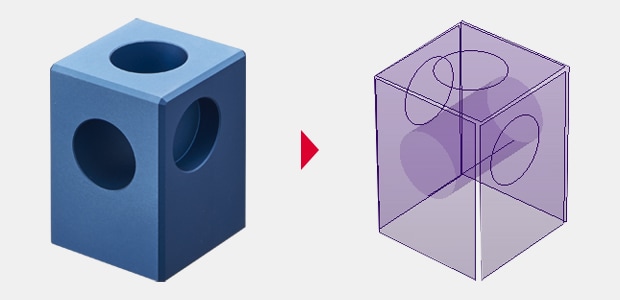

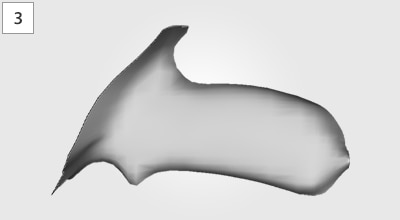

3D CAD Export of Free-Form Surfaces

The XM-5000 can measure and output 3D CAD data even with curved objects simply by touching the probe to the part.

Actual Product

Measure

Example of 3D Export

CAD Export of 2D Elements

Circles and straight lines projected on a flat plane and their dimensions can be output as 2D CAD data (DXF files).