Handheld Probe Coordinate Measuring Machine

XM series

Value Handheld Probe Coordinate Measuring Machine XM series

Auxiliary Functions / Support Statistical Analysis Function for Summarizing Data

Run mode measurement results will be saved automatically to the control PC storage. Saved data can also be extracted for use with various statistical analyses.

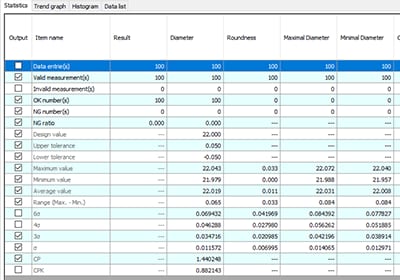

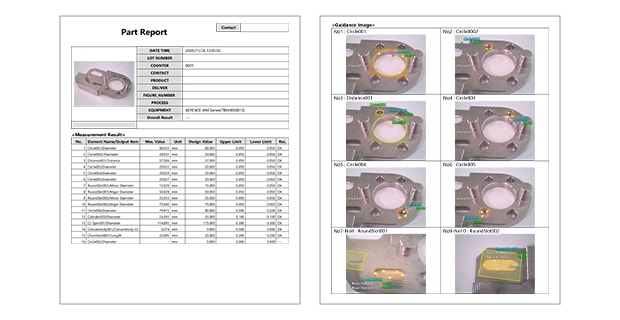

Verification of Statistics Values

Key statistics values such as pass/fail count, max. value, min. value, average, σ, 3σ, 6σ, and Cpk for selected measurement items can be calculated automatically and displayed.

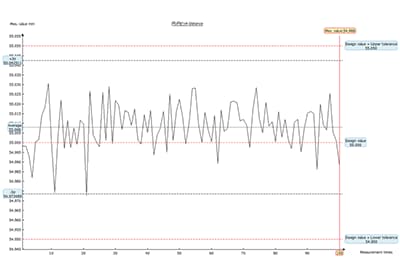

Trend Graph

The trends for selected measurement items can be viewed in a graph. This allows for visualization of such trends as increased variation, upward/downward measurement trends, and periodic fluctuations.

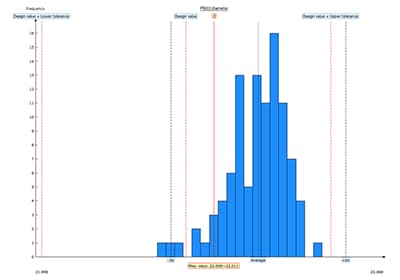

Histogram

The variations for each selected measurement item can be viewed in a graph. The graph, which shows the range of measurements as the horizontal axis and the frequency as the vertical axis, allows users to see whether the measurements are centering on any values in particular and how the measurements vary.

