Wide Area CMM

WM-6000 series

Wide Area CMM WM-6000 series

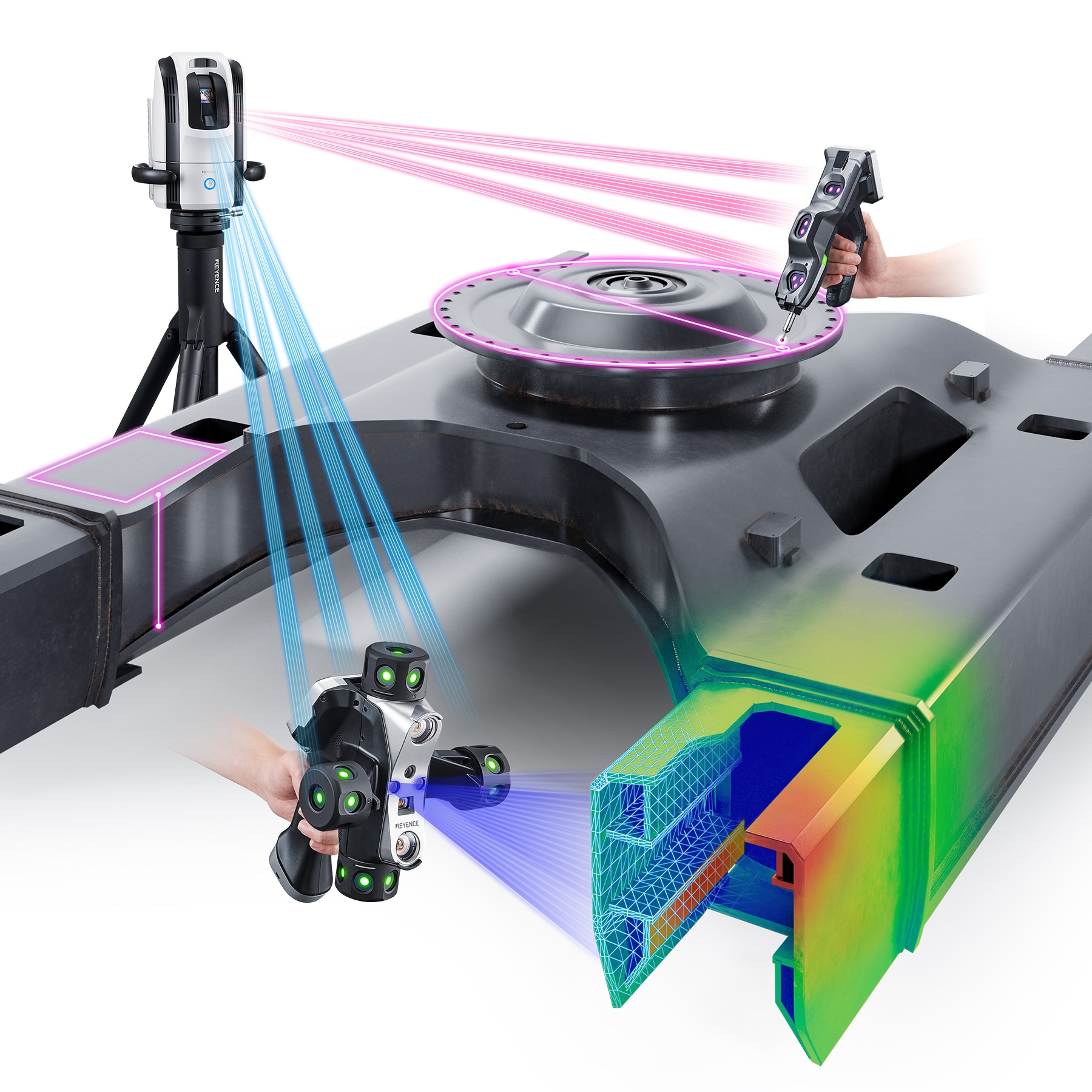

Portable Handheld 3D Probing and Scanning System

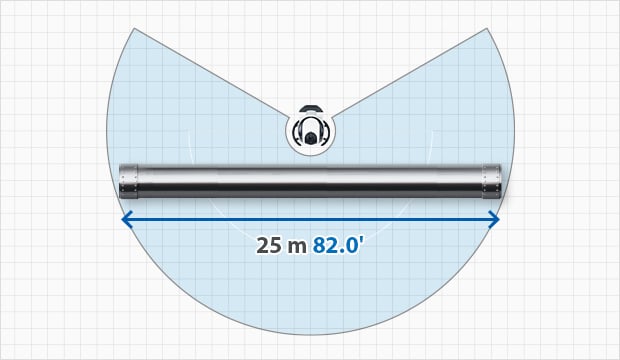

- Wide measurement range of up to 25m (82ft).

