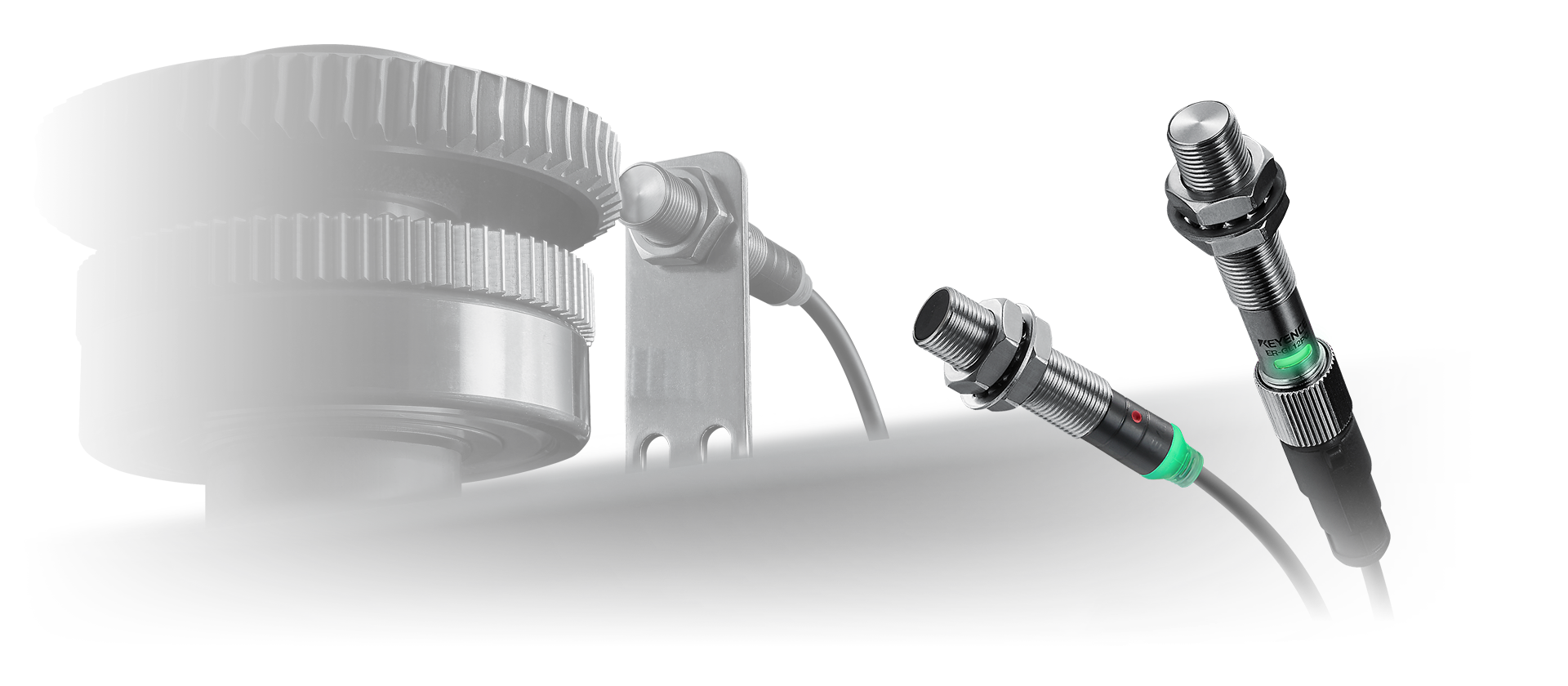

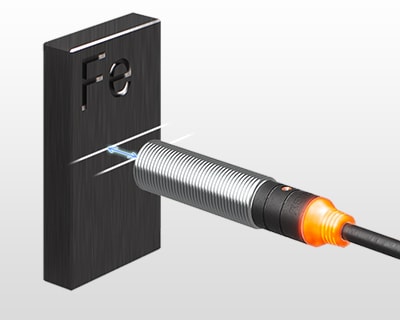

Inductive Proximity Sensor

ER series

-

Unparalleled long-distance detection

-

Superior impact and abrasion resistance

-

Designed for ease of use

Improved durability ensures stable operation in any environment. The ultra-long distance model offers four times the detecting distance compared with conventional models. This increased range helps reduce the risk of damage from impacts and abrasions. The all-metal models go even further to protect the sensor by featuring a stainless steel detection surface for superior environmental resistance. A full lineup of specialized models is also available, including compact all-metal types for tight spaces, environment-resistant all-metal types with IP68G/69K protection, and weld-resistant all-metal types with a ceramic coating that prevents spatter adhesion.

