Wide Area CMM

WM-6000 series

Hardware Wide Area CMM WM-6000 series

Measure Anything, Anywhere

The portability of the WM-6000 eliminates the need to move targets, making it possible to measure targets wherever, whenever. The use of a tripod or wagon also enables setups that meet a variety of specific needs.

Ready to Use in Just 2 Minutes

Ease of setup:

The WM-6000 can be set up and ready for measurement in just 2 minutes with no difficult settings to configure or warm-up time.

1. Transport

The WM-6000 comes with a dedicated mobile case.

2. Set up

Simply install the WM-6000 on the tripod.

3. Measure

Use immediately.

Quick, Easy Measurement Anywhere

Excellent portability with no controlled environment required:

The WM-6000 has been meticulously designed with a focus on making a PCMM that can be used anywhere. With no need for a controlled environment, the WM-6000 can be used for measurement in a wide variety of locations using a tripod, extension pole, or wagon.

Tripod

Extension pole

Wagon

New Easily Adjustable Height

Tripod with built-in height adjustment:

The dedicated tripod is designed to be durable and reliable for use in harsh environments. The new adjustable height function takes this one step further by adding support for tall targets.

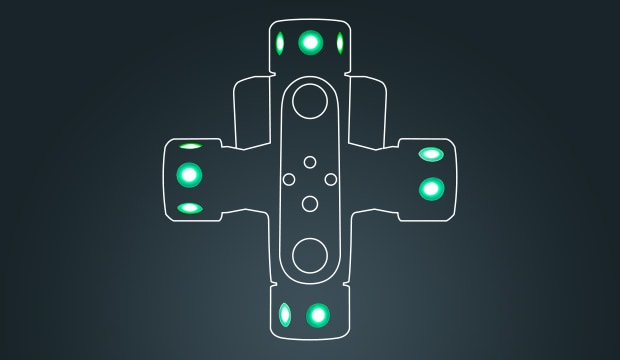

Just Touch the Part with the Probe No Movement Restriction with the Wireless Probe

The wireless probe allows for measurement from any angle, making it easy to use for anyone. The probe also features a built-in touch screen for use during measurement.

-

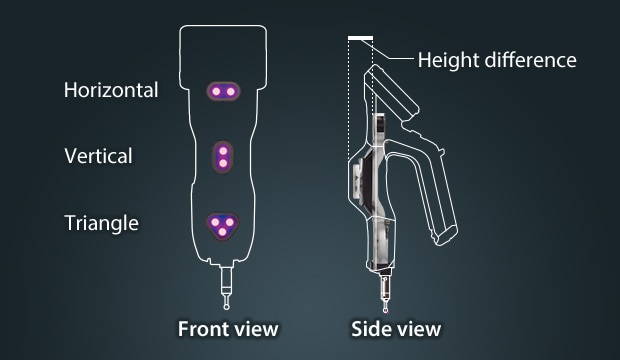

1Probe marker layout for high accuracy

-

2Probe detection status indicator

-

3Integrated construction for minimal measurement variations

Placing markers horizontally, vertically, in a triangle, and at different heights helps ensure high-accuracy measurement.

The all-in-one structure reduces measurement errors, and an additional cushion structure also prevents contact damage.

Easy Access to All Functions

Touch screen operation:

The probe includes a built-in touch screen that offers access to the same operations as a PC and can be used to display measurement results. The display is also pressure-sensitive, so operation can be performed even when wearing gloves.

-

1MEASURE button

-

2CANCEL button

-

3OK button

Intuitive Operation for Anyone to Use

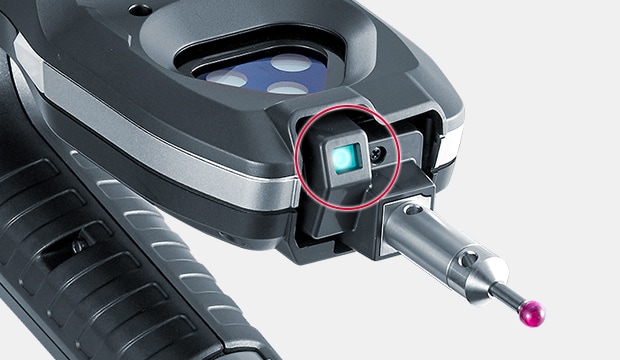

Built-in probe camera:

The compact camera in the probe tip can be used to capture images that can be overlaid with measurement results. This makes it easy to understand where measurement is performed, ensuring intuitive usability for all operators.

