Roughness measurement examples: Automotive and Metal Industry

Analysis of contact surface smoothness — Ra (Arithmetic mean roughness) / Rz (Max. height)

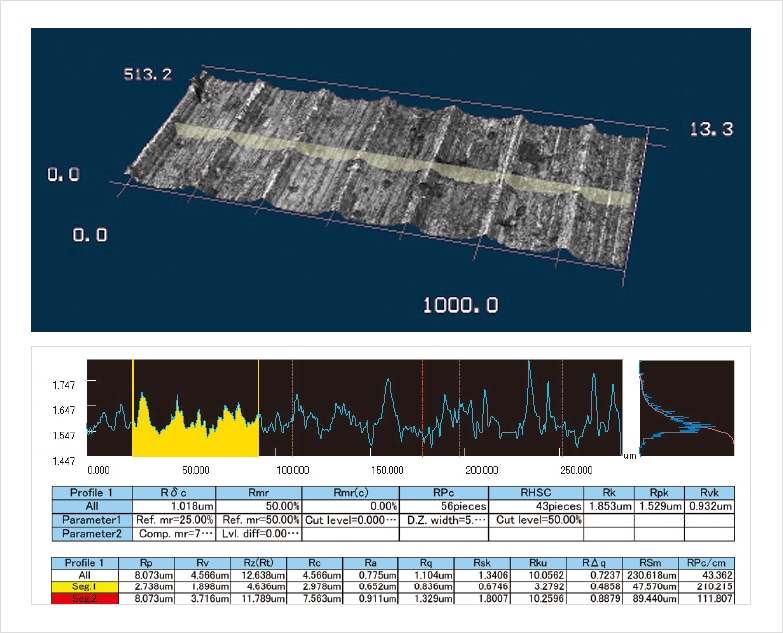

Steering components

Ra and Rz measurements can be used to look at the smoothness of surfaces that come into contact with another surface. Because using Ra alone may cause some points, such as single protrusions, to be overlooked it is important that both Ra and Rz be used together.

Quantification of grindstone quality by looking at roughness — Ra (Arithmetic mean roughness) / Rz (Max. height)

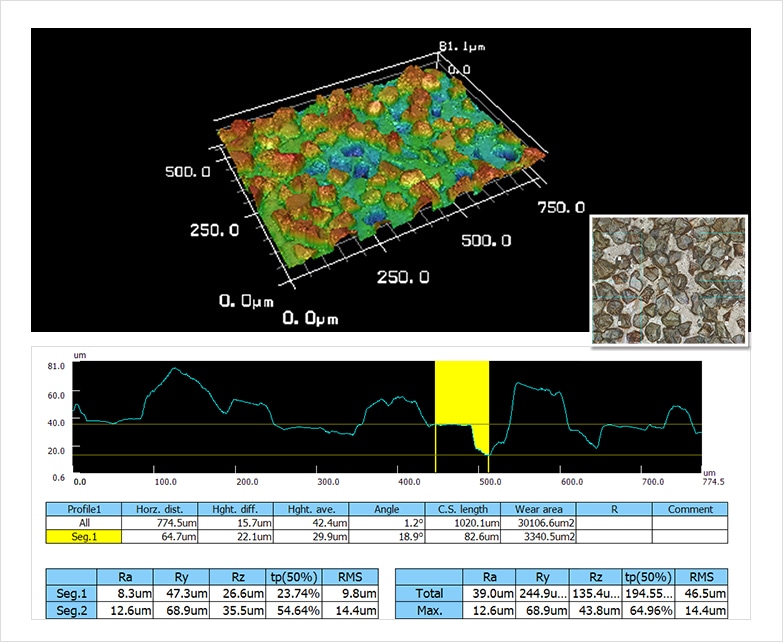

Metal grindstone

Ra and Rz are used to look at the completed condition of the grindstone by looking at the differences in individual grits. Through management using numerical values, stable quality can be assured.

Quantification of differences in metal processing methods — Sa (Arithmetic mean height) / Sz (Max. height) / Str (Texture aspect ratio)

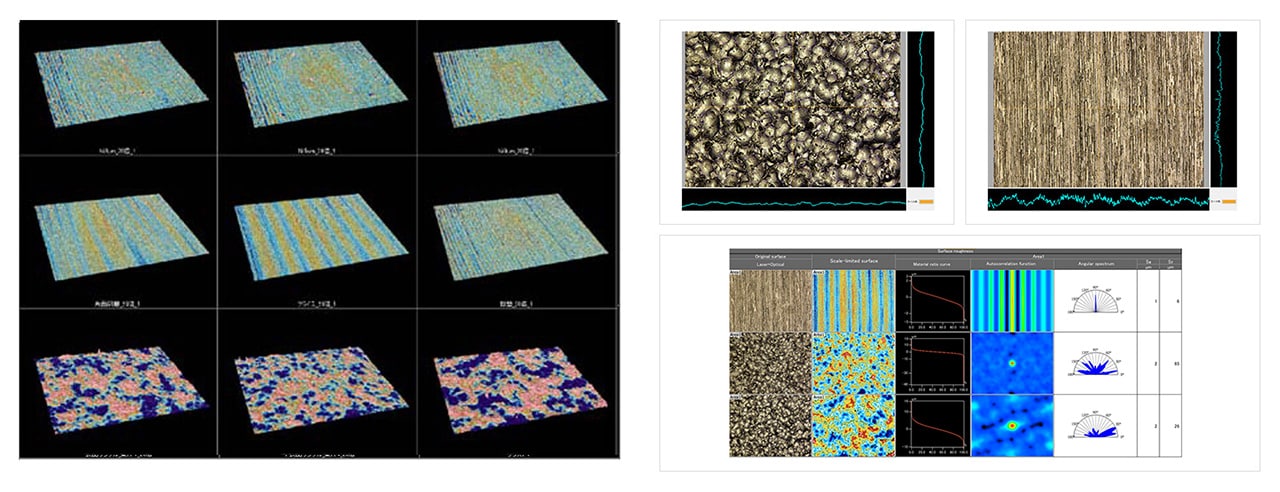

Processed metal surface

This analysis compares changes in surface properties that arise from different processing methods. Sa and Sz analysis looks at the finishing condition, while Str analysis checks whether processing traces can be found in external appearances.

These images are measured by KEYENCE Optical Profilometer.