Features

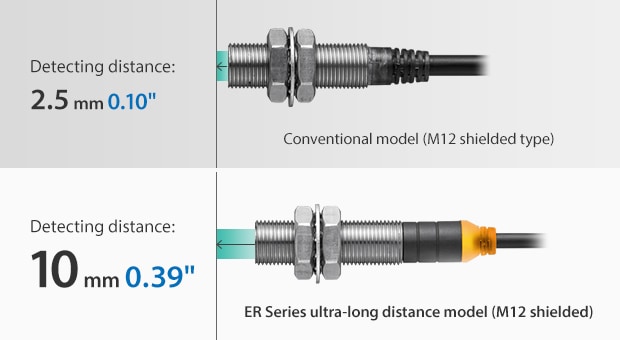

Ultra-Long Distance Model with 4x the Detecting Distance of Conventional Models

The ER Series enables ultra-long distance detection, allowing installation farther from the target, greatly reducing the risk of damage caused by impact and abrasion. It also prevents false detections caused by vibration or misalignment. The new Pulse oscillation + Dual-coil detection method enables flush metal mounting and long-distance detection without interference from surrounding metal.

All-Metal Models Provide Superior Protection

Conventional proximity sensors feature a plastic detection surface, making them more prone to damage due to impacts and abrasion. However, with the all-metal model of the ER Series, the detection surface is protected behind a metal housing that improves durability and reduces the likelihood of damage. This series also includes several different types of all-metal models to ensure reliability in a variety of environments and applications.

Conventional Model

Plastic detection surface has a greater risk of damage

ER Series All-Metal

All-metal detection surface offers superior protection

Four All-Metal Models to Suit Any Application

General-Purpose Type

Up to 7mm 0.28″ of range for a wide range of applications

Compact Type

For installation in tight spaces

Environment-Resistant Type

For reliable use in harsh environments

Weld-Resistant Type

Ceramic coated for stable detection in welding environments

Designed for Ease of Use

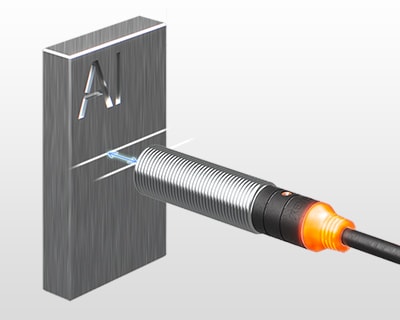

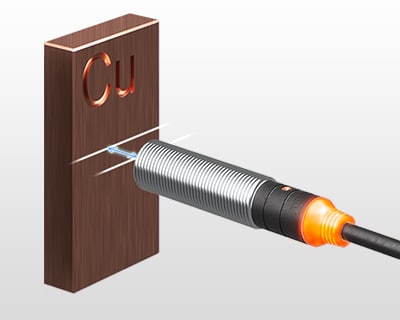

The ER Series offers innovative features that solve common problems faced by conventional proximity sensors. For example, the large 360° status indicator makes checking the sensor status easy from any angle, even at a distance. Improved resistance to metal debris and spatter during processing also ensure stable detection in harsh environments. Stable long-distance detection is possible even for non-magnetic materials such as aluminum, which previously made detection difficult.

Large, Easy-to-See 360° Status Indicator

[Constant green] OFF

[Off] Power off

[Constant orange] ON

[Flashing orange] ON

Matching level notification

Improved Resistance to Metal Debris and Spatter

No false detection due to metal debris

* With non-magnetic metal debris and spatter.

Detection possible even with metal debris

Long-Distance Detection of Aluminum, Copper, and Stainless Steel

Aluminum

Copper

Stainless steel