- Easy single-person measurement for large parts, assemblies, and equipment.

- Portable and wireless for measurement anywhere.

- Contact probe for 3D/GD&T measurement and a new laser-scanning probe for shape and form measurement.

The Wide Area CMM WM-6000 Series of measuring instruments can easily measure the dimensions and shapes of products. Dimensions can be measured with the contact probe and shapes with the laser-scanning probe. The wireless probes eliminate routing limitations, allowing for easy measurement over a wide range. With no need for preprocessing such as spraying and sealing, scanning can be performed quickly and with high accuracy.

Features

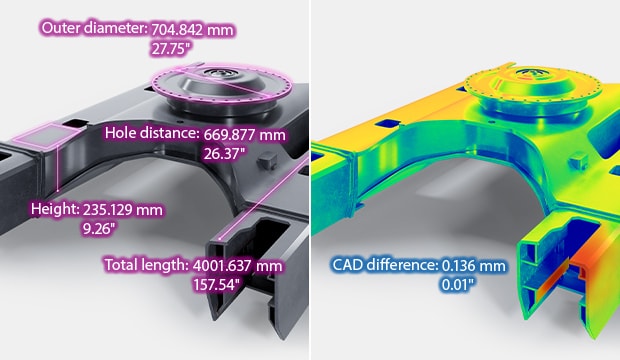

Wide Range of Capabilities, Including 3D/GD&T and Shape Measurement

Choose from two probe types for measuring hole distance and other dimensional features, as well as curved surfaces and complex shapes.

