Model Differentiation

-

Industry:

- Automotive

-

Products:

- Machine Vision

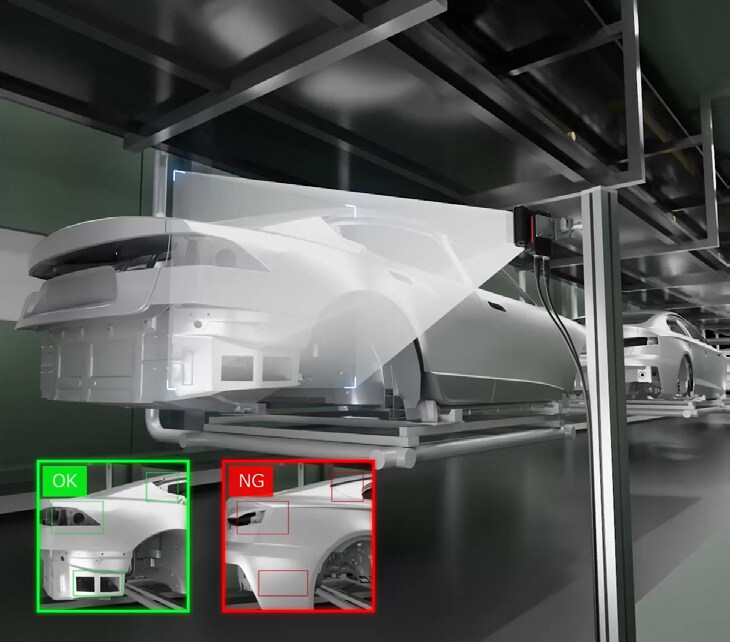

Makes it possible to change the voltage and current before electrodeposition, prevent coating cart tilt defects before reloading, prevent sealing defects and robot interference before sealing, and prevent coating defects and robot interference before the middle and top coating. Production instructions can be clearly written, but errors by workers made to remember instructions and RFID reading errors. In particular, in the case of electrodeposition, the body is discarded if the above issues occur, so this must be prevented. In combinations with photoelectric sensors, erroneous decisions are made due to chattering caused by hanger vibration, etc. Furthermore, each time a model is changed or added, it is necessary to install and change the positions of the transmission sensors in the coating process, and perform optical-axis alignment of projected and received light. The way images are viewed by vision systems varies in coating factories because LEDs turn on and off during operation. However, stable detection is possible if the IV Series learning tool is used.