Coding on Fruit and Vegetable Packaging with UV Laser Technology

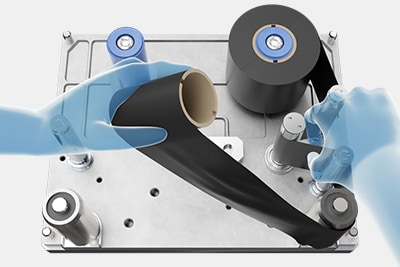

The food industry needs efficient, traceable packaging solutions; however, thermal transfer printers (TTO) can be costly due to frequent repairs and downtime.

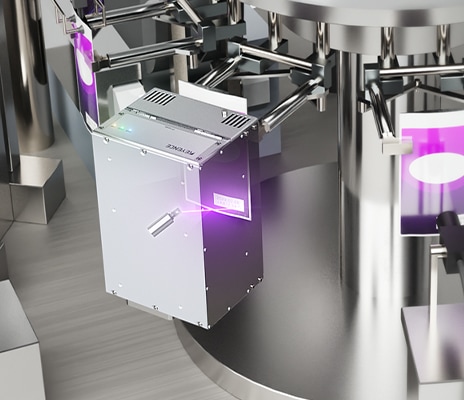

KEYENCE UV laser coders use ultraviolet light to create precise marks on packaging film by reacting with Titanium Dioxide, a common pigment in food packaging. This technology gets rid of consumables, creating a sustainable solution.

Conventional thermal printer

-

1Risk of marking that fades

-

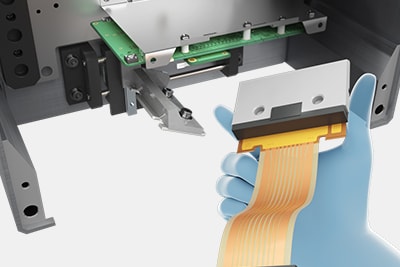

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

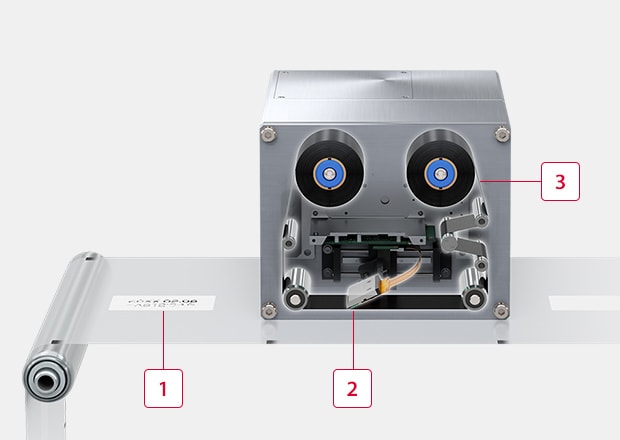

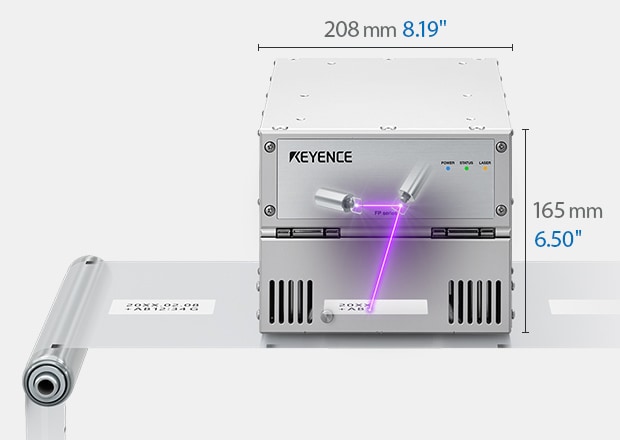

Replacement of current TTO is simple due to similar outer dimentions.

We’re here to provide you with more details.

Reach out today!

UV Laser Coding and Marking on Produce Packaging

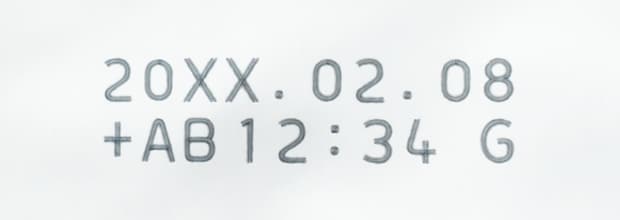

UV laser coding in the fruit and vegetable packaging industry is quickly becoming the preferred choice for produce packaging due to its efficiency and durability. Unlike traditional thermal transfer overprinters (TTO), UV lasers, like the FP-1000 Series, create permanent, smudge-resistant marks without consumables like ink ribbons, reducing both costs and waste. This advanced technology delivers precise, durable coding on various films in the wet and dirty environments produce is packaged in.

