Air Quality Multi-Sensor

MP-F series

Air Quality Multi-Sensor MP-F series

Complete Machine Air Monitoring

- Monitor air flow, temperature, pressure, & humidity

- Easily visualize air quality and consumption

- Built-in shut off valve

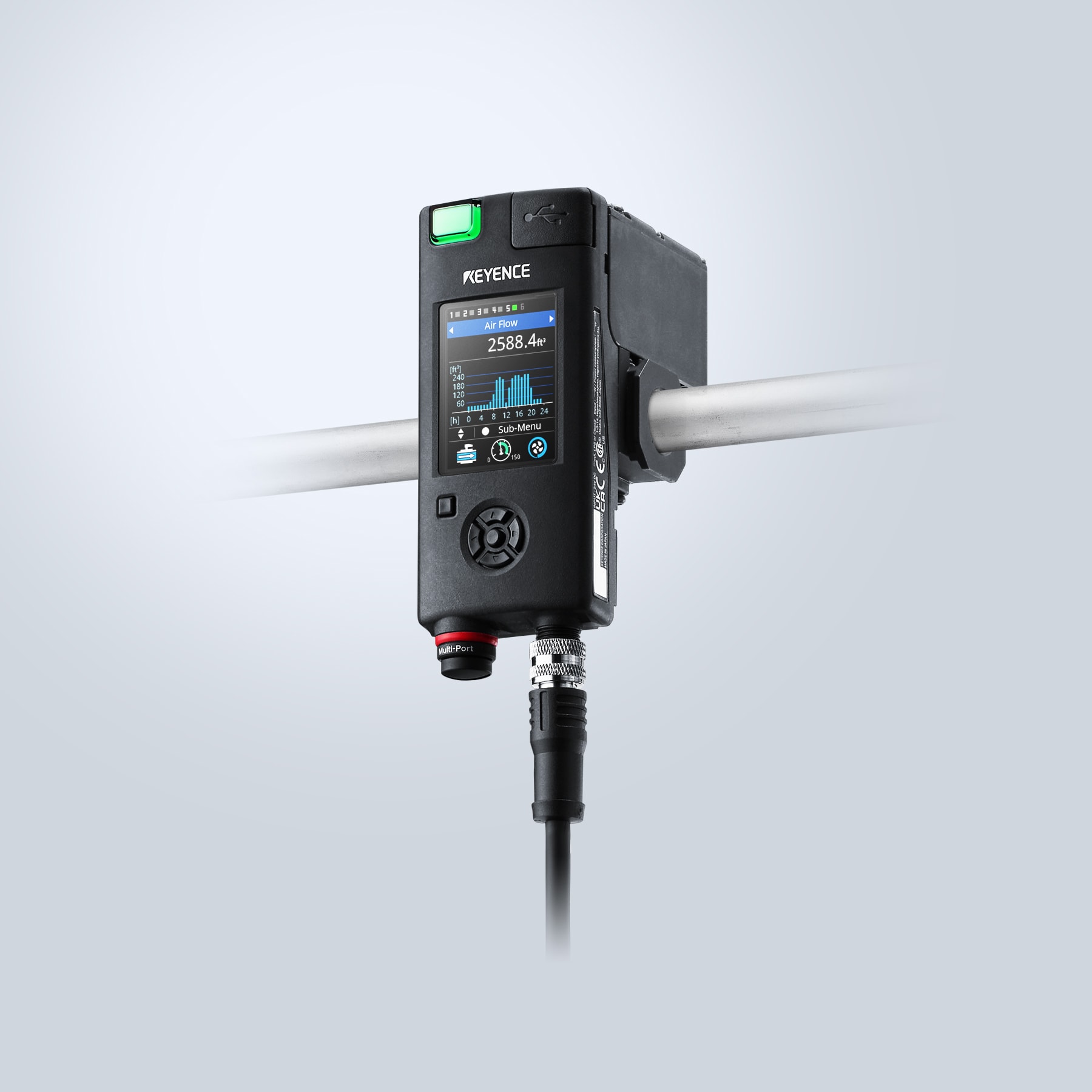

The MP-F Series Air Quality Multi-Sensor simultaneously monitors air flow, pressure, temperature, and humidity, for a complete breakdown of pneumatic machine air quality and consumption. Having an increased understanding of machine air usage allows for more stable machine operation, improved product quality, and ultimately cost savings.The MP-F Series also offers multiple options for data gathering (including the built-in display and dedicated software). Additionally, the unit provides clear visualization of air and electricity consumption. The MP-F Series also includes a built-in shut off valve, which allows users to control their air supply needs when machines are not in use.