Contact Probe for Dimensional Measurement

NEW Laser-Scanning Probe for Shape Measurement

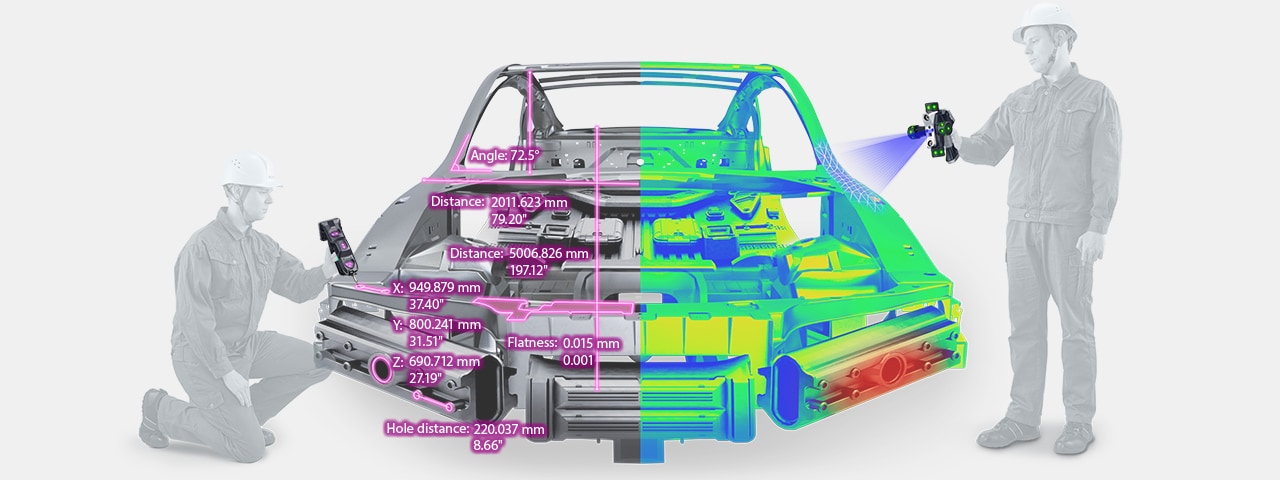

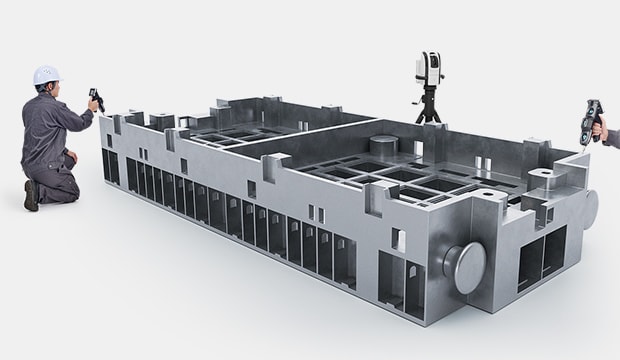

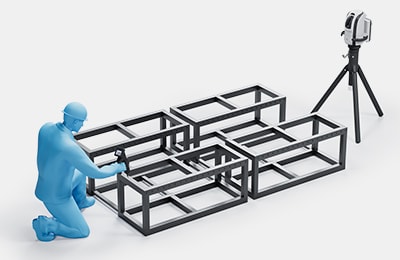

Easy Single-Person Measurement of Large Targets

With a measurement range of up to 25 m 82.0', single-person measurement is possible for targets of any size. This wide range makes the WM valuable when working with large targets, assemblies, and equipment across multiple industries.

![[2 m 6.6'] Doors and other automotive components / [5 m 16.4'] Cabins and other construction machinery / [10 m 32.8'] Shipbuilding parts / [15 m 49.2'] Steel frames and other construction components / [25 m 82.0'] Heat exchangers, large pipes, and other plant components.](/Images/series_wm_features_05-01_2276470.jpg)

Easy to Use for Anyone, Anywhere

Easy Single-Person Operaition

The wide range and touch-screen probe allows for single-person measurement, even on large targets. Operations are controlled from the handheld probe, ensuring simple, smooth operation for anyone.

On-Site Measurement

With its portable size and a temperature range between 0 to 40°C 32 to 104°F, the WM-6000 is ideal for any environment.

Dimensional and Shape Measurement

The contact probe allows for quick dimensional measurements, and the laser-scanning probe offers full-part profile and comprehensive shape measurement.

WM Solves All Conventional Challenges Alone

Problems with Conventional Rools: 3D Measurement of Large Rargets Is Difficult

Conventional CMMs

Arm CMM / Bridge CMM

Hand Tools

Caliper / Tape measure / Large micrometer

| Conventional CMMs | Hand Tools | |

|---|---|---|

|

Limited measurement range

|

Conventional CMMs

|

Hand Tools

|

|

Difficult to operate

|

Conventional CMMs

|

Hand Tools

|

|

Difficult to maintain

|

Conventional CMMs

|

Hand Tools

|

Solutions with the WM-6000 Accurate Dimensions and High-Resolution Scanning: The Best of Both Worlds

Wide measurement range

Measurement is possible over a wide area, up to 25 m 82.0'.

Easy-to-use

Measurements with no variations are easy and can be performed with the probe’s built-in touch screen.

Maintenance-free

The WM-6000’s self-diagnosis function eliminates the need for maintenance.

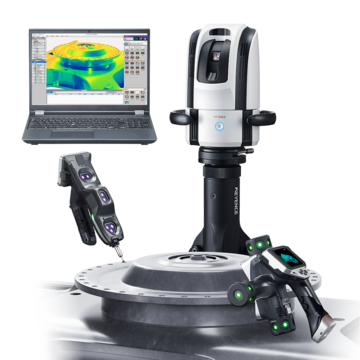

Measurement Principle New Three-Camera Principle for High-Accuracy, Wide-Area Measurement

The WM-6000’s new measurement principle uses a tracking camera to capture near-infrared light from the probe markers. Meanwhile, the probe search camera and reference camera ensure high-accuracy measurement over a wide area.

-

1Probe marker

-

2Reference camera

-

3Tracking camera

-

4Probe search camera

-

5Probe marker

High Accuracy Tracking Camera

The tracking camera offers high-accuracy detection of the position and orientation of the markers on the probe held by the operator.

Tilted to the left

Center

Tilted to the right

High Accuracy Reference Camera

The reference camera uses a built-in chart for highaccuracy measurement of the camera angle without the need for typical encoders (±120° to the left or right, and±30° up or down).

Wide Field of View Probe Search Camera

The probe search camera instantly recognizes and tracks the light emitted by the probe, allowing measurement to be performed anywhere within the wide measurement area.

