Slide Parallelism Measurement Automation

-

Industry:

- Automotive

-

Products:

- Sensors

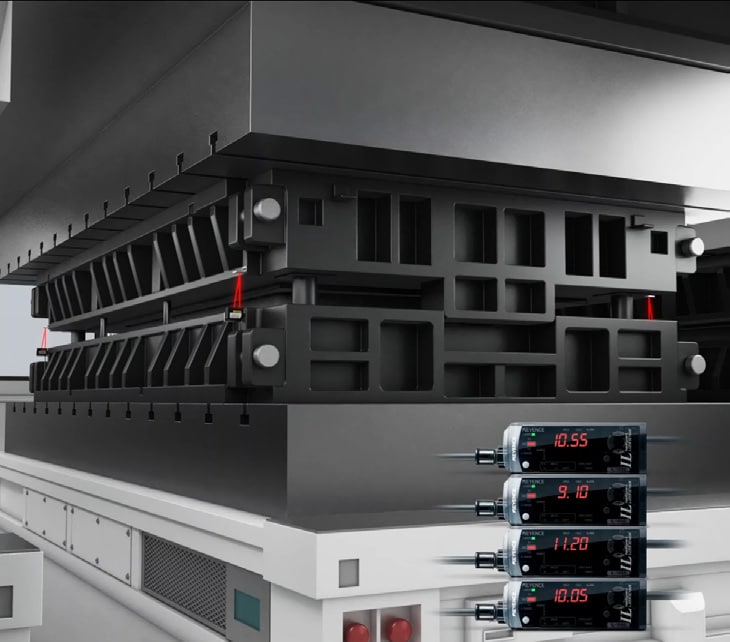

This reduces the man hours required for measurement. The keyword is “slide parallelism.” It depends on the country, but measurement once per year is specified as an inspection item. That one time is a cumbersome task. When the reference position is set to 0, it is necessary to move the slide mechanism to 9 positions while measuring the value of the bottom dead center at each position. There are also 7 or 8 other measurement points, and it is necessary to measure how much deviation there is.