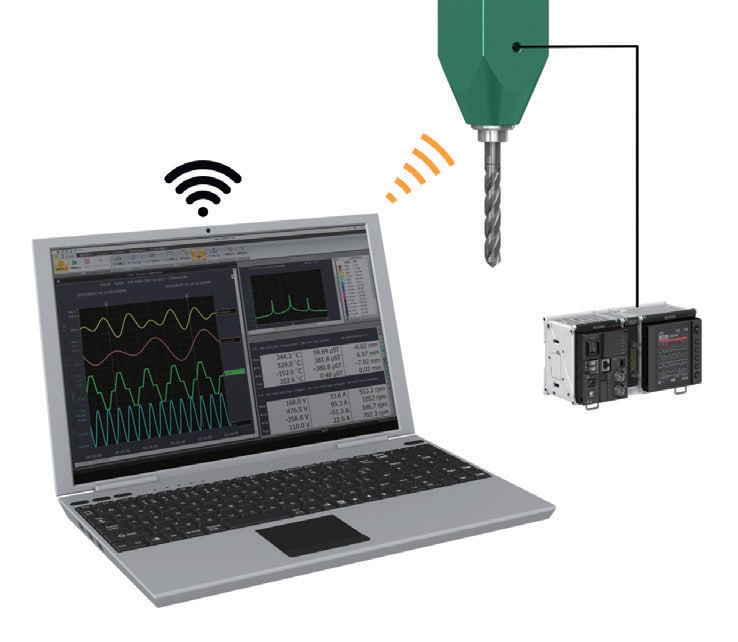

Data collection for processing machine tool run-out and vibration

-

Industry:

- Automotive, Metals

-

Products:

- Data Acquisition

Sensors are installed on processing machines to measure and record the run-out and vibration of tools. By comparing against data obtained during proper processing, you can identify, for example, tool deterioration and tool chuck errors. Comparisons like this are also useful for predictive maintenance, as you can detect changes from normal run-out and vibration at early stages. Maintenance and replacement before tools deteriorate or break helps reduce defective products, making your production more efficient and stable.