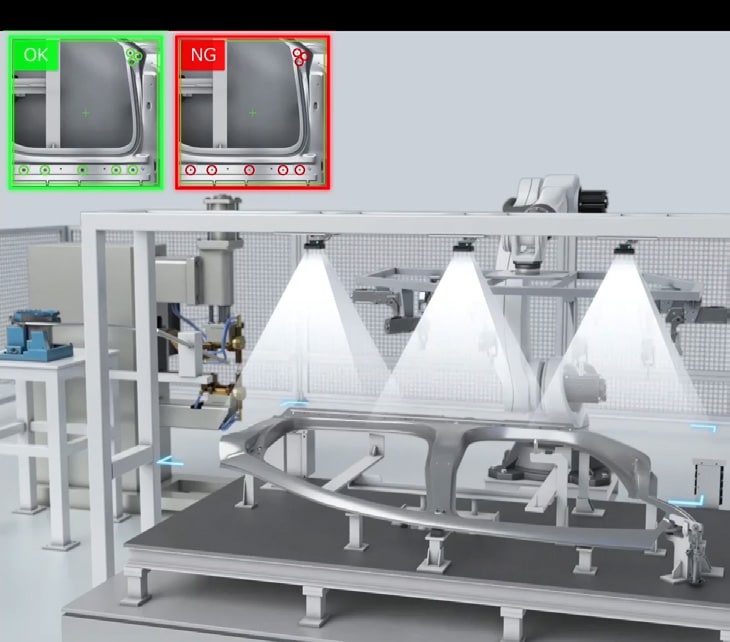

Nut Presence Detection

-

Industry:

- Automotive

-

Products:

- Machine Vision

Because defects are not discovered until reaching the assembly line, when a defect occurs it is necessary to remove coatings to make corrections, requiring a very large number of man hours. Ji Kotei Kanketsu (JKK) enables reduction of man hours when a defect occurs. Checking the presence of nuts is generally separated into (1) measures using manned equipment and (2) measures using unmanned (robotic) equipment. A risk shared by both methods (1) and (2) is the occurrence of the loss of man hours for 1. receiving a coated body for correction, 2. coating removal, and 3. re-welding, because defects are discovered in final assembly in the flow of body ⇒ coating ⇒ assembly.