UV Laser Coding on Candy and Confectionery Packaging

The FP-1000 Series UV laser coder offers cutting-edge technology for printing and coding on candy packaging, seamlessly replacing traditional thermal transfer overprinters (TTO). Designed to work without altering packaging films or machines, the technology provides precise, high-quality codes while eliminating waste, costs, parts, downtime, and consumables like ribbons.

UV Laser Coding and Marking on Candy Products

The FP-1000 Series UV laser coder stands out on candy and confectionery packaging materials, working well with multi-layer films, foils, paper-based materials, and laminated packaging.

- Chocolate and chocolate bars

- Candy wrappers and hard candies

- Gummies and jellies

- Chewing gum packaging

- Cookies, cakes, and donuts

- Other baked goods and sweet-packaged treats and desserts

We’re here to provide you with more details.

Reach out today!

Candy Packaging Challenges Solved by KEYENCE UV Laser Coder Technology

High Consumable Costs

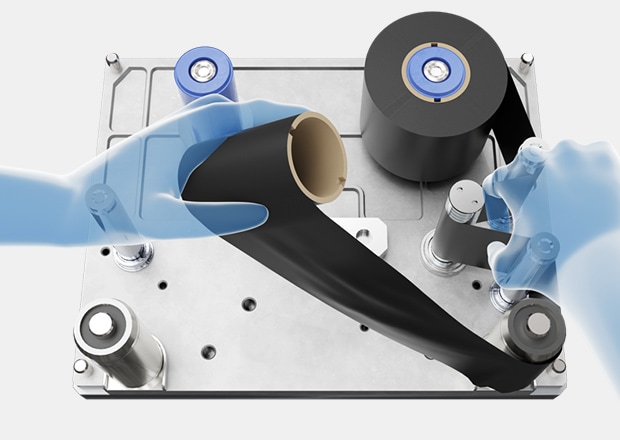

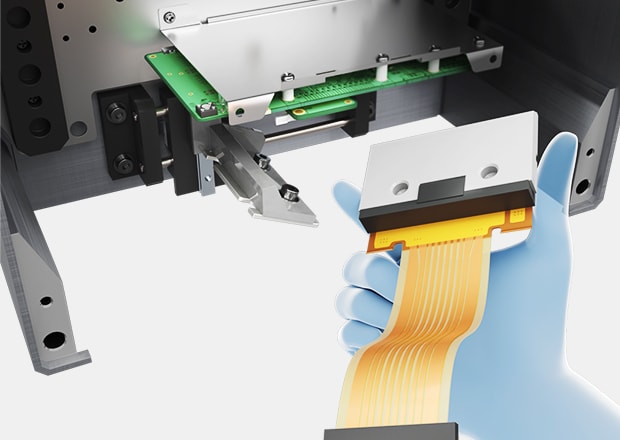

Marking methods like thermal transfer overprinting (TTO) require consumables and parts like ribbons and print heads, leading to increased costs and downtime. The FP-1000 Series uses light-based marking, completely eliminating the need for consumables.

No ink ribbon costs

No head replacement costs

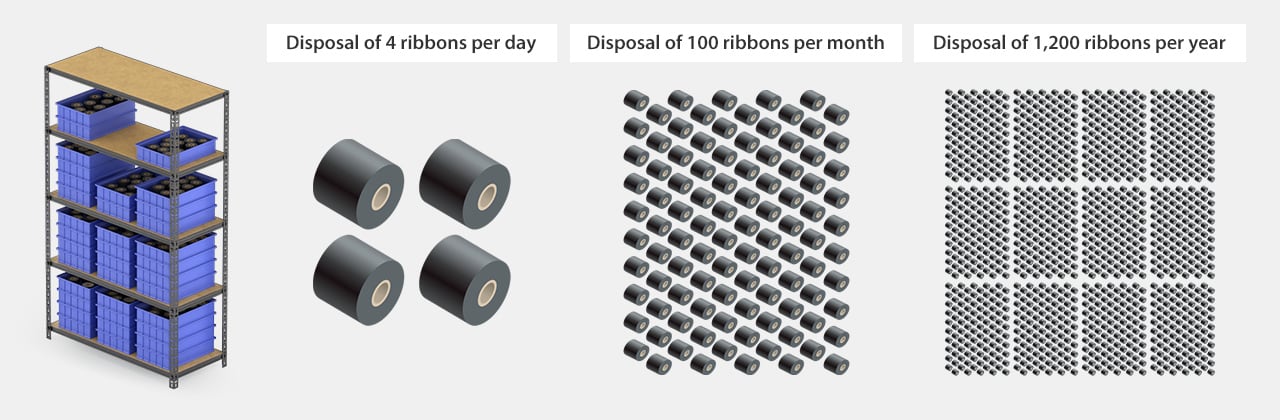

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

No periodic parts replacement required

No periodic maintenance/inspection required

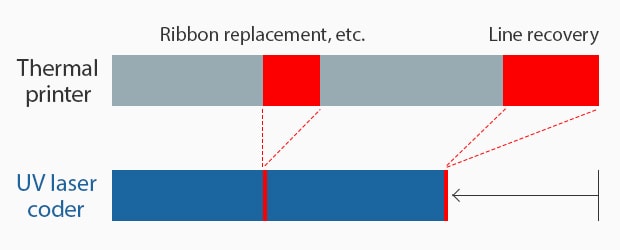

Production Downtime

Frequent production stoppages and costly downtime are required with TTO to replace ink ribbons and other parts as they wear out or break. The FP-1000 Series' non-contact, consumable-free technology eliminates downtime and maximizes operational efficiency.

