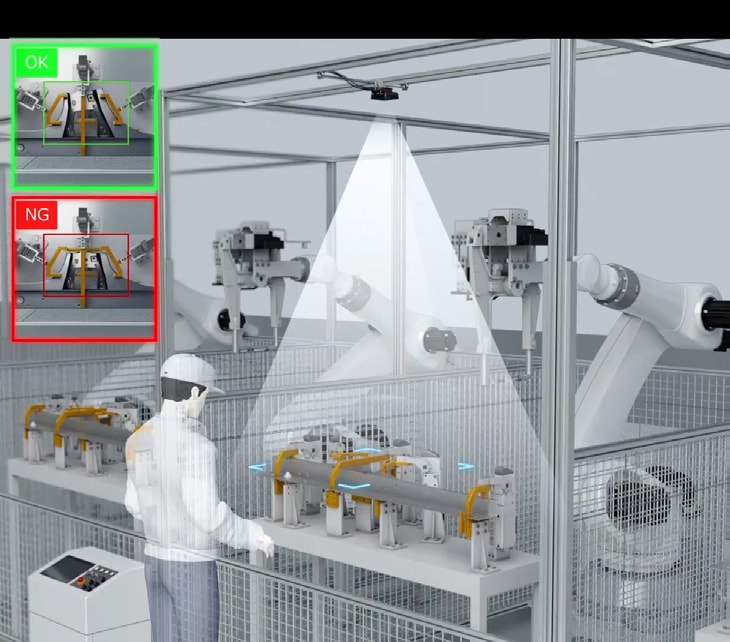

Pre-Welding Model Detection

-

Industry:

- Automotive

-

Products:

- Machine Vision

For combinations of general-purpose sensors:- Reduction of issues caused by temperature changes in the factory. - Reduction of the man hours needed to add new models. Conventional vision systems: - Overwhelmingly strong against ambient light. To begin with, model detection is to prevent the wrong parts from moving on to the incorrect next process when multiple items are placed on a general-purpose jig for welding. Conventional method: Presence detection of holes and forms using proximity and lasers. Problem 1: Erroneous detection and reconfiguration resulting from the occurrence of fluctuations in response to the proximity sensor and strain on jig due to changes in ambient temperature. Problem 2: Extra man hours required due to needing to configure the sensors each time a model is added. There are many requests for a change to vision systems to address the problems, but there were erroneous detections and detection was not stable due to the occurrence of changes in the way images appear as a result of the impact of ambient light caused by the expansive space unique to a car body factory. The IV Series enables stable detection that eliminates the unstable elements of a conventional vision system as much as possible by using 24 times the conventional amount of light + learning tools.