UV Laser Coding and Marking on Beverage Packaging

In order to guarantee accuracy and dependability, UV laser coding in beverage packing has become a necessity. The technology is ideal for permanently marking items like powdered drink stick packs, bags, coffee/tea, and coding labels on bottles.

Beverage Packaging Challenges Solved by KEYENCE UV Laser Coder Technology

Beverage packaging presents unique challenges—moisture, temperature shifts, and the need for durable, high-contrast codes on materials like shrink sleeves and pouches. However, high-speed production lines, moisture, condensation, and temperature fluctuations create significant challenges for conventional marking methods like thermal transfer (TTO) printers. Ink-based coders, like thermal ribbon (TTO), often struggle with smudging, fading, or poor adhesion on slippery or powdery surfaces, leading to rework, waste, and potential compliance issues. Regular printhead cleaning, ink replacement, and maintenance slow down operations and raise expenses. UV laser coding and marking in beverage packaging help overcome these difficulties.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

We’re here to provide you with more details.

Reach out today!

Why Choose the FP-1000 Series for Beverage Packaging Marking Needs?

When it comes to beverage packing laser marking needs, precision, and sustainability are non-negotiable. The FP-1000 Series laser coder is a preferred choice by packaging facilities due to its:

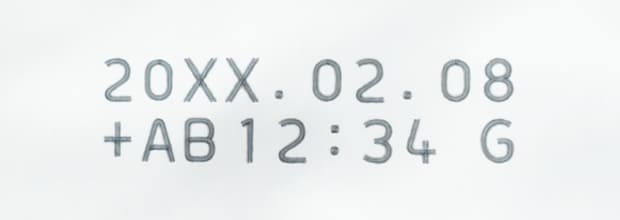

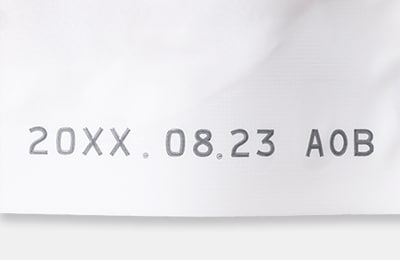

Precision and Clarity

Achieve sharp, permanent codes on powdered beverage stick packs, bottle sleeves, and more. UV lasers mark straight through water, dust, powder, and even oil without smudging or fading.

Marking example (granule package)

Marking example (retort food pouch)

Marking example (toothpaste tube)

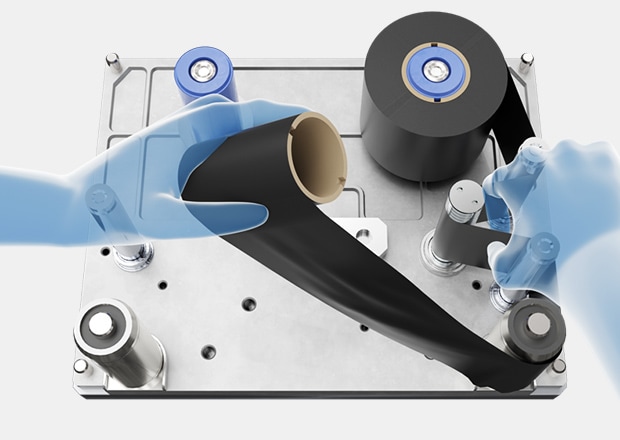

Cost Efficiency

With no consumables required, the FP-1000 Series reduces operational costs and minimizes downtime.

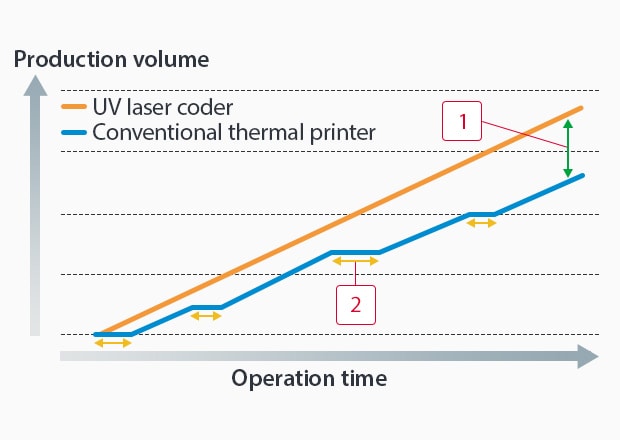

Minimize Downtime

Improve Overall Equipment Effectiveness (OEE) as downtime is reduced or eliminated.

No ink ribbon costs

No head replacement costs

-

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Reduce Operator Errors

With an intuitive touch panel interface and user-friendly features, training and operations are simplified, and errors are reduced.

No periodic parts replacement required

No periodic maintenance/inspection required

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in the Beverage Packaging Industry

Can UV Laser Coders Ensure Permanent Marking on Beverage Packaging Despite Harsh Manufacturing Environments?

Yes, the FP-1000 Series marks internal layers of the film sleeve or stick pack sachet directly. This is not impacted by water or powder on the label surface or subsequent heat, abrasion, and moisture . Because of these characteristics, codes stay intact for the duration of the product's lifecycle, making it perfect for beverage packaging applications.

How Does UV Laser Marking Impact Production Speed and Reduce Downtime in Beverage Packaging Lines?

UV laser coding in beverage packaging boosts production throughput with high-speed, precise coding while reducing downtime by eliminating consumables and maintenance. No more bottle necks or line stoppages for inefficient ribbon printers.

What Are the Cost-Saving Benefits of Using UV Laser Coders for Beverage Packaging, Especially with Regard to Consumables?

The FP-1000 Series significantly reduces operating costs by doing away with consumables like ink or ribbons. Additionally, fewer moving parts mean reduced maintenance expenses. Each new mark made by the FP-1000 Series reduces the cost per mark for decades to come.

How Does UV Laser Coding Help Maintain Brand Consistency and Prevent Counterfeit Products in the Beverage Industry?

To improve traceability and discourage counterfeiting, UV laser coders generate accurate, readable, and permanent codes.

How Does UV Laser Coding Enhance the Readability and Legibility of Codes on Beverage Packaging?

The FP-1000 Series produces clear and crisp codes on a variety of surfaces, including reflective and transparent beverage packages, regardless of surface moisture, powder, or abrasions.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)