Roughness measurement examples: Electrical Machinery and Electronics Industries

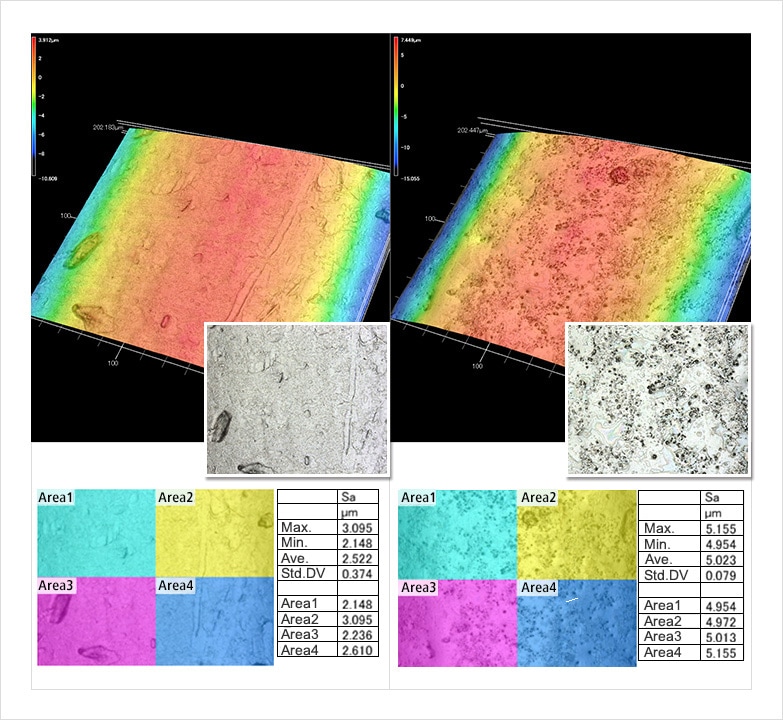

Failure analysis of solder — Sa (Arithmetic mean height)

Solder surface

Sometimes during soldering, the solder will spread out over a wide area and cause a voltage leak. By comparing OK products with NG products through Sa analysis, it becomes clear that the NG products are rougher. By extending the evaluation area from a line to the entire surface, it allows for even more reliable analysis.

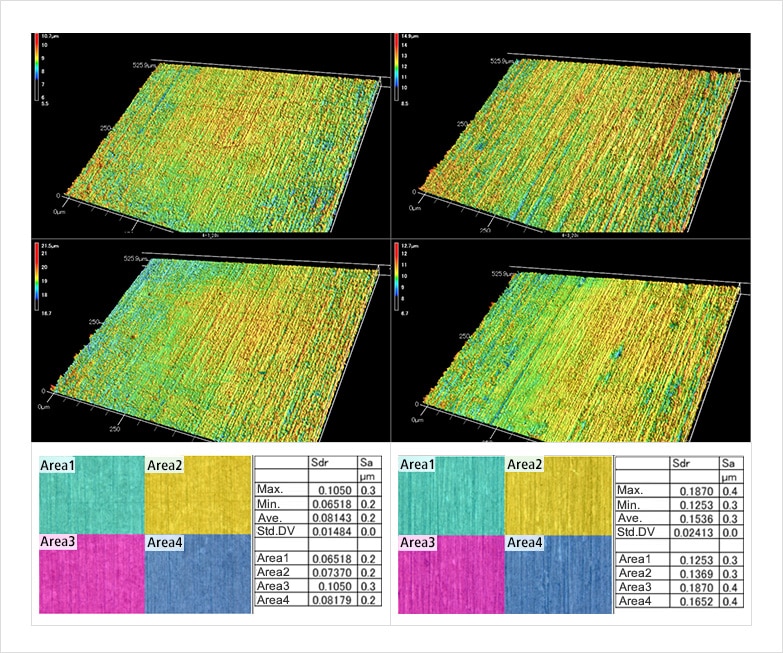

Post-etching evaluation of copper — Sdr (Developed interfacial area ratio) / Sa (Arithmetic mean height)

Copper plating made under varying processing conditions

The roughness of corroded copper-plated surfaces can affect the quality of subsequent processing, such as soldering. Sdr and other analyses are effective at evaluating surface area, while Sa is effective at analyzing the overall roughness.

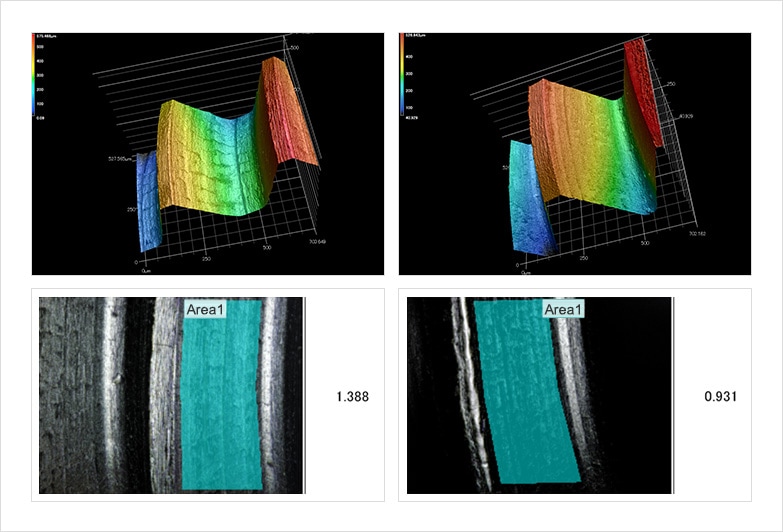

Wear analysis — Sa (Arithmetic mean height)

These images are measured by KEYENCE Optical Profilometer.

Sliding portions of screws

Because materials coming into contact with another part or surface causes friction, Sa anlaysis is used to look at the smoothness of those surfaces. Products that employ different processing methods have smaller Sa values, allowing for improved verification results. This allows for quantification of indices used to maintain quality.