Double Blank Detection

-

Industry:

- Automotive

-

Products:

- Machine Vision

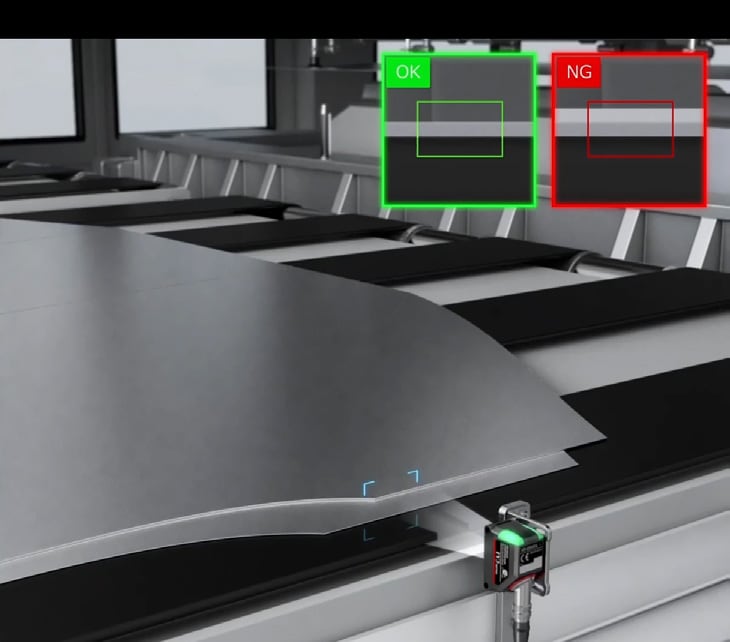

Even though a DB sensor (double blank sensor, eddy current-type sensor) is installed, adjustments are often difficult and the yield rate is poor. - Eddy current-types do not react unless the installation distance is changed when thickness changes. - If the distance is too far, it interferes with the piece and breaks, or damages the piece. - When double feeding occurs the phase of the first blank and the second blank differ, and the DB sensor does not react. When double feeding occurs, the piece itself is discarded, and the mold may be damaged. Due to the intense bend at the leading edge and trailing edge of the roll, a phenomenon called “corrugation” occurs. For this reason, both reflective and clamping models negatively affect detection with an eddy current sensor(interference, poor reaction). As the number of mechanical assemblies increases, contact sensors become difficult to use from a durability aspect. Lasers are environmentally difficult to use. With the IV Series, double-feeding can be detected from the side.