Measurement Range Redefining Measurement Range with a New Concept

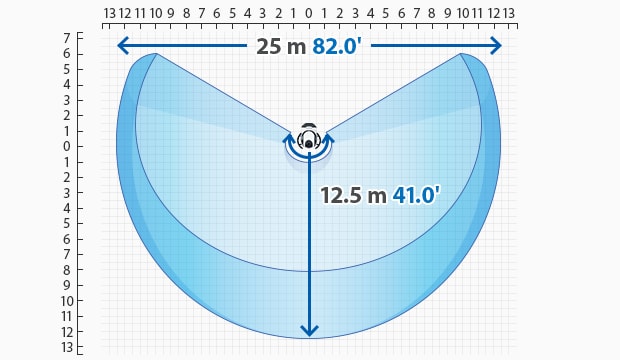

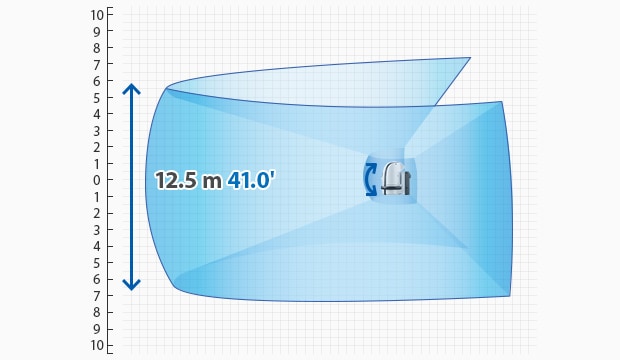

Measurement is possible even for large targets anywhere within the measurement range (25 m wide × 12.5 m deep × 12.5 m high 82.0' × 41.0' ×41.0').

Measurement range in the horizontal direction (m feet)

Measurement range in the vertical direction (m feet)

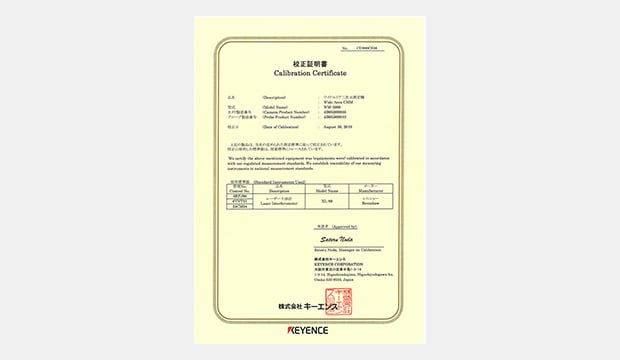

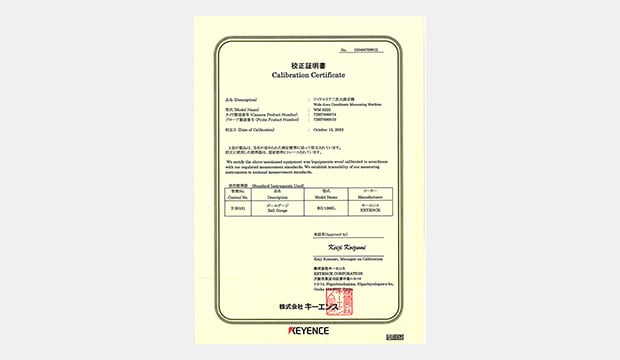

Traceability That Supports Accuracy

Calibration of the WM’s camera and probes are traceable back to an accredited calibration laboratory that complies with international standards.

Contact probe traceability:

- International standard: National Physical Laboratory (NPL), etc.

- Accredited organization: UKAS-accredited company, etc.

- Practical standard: Laser interferometer, etc.

- Reference measuring machine: Wide Area CMM WM-6010/6025/6210/6225

Laser-scanning probe traceability:

- International standard: National Institute of Advanced Industrial Science and Technology (AIST)

- Accredited organization: JCSS-accredited manufacturer

- Practical standard: Reference ball gauge

- Reference measuring machine: Wide Area CMM WM-6210/6225

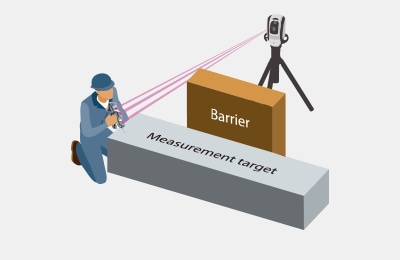

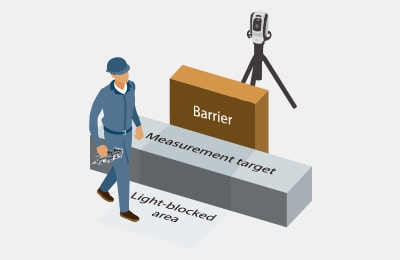

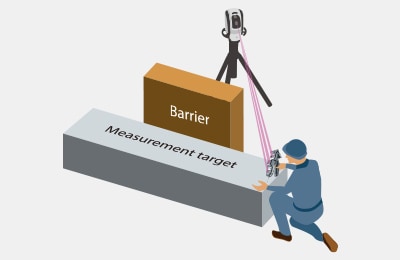

Effortless Measurement with the Probe Search Camera

Even if the light emitted from the probe markers is temporarily blocked, the probe position is automatically detected when the light is visible again, allowing for smooth measurement without having to worry about losing connection to the camera.

