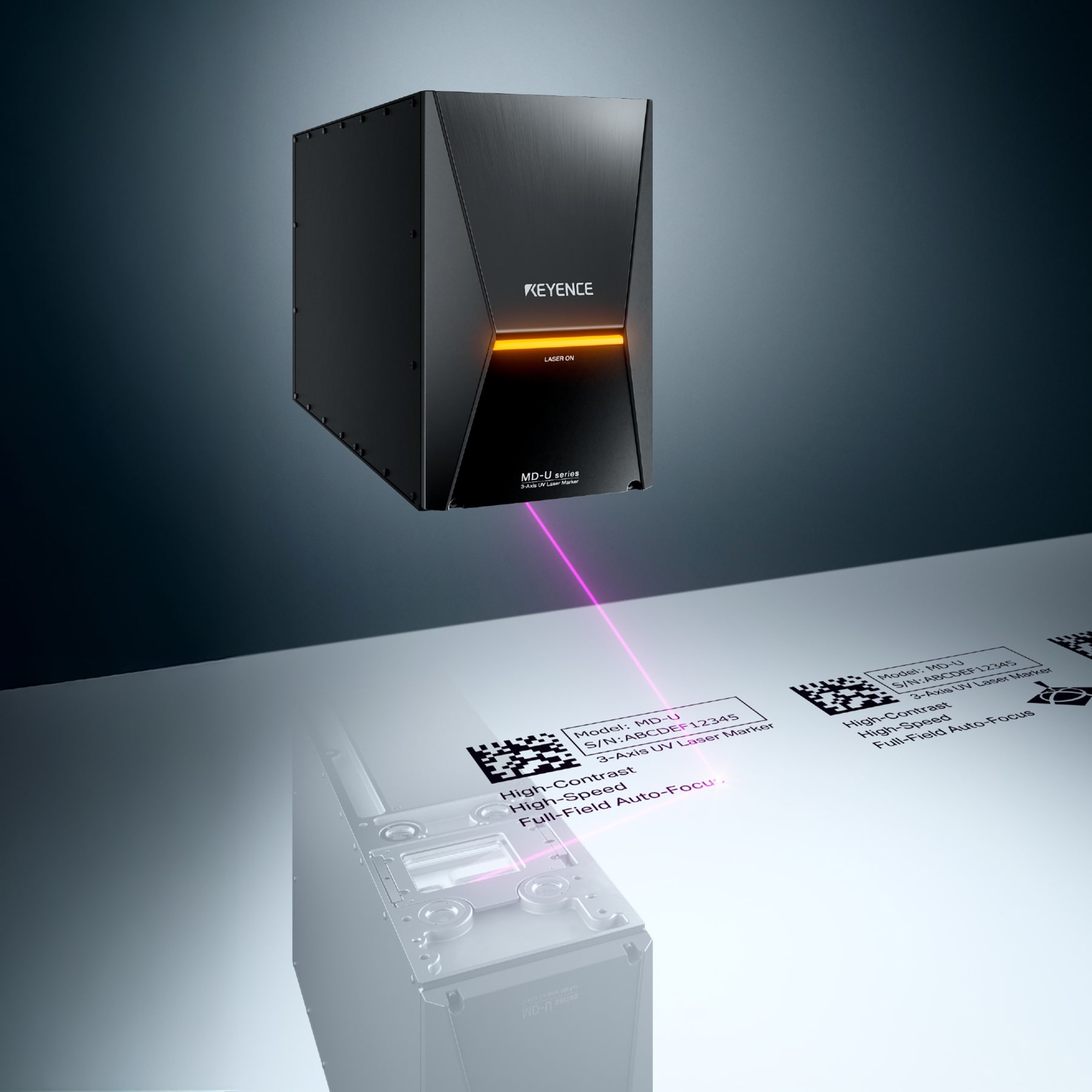

3-Axis UV Laser Marker

MD-U series

3-Axis UV Laser Marker MD-U series

New UV Laser Markers for Increased Precision and Productivity

A characteristic of UV lasers (with a wavelength of 355 nm) is their extremely high absorption rate for various materials. UV lasers allow for high-contrast and damage-free marking and processing in applications where materials with poor visibility and the effect of heat are concerns with conventional standard-wavelength (1064 nm) laser markers. Furthermore, the distance sensor and multi-function camera built into the laser head enable automatic correction of deviations in the distance to the target and in the position while the target is moving. Additionally, the ability to monitor the laser output and to monitor for dirt on the lens prevents marking errors prior to use, allowing for stable operation.

Features

High Quality High Contrast and Damage-free Marking

355 nm wavelength creates high-contrast marking while minimizing damage to the workpiece.

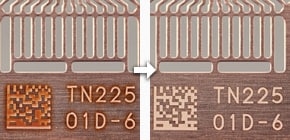

Lead frame (copper)

Easy-to-read marking unaffected by heat.

Relay casing (PP)

High-contrast, highly visible marking.

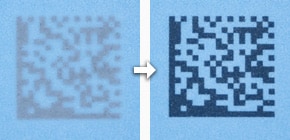

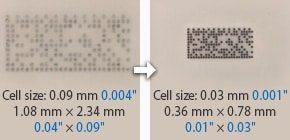

PCB (ceramic)

Extremely small 2D codes marked with high definition.

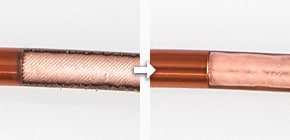

Coils (insulation stripping)

A stripping process that minimizes damage to the core wire.

High Speed Marking in Half the Time of Conventional Models

Marking time is substantially reduced due to improved digital scanner control and increased laser power (7 W at the workpiece surface).

Full-Field Auto-Focus Automatic Correction of Focal and Positional Misalignment

Built-in distance sensor and cameras track workpiece positioning and correct for misalignments, preventing marking defects.