Detecting Double Blanks in Ceramic Plates

-

Industry:

- Automotive, Electronic Devices

-

Products:

- Sensors

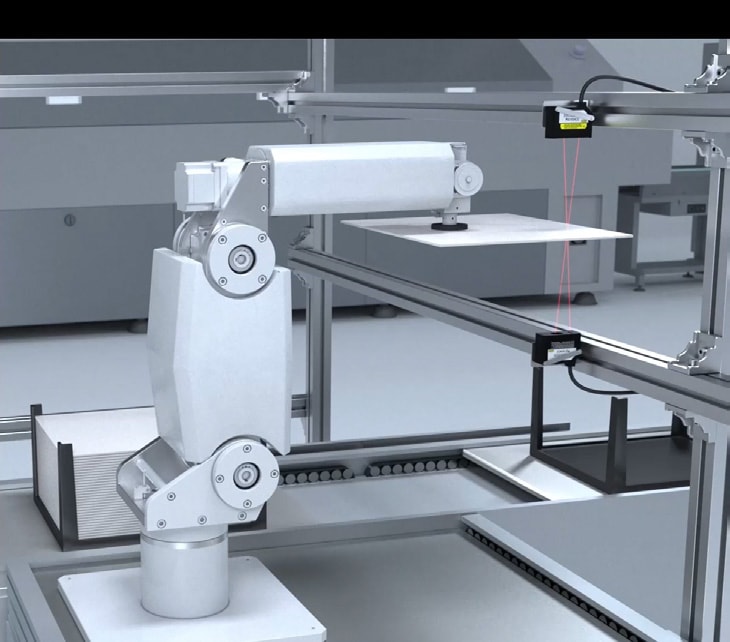

A ceramic plate is positioned on the core contact area before coil assembly. The ceramic plate is transported by a suction conveyor. In order to ensure that two plates have not stuck together due to static electricity, the thickness is measured during transportation. With the IL Series, there is no need to perform calculations with a PLC because calculations can be made and configured by the sensor itself. In addition, settings are automatically configured according to the gloss level and surface condition of the piece, thereby enabling reliable detection.