Features

All-In-One Monitoring

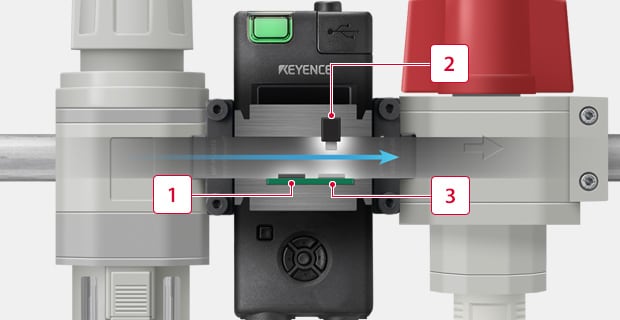

The small body of the MP-F Series contains multiple sensors, allowing for full comprehension of machine air quality and consumption. Better understanding the condition of machine air quality helps ensure the stability of pneumatic equipment, identify abnormalities, and increase lifespan of critical components.

-

1Humidity sensor

-

2Flow/Temperature sensor

-

3Pressure sensor

Easily Visualize Consumption

The MP-F Series offers multiple options to gather data needed to reduce costs and make informed decisions. The easy-to-navigate display offers a clear and complete understanding of all air-related variables, allowing for straightforward air quality and consumption analysis. Long-term data can also be downloaded through the dedicated software with a standard USB cable and laptop.

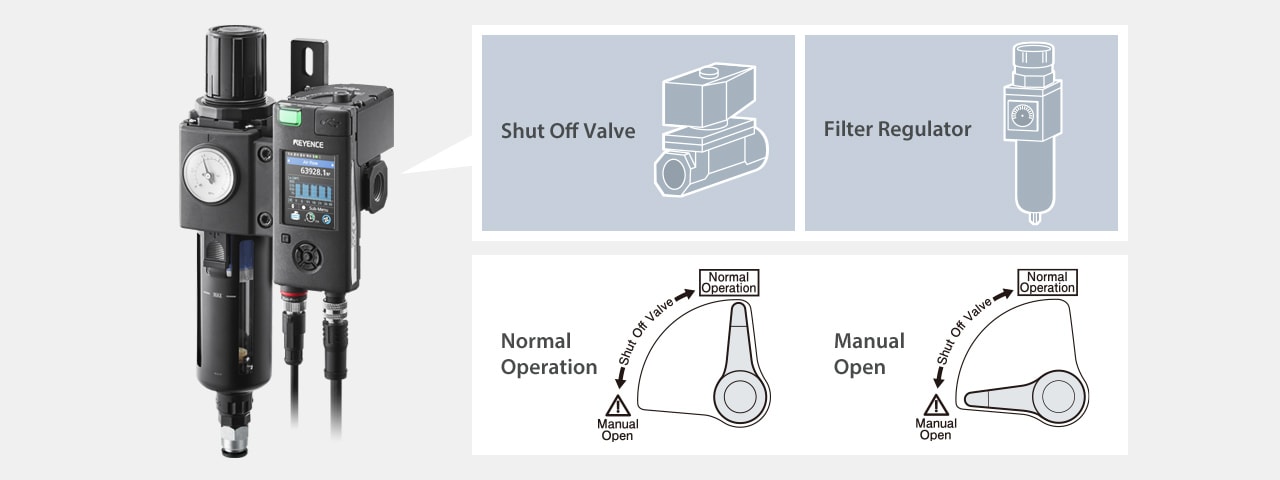

Built-In Shut Off Valve

Cost savings and energy initiatives are of growing importance and the MP-F can make a quick and direct impact. The MP-F Series has a built-in shut off valve allowing customers to automate their air supply needs when machines are down or on break. Simply send the MP-F a signal when the machine is not being used and the valve will shut. There is also a way for this to happen internally within the sensor without the need for additional PLC programming, simply program the sensor to shut off after a certain amount of time of not seeing enough air flow.