Torch/Arm Position Confirmation

-

Industry:

- Automotive

-

Products:

- Sensors

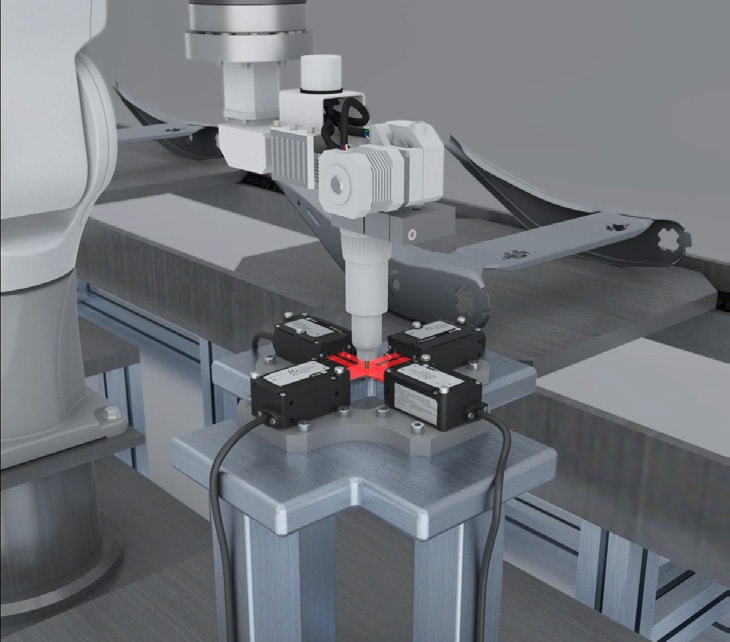

By monitoring the deviation of the position of the tip of the torch arm, it is possible to prevent defects caused by deformation of the tip such as deviation of the weld line due to the welding torch position and deviation of the runner position due to the nut runner. Deformation occurs because load is applied to the torch arm tip when the robot is operating. For this reason, it is necessary to install sensors in the robot standby position to check whether there are any deviations in the X, Y and Z direction. It is possible that deviations of several millimeters in torch position will not be noticed with the human eye because automated machinery is constantly moving. Furthermore, if processing or assembly are performed while the arm tip is deformed, there is a risk of mass producing defective products.