Measurement possible

Measurement not possible

[Automatic detection] Measurement possible

Measurement Range Measurement of Targets Over a Wide Area

Measurement is possible even for large targets anywhere within the measurement range (25 m wide × 12.5 m deep × 12.5 m high 82.0' × 41.0' ×41.0').

Measure Anywhere in the Measurement Range

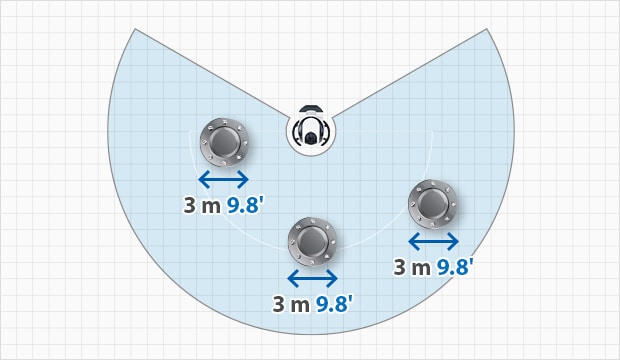

The WM-6000’s wide measurement range allows for single-person measurement even of large products that would require 2 or 3 people with conventional measurement methods.

Measure Multiple Targets from a Single Location

While conventional methods require moving the measuring system or the targets when measuring multiple targets, the wide measurement range of the WM-6000 makes quick, on-the-spot measurements possible in multiple places.

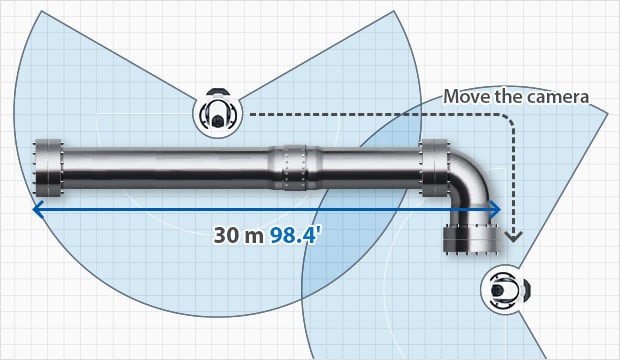

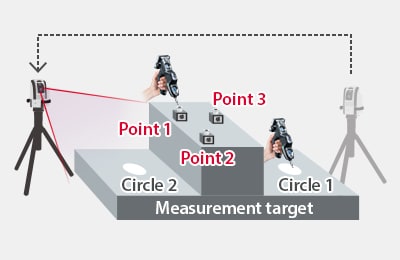

Measurement Range Stitching

The Camera Movement function makes measurement easy even for large targets that do not fit into the camera’s field of view, or complex equipment that blocks the camera’s line-of-sight.

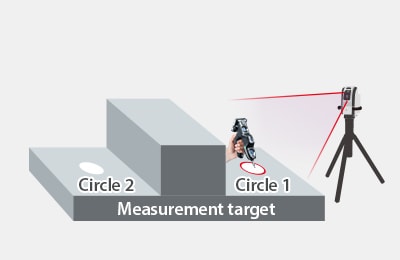

Simple Three-Step Movement Process (Example)

Step 1

Measure Circle 1.

Step 2

Measure points 1 to 3, move the camera, and measure points 1 to 3 again.*1

*1 The OP-88546 or OP-88754 can also be used to measure the three points.

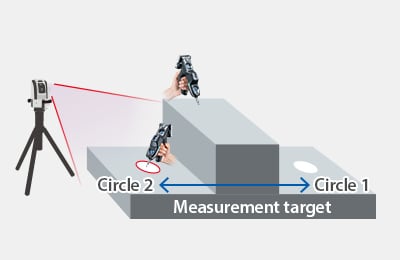

Step 3

Measure Circle 2, and then calculate the distance between Circle 1 and Circle 2.

NEW Wireless Connection Between Camera and PC for Greater Flexibility

Adoption of wireless communication between the camera and PC eliminates the need for the PC to be near the camera and target.*1 This allows for use even in tight or limited spaces and also makes moving the camera easier, expanding the range of applications.

*1 The WM-WL (WLAN unit) is required for wireless communication.