Digital Microscopes

Observation and Measurement of Electric Vehicle (EV) Components Using Digital Microscopes

Electric vehicles (EVs), which emit no greenhouse gases, are drawing attention as part of creating a carbon neutral society. This section introduces observation and measurement examples of in-vehicle motors and parts related to engine control units (ECUs) or invertors, which are key parts of EVs, using digital microscopes.

Characteristics of EVs

- Eco-friendly because EVs do not emit greenhouse gases.

- Low fuel (electricity) costs for travel distances

- High acceleration performance

- Small number of parts

- Easy maintenance

Get detailed information on our products by downloading our catalog.

View Catalog

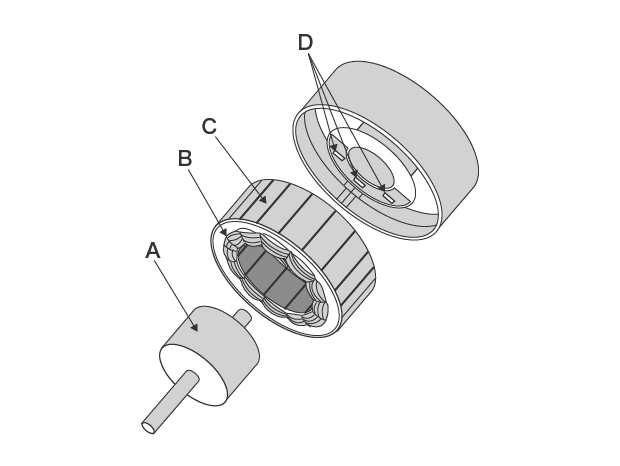

In-vehicle Motor Structure

A: Rotor B: Stator coil C: Stator

D: Rotor rotation position sensors

Brushless alternating-current (AC) motors are mounted on EVs. There is no brush, which reduces noise and simplifies maintenance.

- Rotor

This is an output shaft that drives wheels via a reducer. Permanent magnets are used. - Stator

This part generates force for rotating a rotor. It passes electricity through the stator coil according to the rotor rotation. - Rotor rotation position sensor

This sensor detects the rotor rotation position to pass alternating current that corresponds to the rotor rotation speed through the stator coil.

We’re here to provide you with more details.

Reach out today!

Types of Permanent Magnets

- Ferrite magnet

Ferrite magnets are cheap and easy to form. They are used for in-vehicle DC motors. - Neodymium magnet

Neodymium magnets have magnetic energy that is at least 10 times that of ferrite magnets and are used for EV driving motors.

Neodymium magnets are expensive because rare earths are used in their construction. Neodymium magnets are hard but have the drawback that they are sensitive to heat and prone to rust.

We’re here to provide you with more details.

Reach out today!

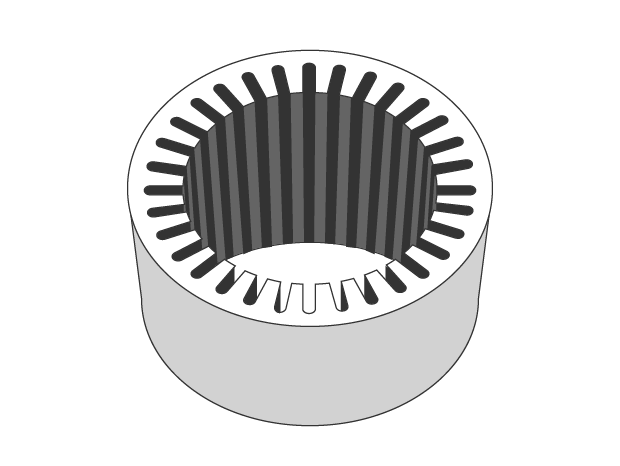

Stator Structure

A stator has layers of electromagnetic steel sheets each with a thickness of 0.3 to 0.5 mm (0.012″ to 0.020″).

Electromagnetic steel sheets made from soft magnetic materials are used because magnetic poles need to be reversed instantaneously. The thinner the electromagnetic steel sheets are, the more eddy current can be suppressed in the electromagnetic steel sheets. (Smaller energy losses) Additionally, eddy current losses can be reduced by coating sheet surfaces to insulate them from each other.

We’re here to provide you with more details.

Reach out today!