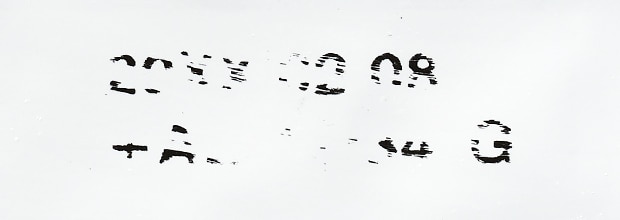

A key advantage of UV laser coding in the fruit and vegetable packaging industry is its ability to produce marks that remain intact under challenging conditions. Unlike ink-based systems, which can fade or fail on laminated or multi-layered surfaces, UV laser coding in the produce packaging industry is permanent and flawless, even when exposed to water, oils, dust/powders, or other contaminants. This reliability ensures clear traceability throughout the supply chain.

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Fruit and Vegetable Packaging Industry Challenges Solved By KEYENCE UV Laser Coder Technology

The fruit and vegetable packaging industry struggles with labeling challenges, needing innovative solutions to meet safety standards and maintain quality as traditional methods like TTO fall behind in the wet/tough environments of produce packaging.

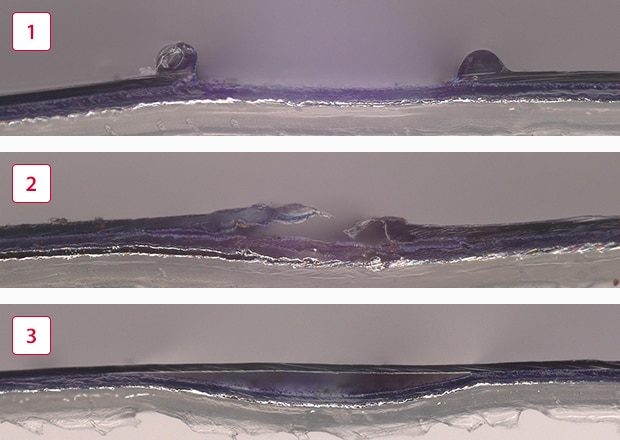

Marking Without Damage

A key issue is marking delicate produce without damage. Conventional infrared lasers, such as CO2 and fiber lasers, generate high heat that can damage or discolor sensitive materials, impacting appearance and marketability. The KEYENCE UV laser coder solves this with a non-contact process that eliminates heat, ensuring even fragile produce remains undamaged and visually pristine.

Cross section of marked film

-

1CO2 laser

-

2Fiber laser

-

3UV laser

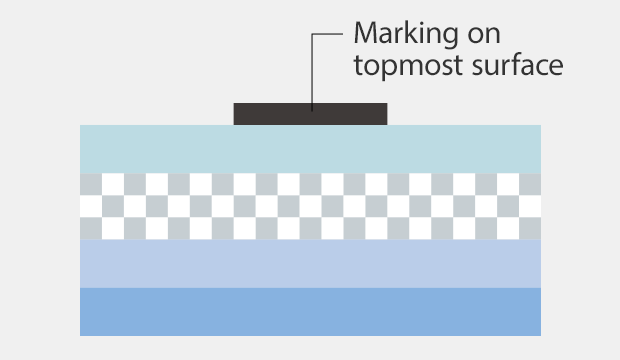

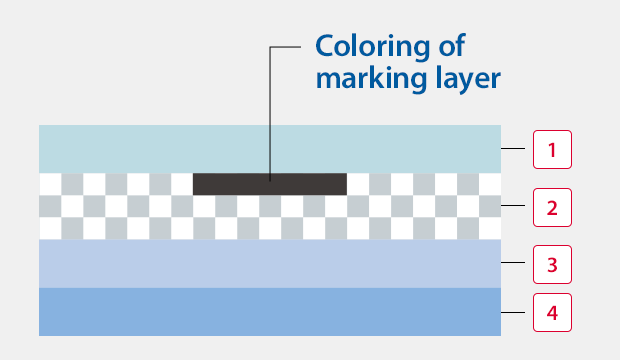

Conventional ink-based systems

UV laser coder

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

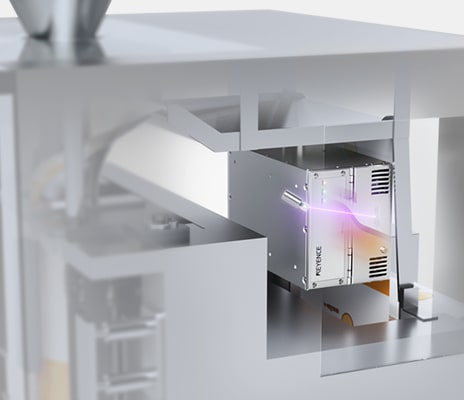

Harsh Packaging Environments

Another challenge is the harsh packaging environments, where refrigerated, humid, or dusty conditions can compromise labeling quality. The FP-1000 Series UV laser coder, with its IP65-rated design, resists water and dust, ensuring consistent performance. Its robust construction allows printing through water with no impact on permanence and cleaning without dismantling, minimizing downtime.

