Digital Microscopes

Observation and Measurement of Textured Surfaces Using Digital Microscopes

Surface texturing is a process that gives textures to metal and plastic surfaces. Texturing not only makes products look high-class but also adds functions such as prevention of reflection and slipping. This section introduces observation and measurement examples of textured surfaces using digital microscopes.

What is a Texture?

A texture is a wrinkle pattern formed on a metal or plastic surface. Texturing can give various appearances, such as wood texture, leather texture, matte texture, and geometric patterns, in addition to simple irregular surface patterns.

Get detailed information on our products by downloading our catalog.

View Catalog

Classifications and Purposes of Texturing

Design improvement

- A high-class appearance is added.

- Molding defects, such as sink marks and weld lines, are made less noticeable.

- Dirt and flaws are made less noticeable.

Improvement of functionality

- Light is diffused, which prevents gloss.

- Antiskid effects are added.

- Close contact is prevented.

- Moisture retention and water repellent effects are improved.

We’re here to provide you with more details.

Reach out today!

Texturing Types

Metal surfaces are either directly textured, or metal molds are textured and that texture is transferred to products. Typical methods are introduced below.

- Etching

Surface irregularities are formed by masking areas that should not be processed and applying an etchant (mordant) to areas to be processed. This method is typically used to form leather textures. - Sandblasting

Fine abrasives are sprayed into metal mold cavities to form surface irregularities. The size of surface irregularities is controlled by changing the size of the abrasive and level of blasting force. This method is typically used to form matte textures. - Cutting

Metal molds are cut with small end mills to form surface irregularities. - Laser processing

Metal mold surfaces are engraved with a laser to form surface irregularities. Complex geometric patterns can be formed.

We’re here to provide you with more details.

Reach out today!

Observation and Measurement Examples of Textured Surfaces Using Digital Microscopes

These are the latest examples of observation and measurement of textured surfaces using KEYENCE’s VHX Series 4K Digital Microscope.

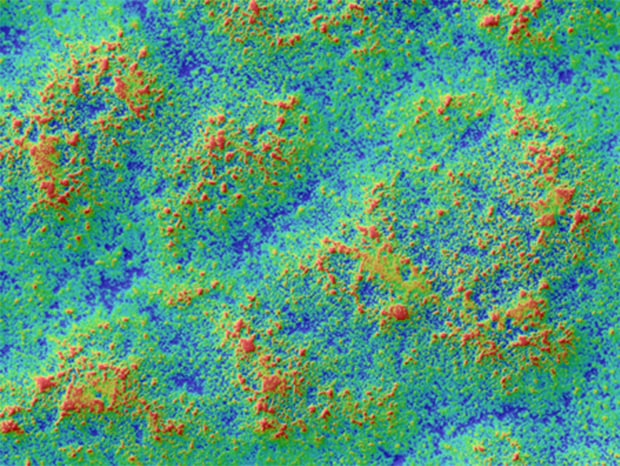

Observation of steering wheel texture

VHX-E100, 100×, ring illumination

Normal image

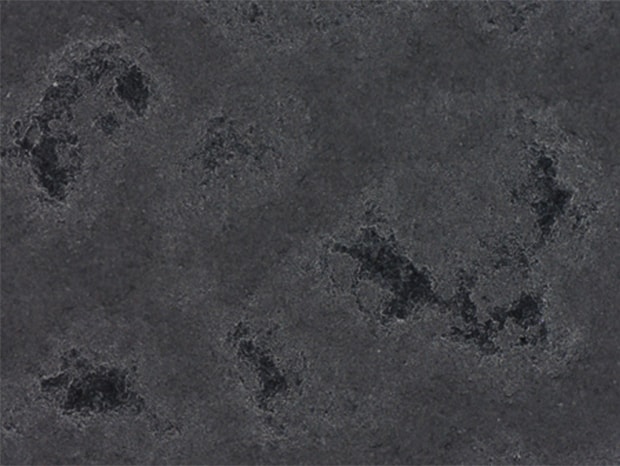

Optical Shadow Effect Mode image

Optical Shadow Effect Mode can be used to visualize irregularities.

