High Power Digital Ultrasonic Sensors

FW series

Applications High Power Digital Ultrasonic Sensors FW series

Automotive Industry

Detecting springs during the assembly process

Due to an unstable profile, detection of springs has been unreliable with conventional reflective photoelectric sensors. The FW Series ensures reliable detection without being influenced by background luster.

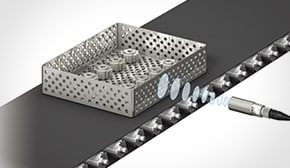

Detecting mesh trays used for quenching the targets

The FW Series ensures reliable detection of targets with metallic luster and small holes. In addition, detection is unaffected by workpieces located on the opposite side of the holes.

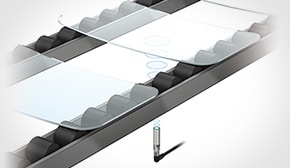

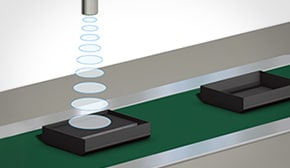

Detecting automotive plate glass

Reliable detection of transparent targets has been difficult with conventional reflective photoelectric sensors. The FW Series ensures reliable detection of transparent targets without being affected by the glass colors.

Checking target removal from a die-cast machine

The FW Series ensures reliable detection of multi-colored targets without being affected by the colors. In addition, detection is unaffected by mold release agents in the environment.

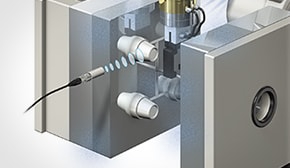

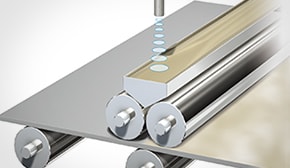

Checking the presence/absence of bolts

The FW Series is used to detect metal targets on metal boards. Detecting only the presence of bolts is possible without being affected by the luster of the metal.

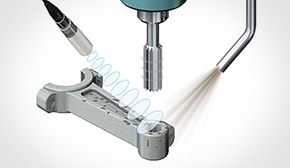

Detecting con-rods

Due to the coolant on the target surface, reliable detection of an atomized area has been difficult with conventional reflective photoelectric sensors. The FW Series ensures reliable detection unaffected by the coolant on the target surface.

Detecting black-colored cushioning material on black resin

Detection of black-colored targets has been difficult with conventional reflective photoelectric sensors. The FW Series ensures reliable height differentiation without being affected by color.

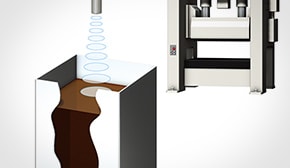

Detecting the liquid level of hydraulic fluid for a press

Dirty oil has been difficult to detect with conventional contact liquid level sensors. The FW Series enables non-contact detection reducing the need for costly maintenance services.

Detecting the fluid level of adhesive on a roll coater

Detection of adhesive with high viscosity has been difficult with conventional contact liquid level sensors. The FW Series enables non-contact detection. In addition, outputs of upper and lower limits can be performed separately.

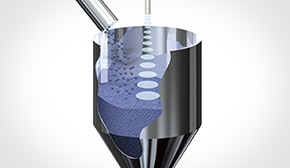

Detecting remaining pellet quantity in a hopper

Due to shape and color variations of pellets, detection has been unstable with conventional reflective photoelectric sensors. The FW Series ensures reliable detection regardless of pellet color or shape.

Food, Chemical, and Cosmetics Industries

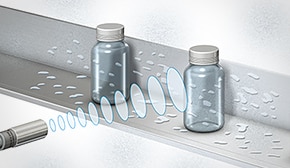

Detecting transparent bottles in the cleaning process

The FW Series ensures reliable detection of transparent targets with a rounded shape. In addition, detection is unaffected by an environment where water splashes on the target surface.

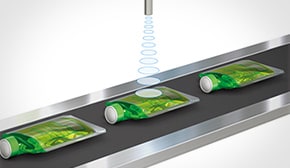

Detecting vinyl packages on a conveyer

Due to the transparency of the target and the unstable surface profile, detection has been difficult with photoelectric sensors. The FW Series can reliable detect targets with a rippled surface profile.

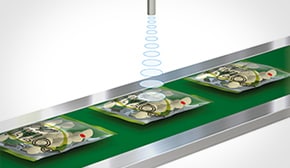

Detecting confectionery packaging on a conveyer

Depending on the condition of the contents, stable detection of transparent confectionery packaging has been difficult with conventional photoelectric sensors. The FW Series reliably detects only the outside transparent package without being affected by the contents.

Detecting transparent lids of containers

The FW Series ensures reliable detection even if the target surface is rippled. In addition, detection is not affected by the inner contents when covered with a transparent lid.

Differentiating the presence / absence of product packaging and product varieties

The FW Series is capable of differentiating only the height without being affected by the color or pattern of the targets. In addition, it is capable of differentiating product variety by using two outputs.

Detecting the presence / absence of contents in containers

Pasta or targets with an uneven surface profile can be detected reliably. In addition, detection is not affected by steam from fresh-cooked targets.

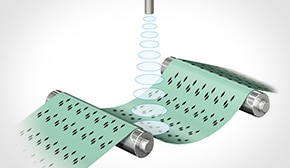

Detecting slack in films

Reliable detection is ensured regardless of surface color, pattern, and luster. In addition, upper and lower limits can be output separately.

Detecting the level of chocolate

Since the targets are food products, contact liquid level sensors cannot be used. In addition, detection with photoelectric sensors is adversely affected by the target color and luster. The FW Series ensures reliable detection regardless of target color and luster.

Semiconductor/ Electronics/ Electrical Industry

Detecting wafers in the cleansing process

Reliable detection of sweating wafers is ensured even in a vaporous atmosphere immediately after the slicing process.

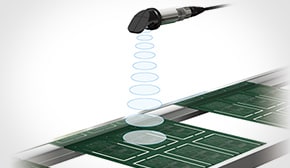

Detecting slit substrates in the transfer process

Due to the colors and slits of the substrate, instability and chattering of outputs have been inevitable with conventional photoelectric sensors. The FW Series ensures reliable detection unaffected by colors and small slits.

Controlling web tension

Due to transparency and surface irregularities, detection with photoelectric sensors has been difficult. The FW Series ensures reliable detection unaffected by projections and depressions. In addition, the two outputs can be used for making outputs of upper and lower limits separately.

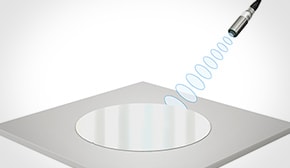

Detecting wafers from an angle

Detection has been difficult because of the minute height difference between the thin wafer and background. The FW Series ensures reliable detection by applying ultrasonic waves from an angle to cause slight reflections from the edge.

Detecting wafers in a magazine rack

The FW Series is used to detect the remaining wafers. Detection with reflective-type sensors has been difficult because the light was absorbed by the surface film of the wafers. The FW Series is not affected by surface films or glossy backgrounds.

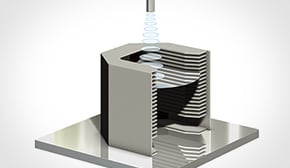

Controlling the fluid level of a cleaning solution

The FW Series is used for controlling the liquid level. The two outputs can be used for making outputs of upper and lower limits separately. In addition, the special liquid level detection mode enables various controls with simple setup.

![NR-X Data Logger / Data Acquisition Direct connection to other KEYENCE products [Click Here to Learn More!]](/Images/nr-x_series_300_300_01_2089589.jpg)