LED Lighting

CA-D series

LED Lighting CA-D series

LED Lighting

Vision system peripheral equipment

CONTACT YOUR NEAREST OFFICE FOR RELEASE STATUS

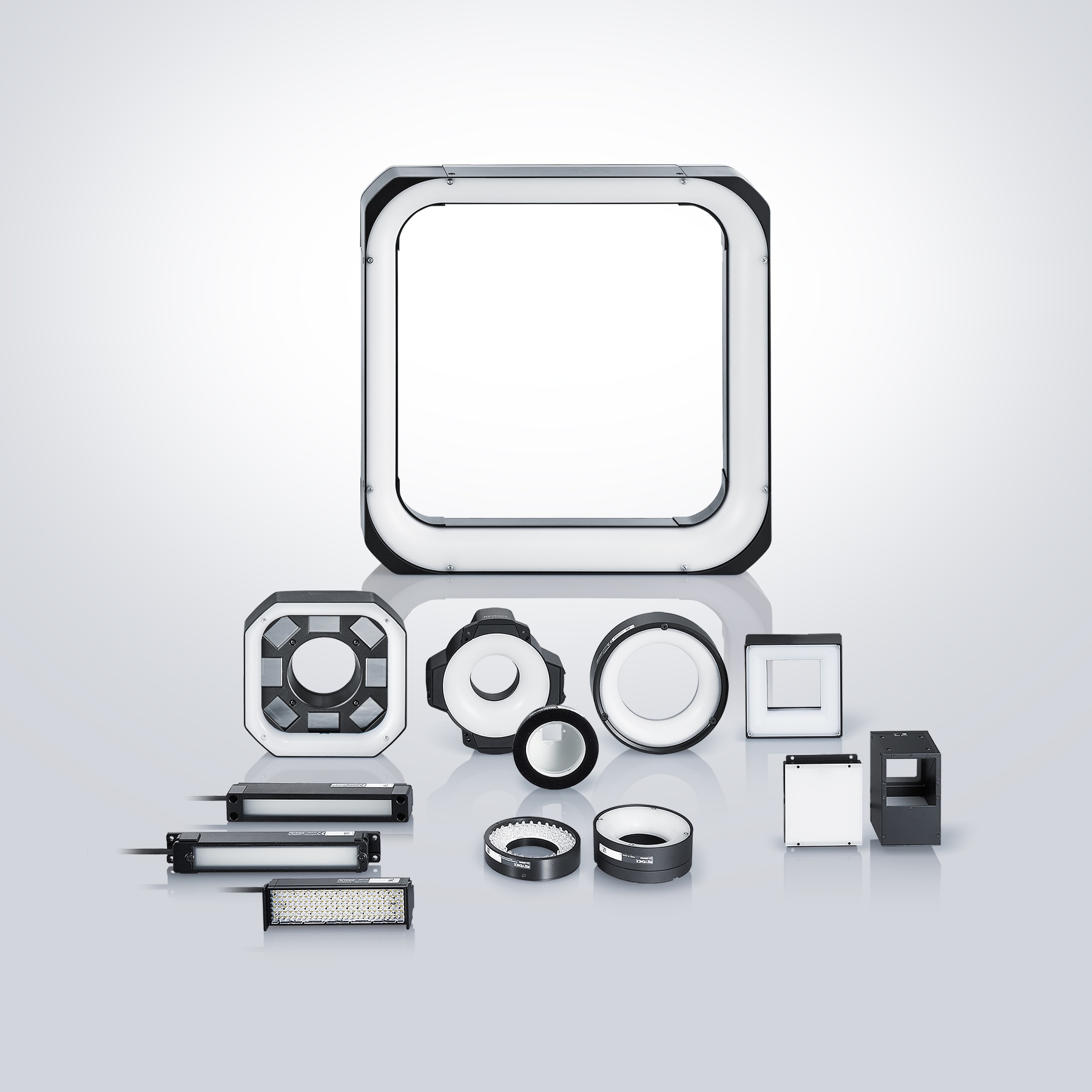

The KEYENCE LED lighting series offers a wide selection of lighting that is directly connected and controlled by KEYENCE vision systems to obtain consistent target illumination and highlight desired features. This lineup spans from traditional machine vision lighting (available in white, red, and blue) to innovative, high performance lighting techniques. The high performance lighting unlocks inspections that were previously impossible or unreliable. LumiTrax™ lighting enables surface appearance inspections with no influence from background glare and patterns. Multi-Spectrum lighting combines 8 different colors of light to differentiate subtle differences and defects. Pattern Projection lighting transforms a 2D camera into a simultaneous 2D/3D inspection system with its addition of height data.

A Lineup of Lights for a Wide Variety of Inspections

KEYENCE's rich lineup of lights can support all types of workpieces.

These lights provide strong support for stable detection for image processing.