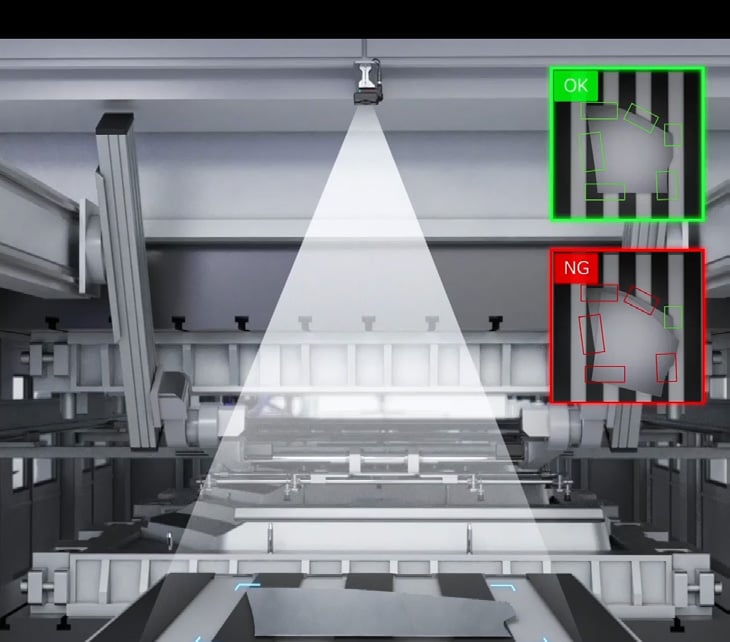

Blank Misaligned Press Detection

-

Industry:

- Automotive

-

Products:

- Machine Vision

Misalignment detection is the primary objective, and double feeding is a secondary objective. The transfer press has a feed mechanism that lifts from below and sends the piece on to the next process. Misaligned pressing occurs when idle pieces are placed incorrectly, and this may damage the mold in the next aperture process. Every press has aperture processing, but transfer presses require detection more than most as they (1) are susceptible to misalignment on the feed mechanism, (2) have a greater plate thickness than a servo, making the mold susceptible to damage, and (3) work at high speeds.