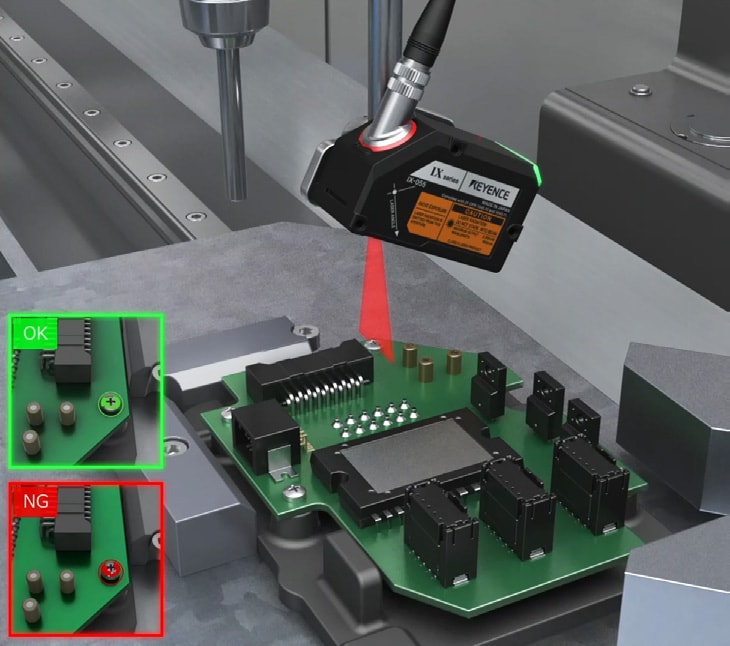

Detection of Screw Tightening Height

-

Industry:

- Automotive

-

Products:

- Sensors

This enables the detection of raised screws after tightening. If the screws are not tightened properly, this could cause power defects for a PCB, or the entire product deviating from the dimension tolerance in later processes if it is another assembly part. For this reason, screw height is an essential confirmation item. In general, torque management problems are caused by angled screws, and even if they are embedded to the base due to a molding defect on the receiving side, they are deemed to be OK in terms of torque when a load is applied. The problem with contact sensors are cases where there is a lack of space because multiple units are required when attempting to detect raised screws based on differences from a reference position. Furthermore, on a line with multiple item types, the sensor position must be changed, and man hours are also required for programming.