Roughness measurement examples: Chemical and Raw Materials Industries

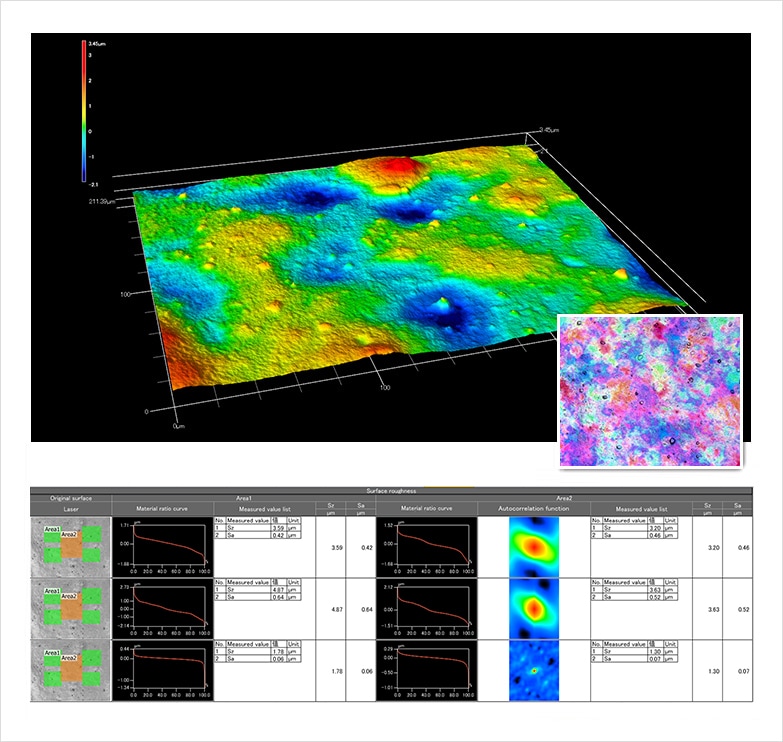

Effects of printing on paper quality — Sa (Arithmetic mean height) / Sz (Max. height)

Film surface

Sa and Sz analyses are effective for numerical management of film roughness. Analyzing film surfaces not only helps reduce oversights but also can help with ensuring stable quality of multi-layer films, managing glossiness, and more. In addition, using non-contact type measuring instruments ensures that the shape of the target is not affected.

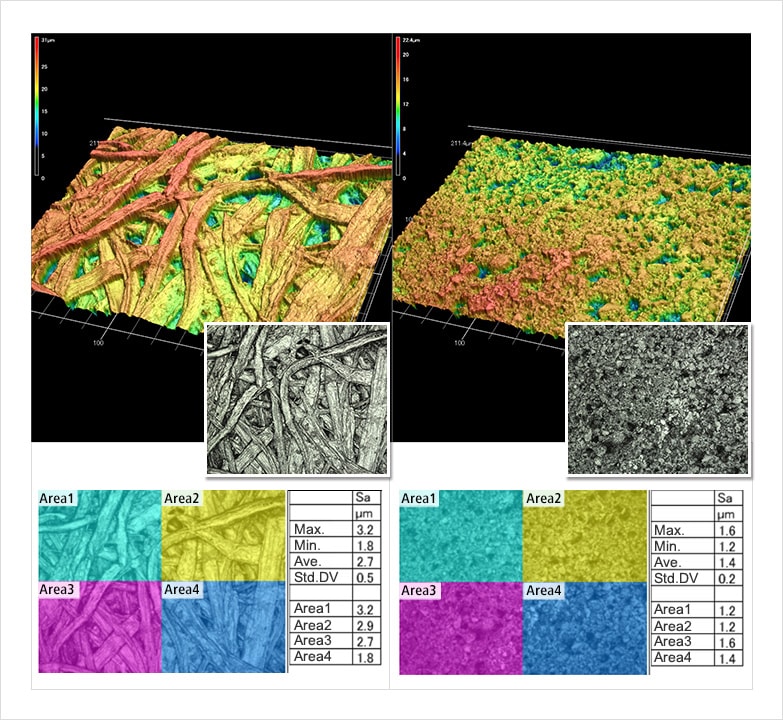

Effects of printing on paper quality — Sa (Arithmetic mean height) / Rsm (Average length of elements)

Comparison of printing paper

When it comes to influencing print quality, surface smoothness is an important factor. Although Ra analysis is often used for evaluations, more reliable evaluation is possible by looking at Sa values, which take into consideration the entire surface. Looking at the entire surface of a product when analyzing quality is an effective means of evaluation. Analyses such as Rsm, which looks at cyclical unevenness, are also effective.

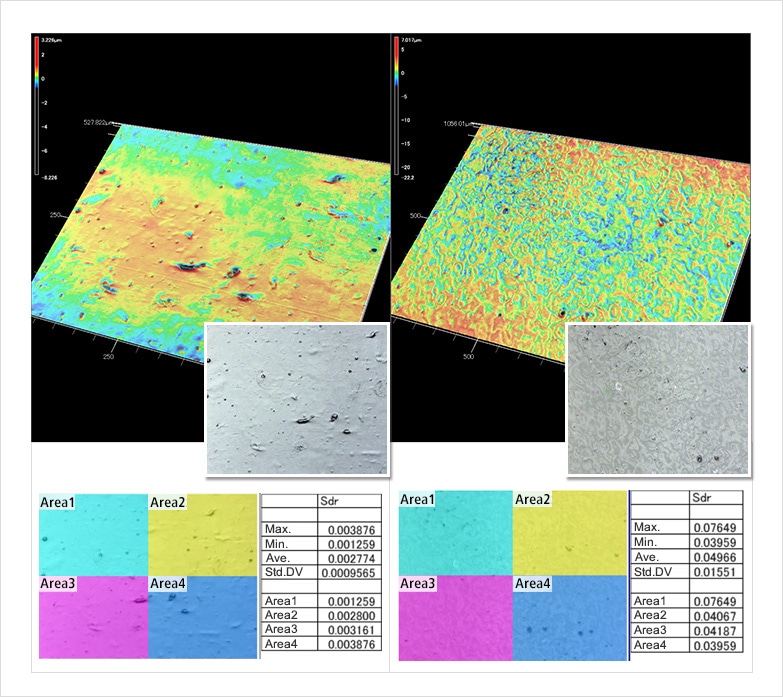

Evaluation of adhesive force of tape employing different manufacturing methods — Sdr (Developed interfacial area ratio)

Adhesive tape

Sdr analysis can be used to look at how sticky an adhesive material is according to the production method of the adhesive tape. Sdr analysis allows for a proportional expression of increase for an actual surface area with the object being flat as the reference, allowing for numerical management of the degree of surface area increase.