Changeable Stylus to Suit Each Measurement Location

Easily replaceable probe tips:

The WM-6000 stylus can easily be changed whenever needed to make measurement more convenient.

*1 Commercially available products.

Hemispheric stylus

Stylus extension

Needle stylus

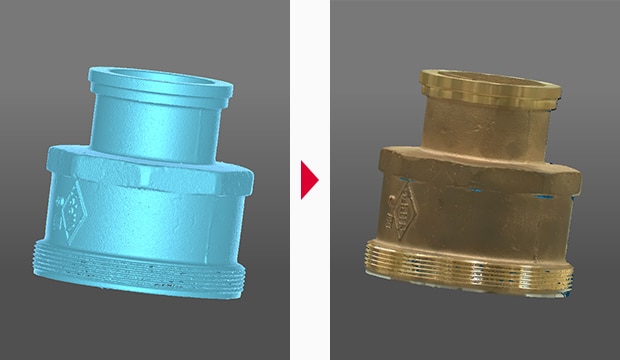

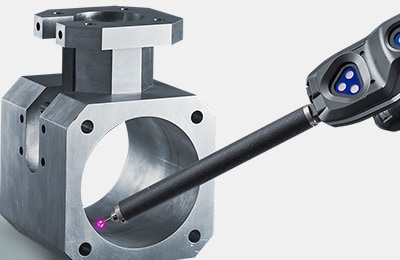

NEW Laser-Scanning Probe for Greater Measurement Flexibility

With no encoders or joints like arm CMMs, the WM-6000 can scan from any angle, making it easy to use for anyone.

-

1High-power laser for measurement, even on glossy surfaces:

The high-power laser makes scanning possible even for glossy, mirrored, or plated surfaces, which are difficult to scan with conventional tools. -

2Multi-line laser for high-speed scanning:

The WM-6000’s 30 line lasers (15 on each side) ensure high-speed scanning even for large targets. -

3Texture camera:

The texture camera is used to determine and save the surface conditions of the scanned target for later use. -

4Laser receiver cameras

-

5Probe marker positioning for eliminating blind spots

The wide dynamic range of these cameras makes scanning possible for virtually any target.

The probe is equipped with 7 different markers in 4 different directions for a total of 28 probe markers. This allows users to adopt a more flexible approach to scanning.

NEW On-Screen Scanning Confirmation

Built-in touch screen:

The probe includes a built-in touch screen that offers access to the same operations as a PC. The ability to check real-time results eliminates the need for constantly referring to the PC. This ensures reliable scanning of all measurement areas.

-

1Scan start/stop button

-

2Display mode button

-

3Zoom buttons

NEW Smooth Scanning of Any Target

Built-in violet laser:

The built-in 405 nm violet laser emits sharp, high-power laser beams for smooth scanning of any target. Output can also be switched to a single high-power laser for plating and other mirror surfaces.

Multi-line laser

Single high-power laser

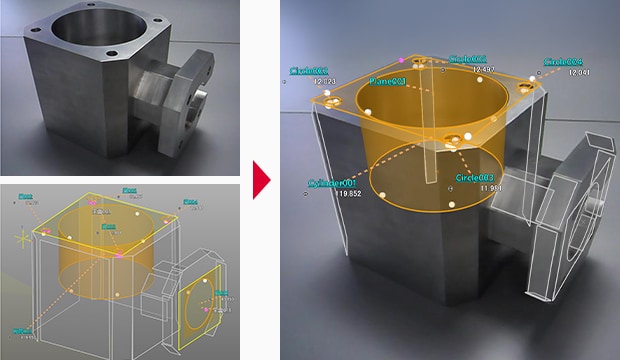

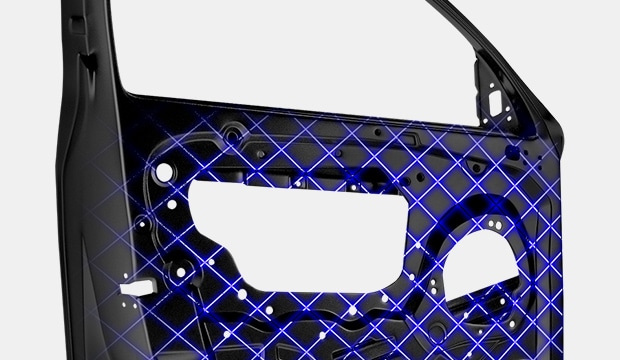

NEW Surface Condition Checking

Texture camera:

Scanned data can be overlaid with images using the texture camera for improved visibility of joints in welded and assembled products. Processing instructions and marking lines can also be saved on the images.