Reducing inspection time and cost through automated colony counting

Delica Foods introduced the BC-1000 High-Accuracy Automated Colony Counter from KEYENCE to reduce manual counting and cut down on inspection costs at their Kanagawa location. Although they’ve only been using the system for a short while, it has already helped to reduce the number of Petri dishes by approximately 25,000 per year. We interviewed Ms. Noriko Makino and Ms. Shino Izawa from the Quality Department, who were both heavily involved in the justification and operation of the BC, to learn more about its implementation, usability, and impact to their business.

Delica Foods Co., Ltd.

Delica Foods Holding Co., Ltd. is developing a wholesale business for whole and cut vegetables. As a vegetable specialty trading company, they provide a one-stop service from cultivation to purchasing, processing, and distribution. Delica Foods Co., Ltd. is a group company that is primarily responsible for vegetable processing.

Delica Foods is dedicated to providing high-quality, safe vegetables on a daily basis to approximately 800 customers across Japan, including major restaurant chains, fast food restaurants, and convenience store vendors.

Get detailed information on our products by downloading our catalog.

View Catalog

Over 200 inspections of cut vegetables per day

How is the BC being utilized?

We use it for microbiological testing on the cut vegetables we produce and sell. We inspect around 15 to 20 items daily, testing each for four types of bacteria: total viable count, coliforms, E. coli, and Staphylococcus aureus, with 1 to 4 dilution levels. On average, I run about 210 inspections a day using the BC.

The inspection system is mainly operated by one part-time worker. However, when that person is unavailable or on vacation, Izawa steps in to assist with inspections.

Since your facility handles both whole and cut vegetables, are inspections focused only on the cut vegetables?

Most of the inspections are focused on cut vegetables.

Cutting them crushes the cells, releasing liquid that provides nutrients for bacteria and lowers the vegetables’ natural resistance, making it easier for bacteria to grow. Since the product isn’t heated before shipping, it has a short shelf life, making it a high-risk item. That’s why a thorough examination is essential.

However, we also inspect whole vegetables. Since our products may contain soil and other particles, we focus on testing for the presence of pathogenic E. coli bacteria rather than measuring general viable bacteria counts.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Reducing inspection costs and labor

How did you first learn about the BC?

I first learned of the BC at KEYENCE’s booth when I visited FOOMA JAPAN, a major food manufacturing exhibition. At the time, we were exploring ways to boost efficiency and cut down on labor in our labs, so were actively searching for a tool to help. Since each of our offices has decision-making authority, we worked with KEYENCE’s sales team to present the benefits of the BC to the plant manager, who gave the go ahead for the equipment.

How much cost savings did you anticipate?

By reducing the counting time and number of dilution steps for each inspection, we expect to save about $300 - $400 a month.

Delica Foods has locations nationwide. Are there any challenges with only having a system like the BC at one location?

Ideally, each of our locations that needs to do microbial testing would have a system. This way, we don’t need to centralize our testing, and we can make sure that our data and analysis are done under the same conditions. I’ve already passed info on the BC along to some of our other quality control departments to see if there’s any interest in implementing it at those facilities.

Reduced Petri dish consumption by about 25,000 annually

How are the expected labor and cost savings in inspections going?

For viable bacteria and other inspections, the BC has reduced our testing time by half. As we become more familiar and expand the usage of the system, I’m expecting to see even bigger labor savings.

As far as cost reductions go, most of the savings that we’ve seen has been from reductions in Petri dish use. Since the BC can accurately count even very small colonies, we don’t need to re-run any of our tests to double-check the counts or adjust dilution levels, which is something we frequently did when manually counting. This has lowered our Petri dish usage to about a third of what we did previously.

This reduction alone saves us around 25,000 Petri dishes annually, translating to several thousand dollars in cost savings. We also anticipate further reductions in expenses as we continue optimizing the system’s use.

Curious about our pricing?

Click here to find out more.

Simple yet highly customizable

How would you evaluate the BC so far?

I think the biggest benefit for us has been how easy the system is to use. However, it’s still very customizable to accommodate some of our more complex counts.

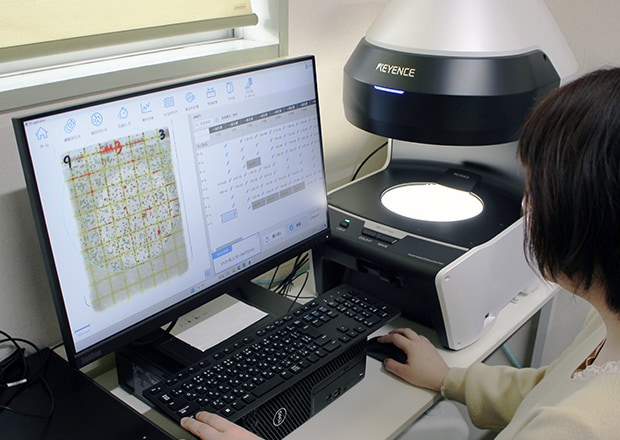

- Simplicity dedicated to counting

The BC is a dedicated counting system with a very easy-to-use interface. This makes operating the equipment quite simple and foolproof. The camera even features an alignment function that automatically adjusts the position of the Petri dish to the proper location. The fact that it can count on both Petri dishes and growth film makes it incredibly versatile. - Highly customizable

Another great function of the BC is its user-friendly design and the capacity to customize settings for each inspection. We can finely adjust the hue, saturation, and brightness settings and then save these adjustments as presets. This has helped us to reduce inspection times and get accurate counts on the different types of samples we work with. - Saves high-resolution photos

An important difference for us between the BC and manual counting or other automated colony counting systems we evaluated was the ability to take a clear image of the Petri dish or film being tested. These images can be reviewed and sent to customers if there are any cases of food poisoning, product discoloration, or concerns with unusual odors. Having both the count data and image archived is incredibly helpful when communicating with customers.

Has the introduction of the BC impacted your information management system?

Yes! Previously, our inspection results were handwritten and manually entered in a database. Now, the entire process is basically automated. The BC counts a sample, exports the data to Excel, which we can then import directly into our LIMS.

It’s been a big time-saver for us and helped to prevent mistakes in data entry.

What are both of your opinions of the BC?

The BC is an excellent system for automating our colony counting processes. In many cases, tools that automate processes can help to reduce workloads, but they usually come at a pretty high cost or require a lot of integration to function properly.

The BC has not only significantly reduced our manual counting workload, but it has also contributed to cutting operational costs, making it a very efficient and cost-effective solution.

What is your outlook for the future?

The Kanagawa Office is considering increasing the number of inspection staff. Additionally, Delica Foods as a whole is in the process of standardizing its inspection methods and regulations.

I would like to create an environment where anyone, regardless of their prior knowledge can accurately perform inspections so long as they have the BC.

Discover more about this product.

Click here to book your demo.