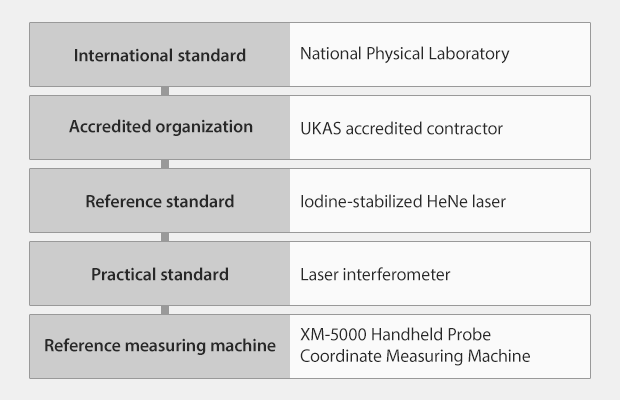

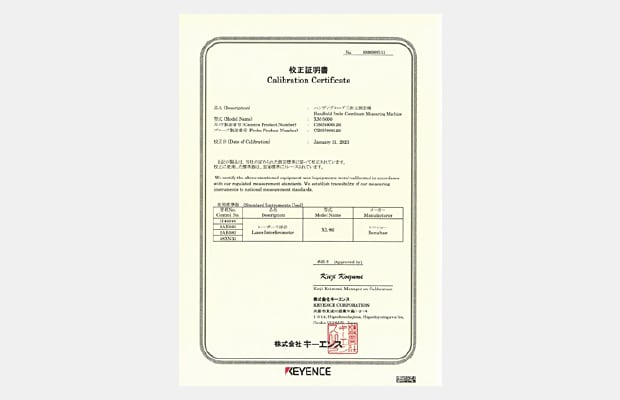

Traceability System Diagram

The laser interferometer used for inspection and calibration has been calibrated by a UKAS accredited company for a traceability system that meets international standards.

Calibration certificate

Follow Up Support

Delivery

After the product arrives, your local system specialist will provide training and assist with system implementation.

Practice Material

Improve proficiency by using the practice materials included with the system.

Technical Support

KEYENCE employs dedicated staff who provide coordinate measuring machine support by phone or email.

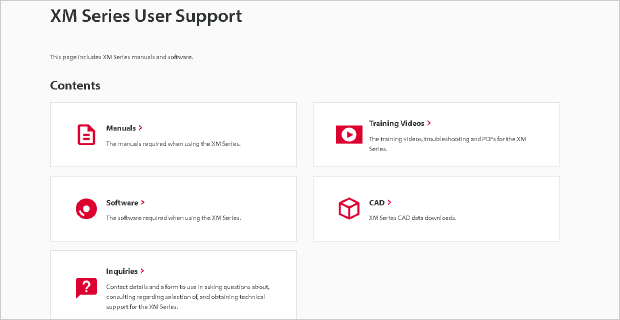

Dedicated Support Site for Improving Usability

KEYENCE offers a user support site accessible only to users of its products. This site includes a variety of easily accessible information such as manuals and software updates.

Easy calibration using the dedicated calibration jig

Simple Stylus Calibration

Simply place the stylus ball tip in the cone of the dedicated jig and measure at least 13 different orientations to complete calibration.

-

1Cone

Advantages of the XM-5000 A Small Coordinate Measuring Machine with the Power to Bring About Big Changes

Improved Efficiency Through Quick and Accurate Inspections

Significantly reduce inspection time by empowering any employee to measure anywhere. This allows for more time dedicated to other critical tasks, enabling shorter delivery times and overall improved work efficiency.

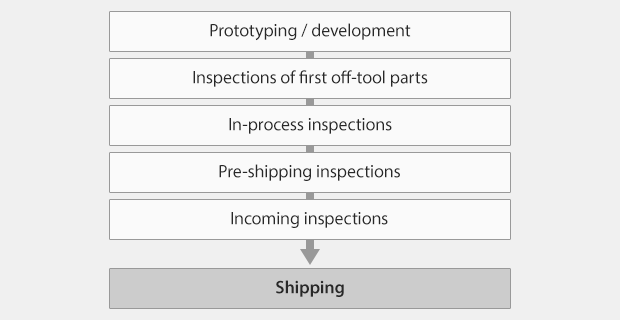

Reduced Costs Through Inspection Process Improvements

The ability to perform in-house inspection can help improve initial yield rates and reduce costs. Delays before shipping and inspection can also be eliminated by performing prompt inspections and quality evaluations during each process.

Acquisition of New Customers

The more advanced a manufacturing request is, the more important access to a coordinate measuring machine is. Being able to tell customers that you have access to a coordinate measuring machine makes it possible to ensure greater quality and to increase the number of handled projects without having to send work to other companies.

Improved Reliability

Manufacturing instructions are becoming more strict every year, and being able to inspect complicated drawing locations can improve reliability with business partners. Moreover, inspection results issued by suppliers can also be reviewed through in-house inspections for greater clarity of process responsibility.