ECUs and Inverters

ECUs and inverters used for EVs have the following characteristics.

- ECU

ECUs control the electricity that passes through stator coils by calculating the optimal number of rotations and torque. The number of rotations is controlled using the frequency and the torque is controlled using the current. - Inverter

Inverters are components that convert direct current supplied from batteries into alternating current. Inverters not only convert direct current into alternating current but also adjust the frequency and the amount of current during conversion to control the number of rotations and torque of motors.

We’re here to provide you with more details.

Reach out today!

Observation and Measurement of EV Components Using Digital Microscopes

These are the latest examples of observation and measurement of EV components using KEYENCE’s VHX Series 4K Digital Microscope.

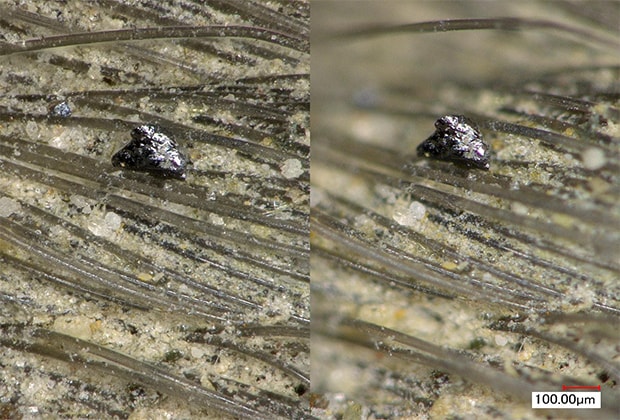

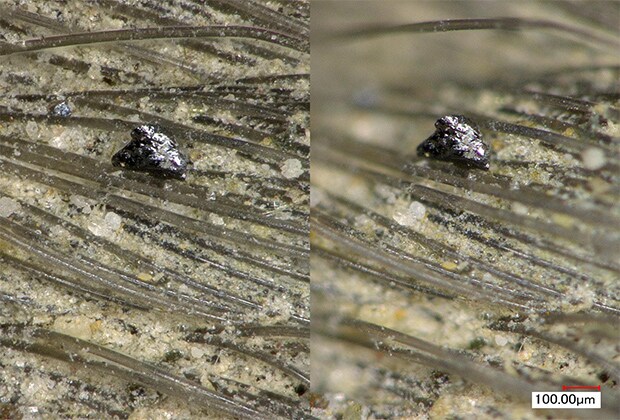

Foreign material observation on a motor surface

VH-Z20, 200×, ring illumination, left: depth composition image, right: normal image

Using the depth composition function allows for observation with images where the entire screen is in focus, even at high magnifications.

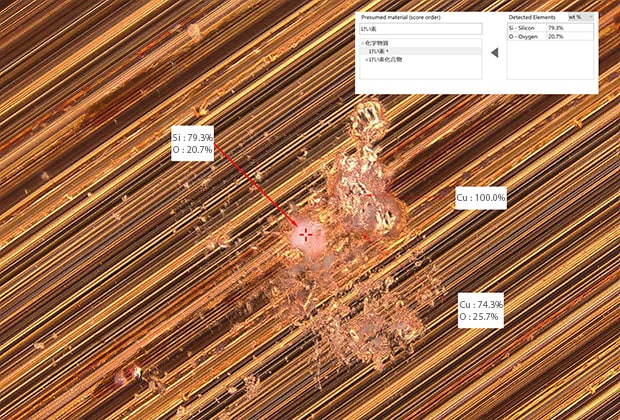

Elemental analysis of foreign particles on a power card

EA-300, 300×, ring illumination

Quick analysis can be performed on-site to determine whether observed targets are foreign particles in the container or dust.

