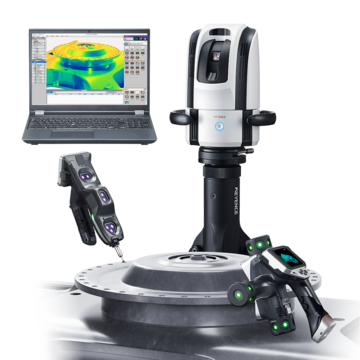

3D Scanner

Comparing Structured Light Scanners vs. Laser Scanners

Discover the key differences between structured light and laser scanning technologies, exploring how each method captures 3D data, their strengths in precision and speed, and which applications benefit most from their unique capabilities.

What is a Structured Light Scanning?

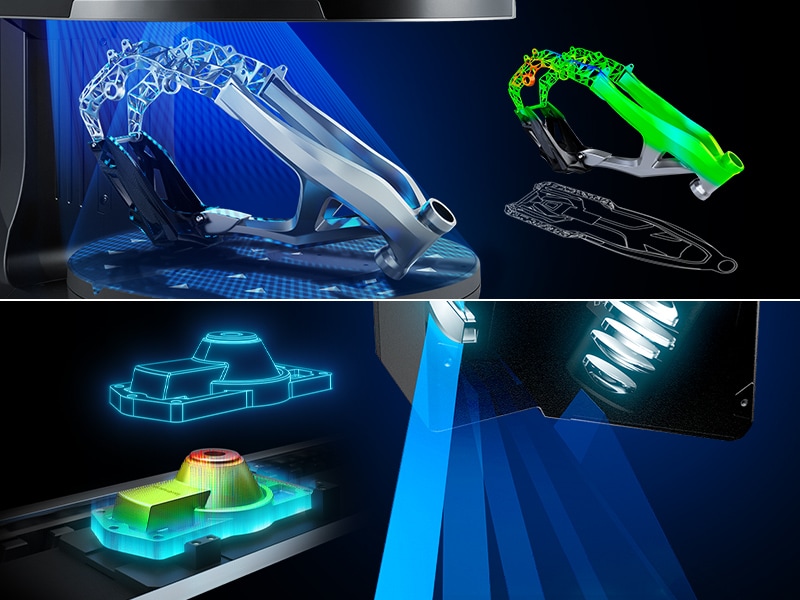

Structured light scanning is a 3D scanning technology that employs projected light patterns onto an object's surface. The process involves projecting a known pattern, often a grid or a series of lines, onto the object. A camera, positioned at a different angle, captures the distorted pattern resulting from the object's surface geometry. By analyzing these distortions, specialized software reconstructs a detailed 3D model of the object.

We’re here to provide you with more details.

Reach out today!

Differences Between Structured Light Scanners and Laser Scanning

The way a laser scanner collects 3D data on a surface is similar to a structured light scanner; however, the light source is a laser and the projected pattern is simply a laser line or multiple laser lines. These devices scan a surface line-by-line instead of an entire area at once.

How Structured Light Scanning Differs from Laser Scanning?

Light Source

- Structured Light

- Uses projected light patterns (grids, lines, etc.).

- Laser Scanning

- Utilizes laser beams to measure distances.

Accuracy

- Structured Light

- Generally offers high accuracy and capturing fine details for parts within the system’s working area through environmental and ambient-lighting control.

- Laser Scanning

- Focused on capturing large-scale objects over a longer range with accuracy dependent on laser color, scan pattern, and other capabilities.

Speed

- Structured Light

- Tends to be faster, making it suitable for applications where efficiency is crucial. Entire areas can be scanned at one time.

- Laser Scanning

- May require more time, especially for detailed and complex objects. Projects a single or multiple lines for collecting surface data.

Complexity of Objects

- Structured Light

- Well-suited for capturing complex geometries and intricate details.

- Laser Scanning

- Effective for scanning large, simple objects or environments.

Environmental Considerations

- Structured Light

- Sensitive to ambient light conditions; works best in controlled environments.

- Laser Scanning

- Performs well in various lighting conditions, including outdoor settings.

Material Dependence

- Structured Light

- Highly-reflective or transparent objects may require the application of a scanning spray to accurately capture surface details.

- Laser Scanning

- Able to scan any surface, regardless of material.

Structured light 3D scanners and laser scanners are both invaluable tools for 3D scanning, each with its strengths and applications. While structured light scanning excels in capturing intricate details with speed, laser scanning proves efficient for large-scale objects and diverse environments. The choice between the two depends on the specific requirements of the project and the nature of the objects being scanned.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us