Easy Integration of Equipment

The FP-1000 Series offers an efficient upgrade for TTO users. Its compact size, flexible mounting (with a dedicated bracket), and compatibility with existing production lines enable quick adoption with minimal disruption or cost. By integrating the FP-1000 Series laser coder, businesses enhance efficiency without major production changes.

Contamination

Traditional ink-based printing risks contaminating food packaging through leakage, smudging, or transfer. The FP-1000 Series UV laser coder offers a safer, cleaner solution by using precise UV lasers to bond directly with packaging materials, eliminating the need for inks, solvents, or chemicals.

Curious about our pricing?

Click here to find out more.

Why Choose the FP-1000 Series for Fruit and Vegetable Packaging Marking Needs?

Discover why the FP-1000 Series is the perfect solution for all your fruit and vegetable packaging marking needs.

1. Smudge-Free Precision

While traditional thermal printers struggle with ink transfer and contamination, the FP-1000 Series’ UV laser delivers clean, contact-free markings every time, ensuring consistent quality and reducing risks.

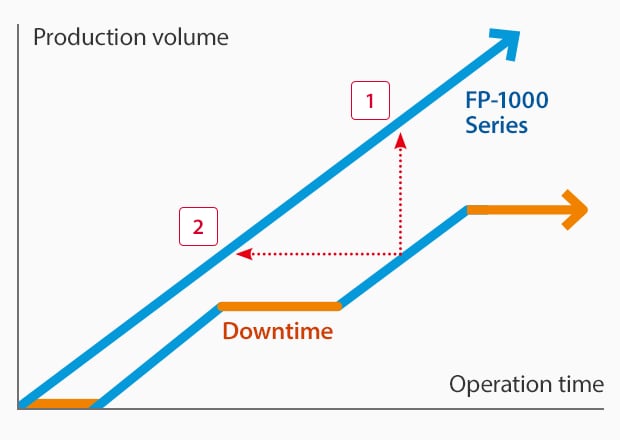

2. Minimal Downtime, Maximum Efficiency

Traditional printers require frequent ribbon replacements, causing interruptions and higher maintenance costs. The FP-1000 Series eliminates ribbons entirely, ensuring seamless production and improved efficiency to meet your operational goals.

No periodic parts replacement required

No periodic maintenance/inspection required

No ink ribbon costs

No head replacement costs

3. High-Speed Marking with Continuous Production

The FP-1000 Series is designed for high-speed production environments, providing precise and permanent laser markings without frequent maintenance interruptions. While marking speeds may vary based on character size, the elimination of consumables like ribbons and low-maintenance operation ensure maximum uptime and increased production.

-

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in the Fruit and Vegetable Packaging Industry

How Does the FP-1000 Series Laser Coder Ensure Long-Lasting and Legible Markings on Fruit and Vegetable Packaging?

FP-1000 Series laser coders use UV light technology to create durable, high-quality markings on various films and labels used in produce packaging. Unlike thermal printers, UV lasers bond directly with the surface, ensuring precise, long-lasting, and smudge-resistant results.

How Does UV Laser Coding Improve Traceability?

UV laser markings are permanent, highly legible, tamper-proof, and offer excellent contrast, making them easy to scan with barcodes or OCR systems. This ensures accurate tracking of produce from farm to shelf, detailing its origin and production methods.

What Maintenance Is Required for UV Laser Coding Systems in Fruit and Vegetable Packaging?

UV laser technology offers minimal maintenance for fruit and vegetable packaging. Unlike thermal printers, it requires no consumables like ribbons, print head cleaning, or parts replacements, making it hassle-free and efficient.

Are FP-1000 Series Laser Coders Suitable for Coding in Challenging Environments, Such as Refrigerated or Humid Conditions Common in the Fruit and Vegetable Packaging Industry?

UV laser technology is ideal for tough environments in the fruit and vegetable packaging industry. The FP-1000 Series, with its IP65 rating, is dust and water-resistant and performs reliably in high humidity and refrigerated settings.

How Does UV Laser Coding and Marking on Produce Packaging Impact Sustainability?

UV laser coding in the fruit and vegetable packaging industry is an eco-friendly solution for fruit and vegetable packaging, eliminating ink ribbons and reducing waste. It uses less energy than traditional printing, supporting sustainability and lowering carbon footprints.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)