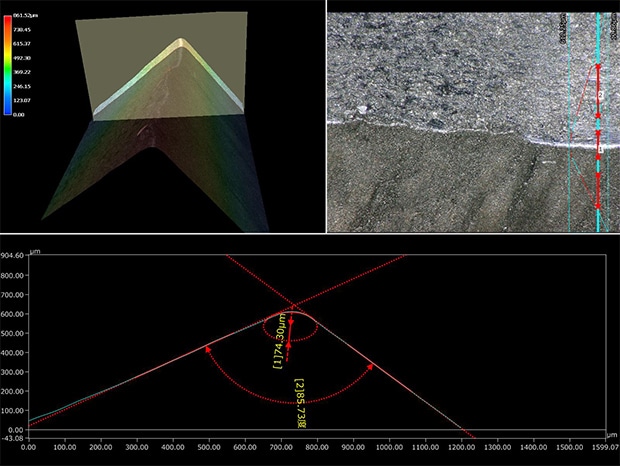

3D measurement of a bonded magnet corner radius

VH-Z20, 200×, ring illumination

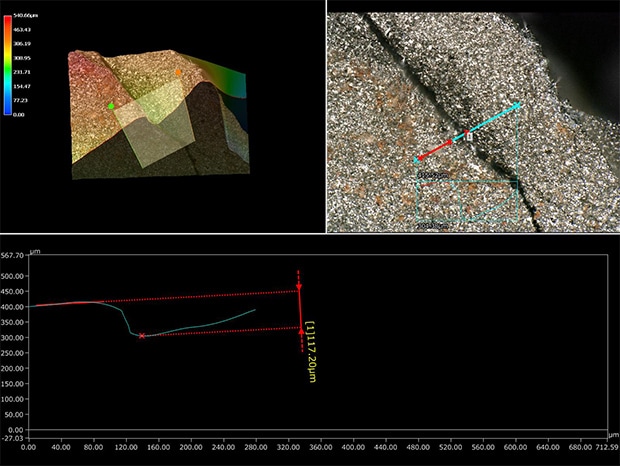

3D profile measurement of a neodymium magnet fracture surface

ZS-200, 500×, ring illumination

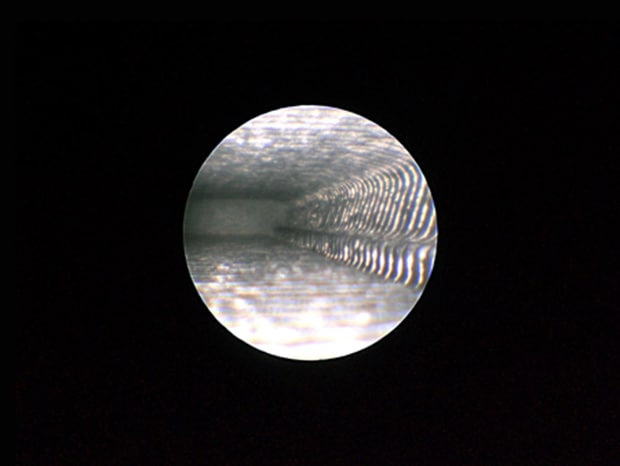

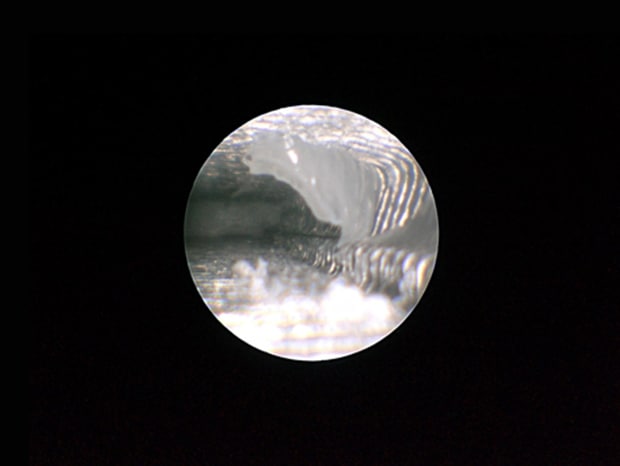

Observation of the adhesion of a rotor adhesive

Using a borescope allows for observation of the inside of a motor through a 2 mm (0.079″) gap.

ø1.8-mm (0.071″) borescope, without adhesive

With adhesive

Observation of a crimped part on a harness

Using the glare removal function suppresses the influence of reflection.

VH-Z20, 100×, ring illumination, normal image

Image after glare removal

VHX-E20 40×, upper: Optical Shadow Effect mode image, lower: normal image

Optical Shadow Effect mode can visualize surface irregularities.

Observation of peeled plates on an electromagnetic steel sheet

Get detailed information on our products by downloading our catalog.

View Catalog