Multisensor Measurement System

Three Parts of a Multisensor Measurement Device

As the world of manufacturing continues to shift into a more modern age, the discussion around multisensor measurement devices expands. This is partly due to a production and economic need, as well as an inevitability from advancements in automated technology.

Multisensor measurement devices come in many shapes and sizes, with an array of unique features to accomplish many manufacturing tasks. However, understanding the parts, functionality, and differences can be confusing. This article provides a clear look at three parts of a multisensor measurement device to offer a better understanding of how the machines work.

What Are Multisensor Measurement Devices?

Multisensor measurement systems are metrology tools used in industrial settings for comprehensive measurement and inspection tasks. Unlike traditional measurement devices that rely on a single sensing method, these use multiple measurement sensors and technologies to capture a broader range of measurement data.

To provide detailed measurement data from every angle, multisensor devices are becoming a vital part of manufacturing. These devices offer a blend of automation and manual use cases, but the tool’s efficiency and accuracy are unmatched.

You can break down a multisensor system into many different parts, but there are three that are known to carry a majority of the weight.

We’re here to provide you with more details.

Reach out today!

Three Main Components of Multisensor Measurement Systems

The key components of multisensor technologies include the confocal laser, touch probe, and high-resolution camera. These components enable multisensor systems to function effectively and enhance efficiency in manufacturing processes.

While the specifications of these components may vary across different products, their fundamental functionality remains consistent. Each component plays a crucial role in enabling multisensor technologies to meet the diverse needs of manufacturers.

With a range of options available for lasers, probes, and cameras, there's ample variety to address specific manufacturing requirements. However, it's essential to carefully review the specifications of these components and multisensor systems to ensure they align with the intended application. This way, you don’t end up with the wrong product for the job.

Fortunately, multisensor measurement technologies are becoming increasingly standardized, comprehensive, and user-friendly, making them accessible even to those new to the technology. Regardless of the specific type of multisensor measuring instruments, the confocal laser, touch probe, and high-resolution camera serve as the foundational components of the system.

Confocal Laser

Seen as a top choice over triangulation laser, confocal laser offers the benefit of a single optical axis. This eliminates dead zones while allowing the machine to see exactly where it needs to be. Better yet, you can enjoy no loss of data near step height changes either.

Another benefit of this type of laser is that it can accurately measure curved surfaces. No matter where the machine is in the measurement range, data accuracy will always remain intact. It boasts efficiency even with extremely uneven surfaces.

Touch Probe

Sometimes, contact measurement is a necessary part of the manufacturing process. Cone angles or edges that are tricky to pick up with the lens are applications where a touch probe can be handy. Also known as contact probes, touch probes are one of the most common parts of multisensor measurement technology.

Ultra-High Resolution Camera

Cameras are core components of effective multisensor measuring instruments. These high-resolution cameras provide a visual that can be referenced and generate a broad range of data points on what's being inspected.

Ultra-high-resolution cameras are important in capturing detailed visual information for precise measurement and analysis tasks. The cameras feature superior resolution capabilities, enabling them to produce clear, high-quality images with exceptional clarity and detail.

By providing a comprehensive visual of the part or component being inspected, the camera facilitates accurate measurement and analysis of dimensions and geometric characteristics.

Discover more about this product.

Click here to book your demo.

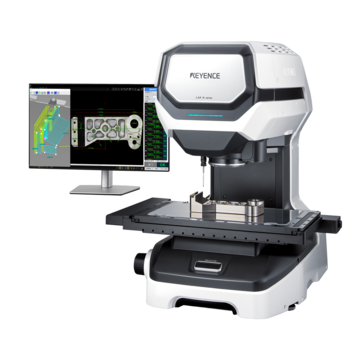

Discover the KEYENCE LM-X Multisensor Measurement System

For those looking to streamline manufacturing processes and improve measurements, the LM-X multisensor measurement system from KEYENCE is all you’ll ever need. It can measure up to 5,000 different locations on up to 1,000 parts at one time.

Also, the multisensor machine can easily inspect a wide variety of materials, part sizes, and shapes. In addition to that, the system is extremely intuitive to use. It is as easy as pressing a button, and you can navigate the different measurement methods we spoke about above, from touch probes to lasers and high-resolution cameras- place, press, and obtain results.

These are great for getting an extremely accurate report of all part dimensions. Employees will appreciate a minimal learning curve with the device, as it utilizes intuitive software that anyone can learn.

Other notable benefits of this multisensor include:

- Non-contact height measurements

- High-speed measurements, reporting, and overall output

- Heavily reduces measurement time of complex parts

The LM-X Series embodies the most modern, high-end multisensor equipment in recent years. Between being user-friendly, growing a rapport with manufacturers, and benefiting the end consumer, the LM-X is seen as a must-have investment in manufacturing.

Final Thoughts

Manufacturers are being pushed to adopt modern equipment and technologies to remain a competitive force in the market and adapt to increasing consumer demands. To address that need, multisensor measurement systems, like KEYENCE’s LM-X Series, can provide the necessary capabilities to improve operations.

If you have any questions about multisensor equipment or measurement technologies, contact KEYENCE today. Our team can further explain these parts and how to integrate the right machines for your needs.

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

Brochure for the LM-X Series Multisensor Measurement System. Using optics, probes, and a multi-color laser to automatically measure all of your parts features.

Brochure for the LM-1100 Series High Accuracy Image Dimension Measurement System. Submicron accuracy part inspection with non-contact height measurement.

Brochure for the IM-8000 Series Image Dimension Measurement System. Accurately measure parts in seconds at the push of a button.