-

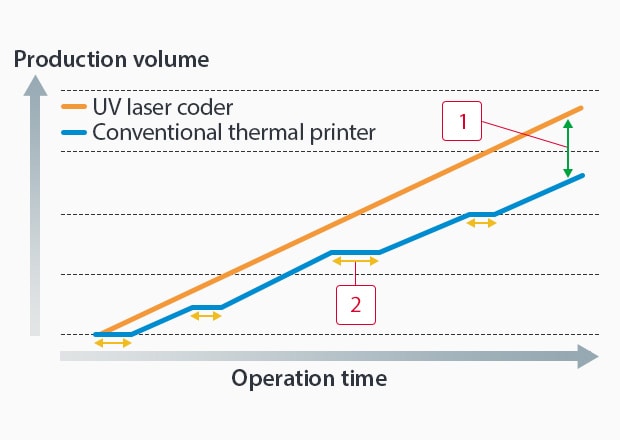

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Mark Permanence

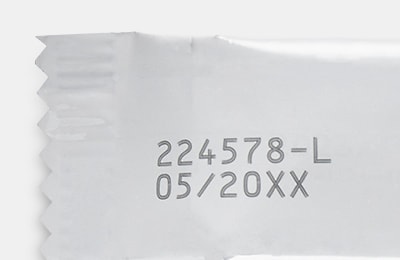

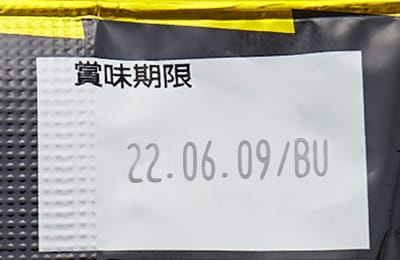

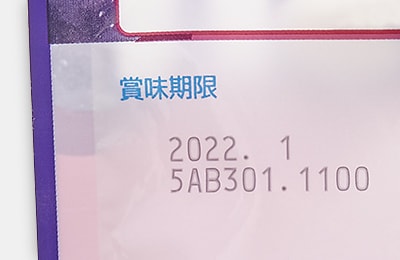

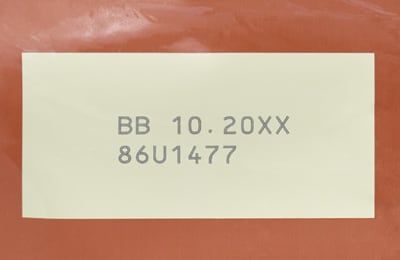

One of the major issues coding in candy industry packaging is ink smearing, smudging, fading, or becoming illegible. When codes are missing or unreadable, it can lead to regulatory issues such as expensive recalls and fines. Accurate labeling is vital for compliance and traceability throughout the supply chain. The FP-1000 Series solves this, ensuring high-contrast, long-lasting marks.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

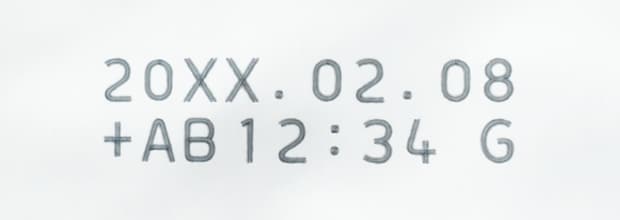

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Operating energy for packaging line equipment (packaging machine, compressor, air conditioner, lighting, etc.) can be significantly reduced.

Environmental Concerns

Traditional coding methods often produce waste. The FP-1000 Series' eco-friendly, consumable-free operation helps businesses reduce their environmental footprint.

Why Choose the FP-1000 Series for Candy Marking Needs?

The FP-1000 Series offers unmatched precision, high-speed performance, and reliable, non-contact UV laser marking. Downtime and consumable costs can be eliminated while ensuring eco-friendly, permanent marks. Seamlessly integrate it into your production line for all candy industry laser marking needs. Contact us today to discover how the FP-1000 Series can enhance and simplify your production, all while lowering operational costs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Candy and Confectionery Packaging

What Are the Benefits of UV Laser Coding in the Candy and Confectionery Industry?

UV laser coding in the candy industry and confectioneries offers clean, permanent marks, reduces consumable costs, eliminates ink fading, and ensures high-quality codes on various packaging materials.

How Does UV Laser Coding and Marking Improve Candy Production?

Marking with UV lasers boosts production efficiency by removing consumable needs, reducing downtime, and providing high-speed, reliable coding on packaging without interruptions.

What Are Common FP-1000 Series UV Laser Coder Applications in the Candy and Confectionery Industry?

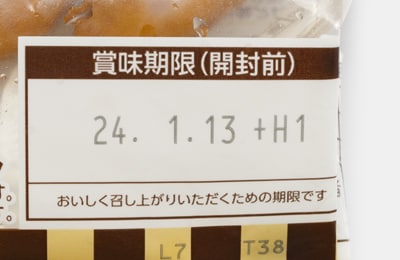

UV laser technology is widely used for marking expiration dates, batch numbers, and barcodes on films, labels, and foil wrappers.

What Major Advantages Does UV Laser Coding Have Over TTO for Marking in the Candy Industry?

UV laser coding offers zero consumables, no wear on parts, no maintenance, precise high-speed marking, and more eco-friendly production compared to traditional thermal transfer overprinting (TTO). It also delivers permanent marks that withstand tough environments, such as powder-filled or dusty settings.

How Does UV Laser Coding Enhance Product Safety in the Candy and Confectionery Industry?

Codes are permanent and tamper-proof to help maintain traceability, preventing counterfeiting and ensuring reliable and accurate product labeling.

What Makes UV Laser Marking Ideal for Product Traceability in the Candy and Confectionery Industry?

UV laser marks are permanent, legible, and tamper-proof, ensuring clear traceability across the supply chain for compliance and quality control.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)