- Home

- Solutions

- Case Studies

- Analyzing Metal Polymer Bearings for GGB

Analyzing Metal Polymer Bearings for GGB

Analyzing Metal Polymer Bearings

As the world leader in plain bearings, GGB continually strives to offer the best solutions for its customers. To support its product development, its R&D departments in France, Germany and the US have each invested in a VHX-1000 to obtain better 3D visualizations of their product under high magnification.

“The KEYENCE VHX-1000 digital microscope enables us to do things we were unable to do before: The quality of the high resolution 3D images, for example, makes it possible for us to study the interaction of sliding surfaces in greater detail. In particular, it allows us to examine wear marks, transfer films and bearing damage after testing in great detail. This enables us to better understand the behavior of our products and help optimize our product development” explains Derek Marsella, GGB’s Senior Manager, Annecy Technology Group.

GGB is the world’s leading manufacturer of high-performance, self-lubricating and pre-lubricated plain bearings, with more than 1,000 employees globally, including production facilities the U.S., Germany, France, Brazil, Slovakia and China. Many of GGB’s polymer plain bearings are able to operate effectively under extreme conditions, sometimes even more effectively than conventional bearings with rolling elements. Due to the specific material design that relies on a metal backing with low friction, self-lubricating polymer sliding surface, these bearings are the ideal choice in environments of high load, limited lubrication with space constraints. Typical applications include pumps, compressors, off-highway equipment, machinery and steel processing and various automotive components.

The VHX-1000, a revolutionary digital microscope that is adding value to R&D departments

Despite its compact size, the camera includes an actuator to enable the use of pixel shift technology, achieving observation with super high resolution of up to 54 million pixels. A progressive scan method allows textured surfaces and colors to be reproduced similar to observation with the naked eye. The VHX-1000 provides a depth-of-field at least 20 times larger than optical microscopes. Thus, the VHX-1000 can accurately observe a target (even with a large height difference) that could not be seen in focus with conventional microscopes. Furthermore, the number of steps required for observation including focus adjustment can be reduced considerably. VHX-1000 enables users to capture high-resolution images over a large field-of-view. Unlike conventional methods, which perform stitching after capturing all images in external software, KEYENCE has developed a completely new image stitching algorithm. When the user moves to a different location on the part using a manual stage, the area is stitched together in real time. The field-of-view can be expanded from a normal field (1600 x 1200 pixels) up to 10000 x 10000 pixels, without any loss in resolution.

User-friendly tools facilitate communication

“One other key advantage of the VHX-1000 is that it is portable and really user-friendly” adds Derek Marsella. “If necessary, we are able to visit our customers with this portable unit and inspect bearings in their factory. The high resolution images can be seen directly on the screen helping us to better communicate and explain our findings. This unit enables us to offer a higher level of service to our customers”.

“In our business, clear 3D visualization of the bearing surface in order to understand and define its state and behavior is very important”. The VHX-1000 enables the creation of a high-quality composite image instantly by turning the focus knob and proceeding directly to the 3D display mode. The D.F.D method (which stands for depth from defocus) enables the capture of 3D depth data through analysis of defocus of 2D images. The VHX-1000 series enables depth composition and 3D image display by using fewer sample images than conventional microscopes. This method eliminates the need to load images at all focal positions, resulting in analysis efficiency improvement.

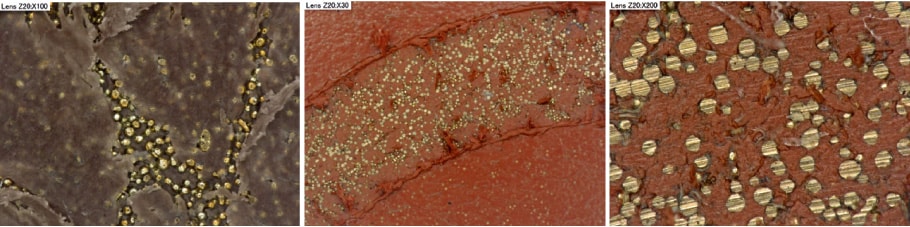

In this view, we can observe bronze particles that have become exposed due to fatigue or wear damage during testing. The bronze particles are part of the porous bronze interlayer in GGB’s products that provides a mechanism for adhering the polymer sliding layer to the metal backing. GGB’s products are composed of 3 layers: metal backing providing strength, bronze interlayer providing a mechanical key, and a polymer sliding layer.

-

“The VHX microscope was first selected by our German Technical Centre. We were so impressed by its capability and value that we chose to standardize this tool across all our R&D facilities throughout the world”, concludes Derek Marsella.

-

VHX-5000 series

With a depth-of-field and resolution that are unmatched by conventional optical microscopes, users can take imaging to a whole new level.

APPLICABLE PRODUCT CATALOG

- PLEASE

CONTACT US