Optical Shadow Effect Mode

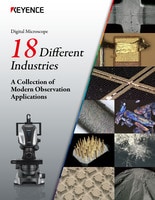

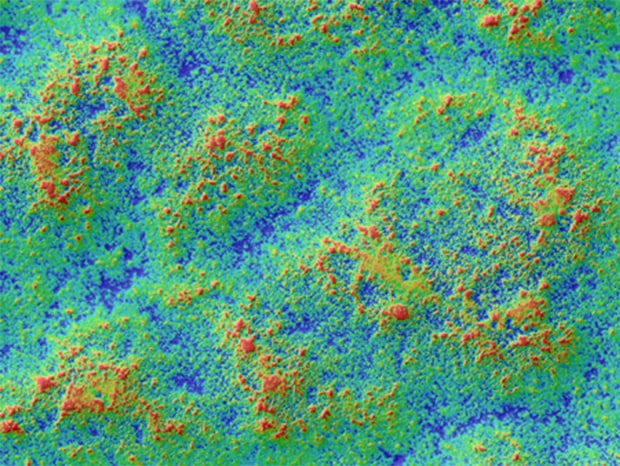

Color Map image

Height differences can be displayed in different colors on Color Map images.

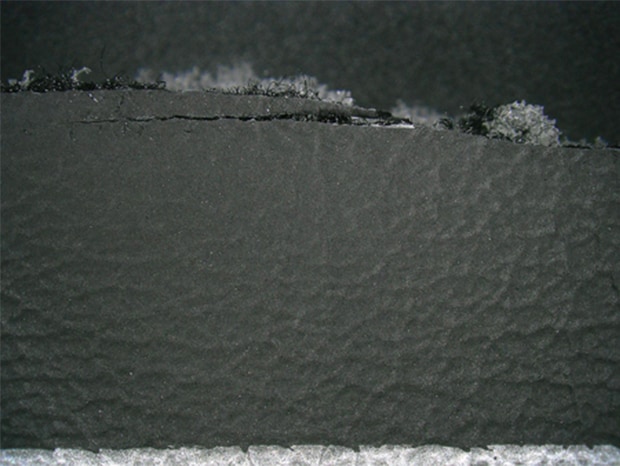

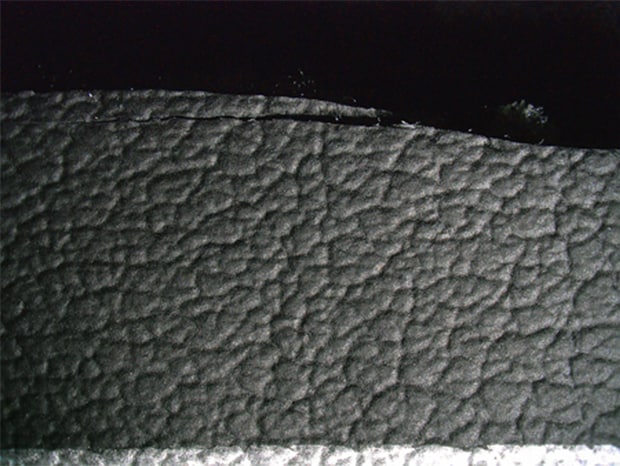

Observation of car seat surface texture

ZS-20, 20×, ring illumination + multi-lighting

Normal image

Multi-lighting image

The optimal lighting conditions can be selected using the multi-lighting function.

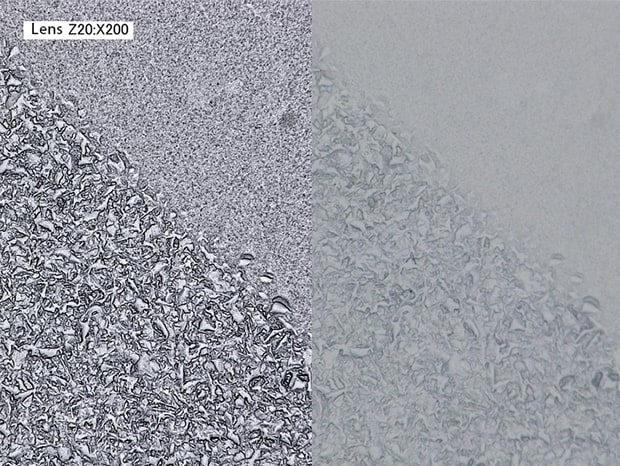

VH-Z20, 200×, ring illumination + HDR

Observation of an instrument panel texture (white)

Left: HDR + Depth composition image Right: Normal image

Even white textures can be clearly observed using the HDR function and depth composition.

VH-Z20, 200×, ring illumination

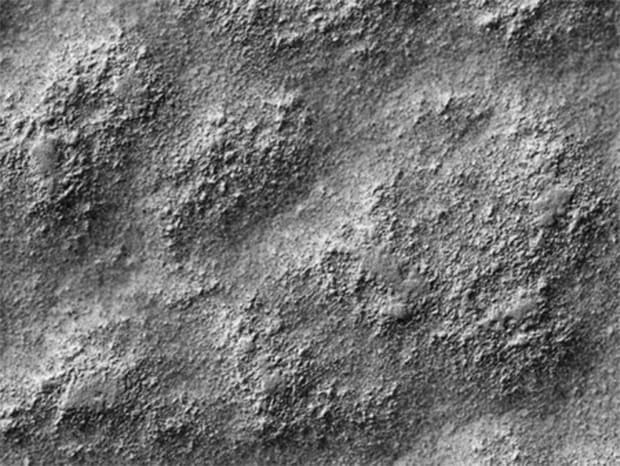

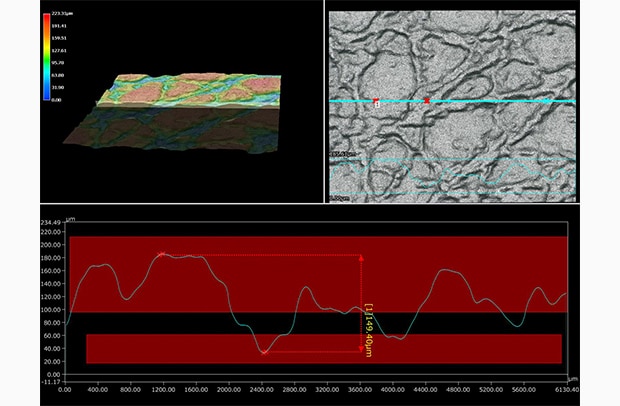

3D profile measurement of a textured surface

Texture shapes can be analyzed with 3D profile measurement.

VH-Z20, 200×, ring illumination

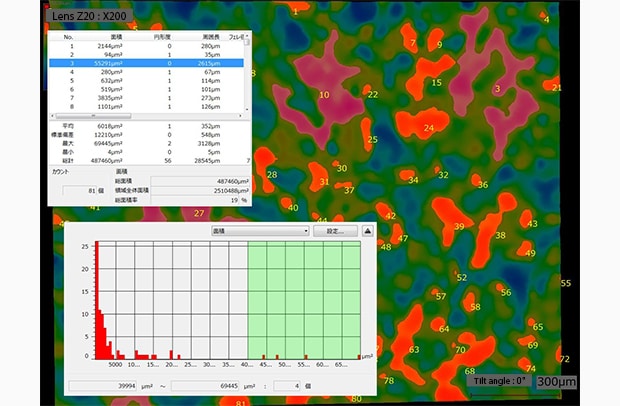

Automatic area measurement of a textured surface using a 3D image

3D images in which height differences are displayed in different colors can be analyzed using the automatic area measurement function, which allows for measurement of the height distribution ratio. Texture distribution used to be unmeasurable, but now it is possible to analyze prototypes and control quality.

Get detailed information on our products by downloading our catalog.

View Catalog