Coding on Packaged Foods with UV Laser Technology

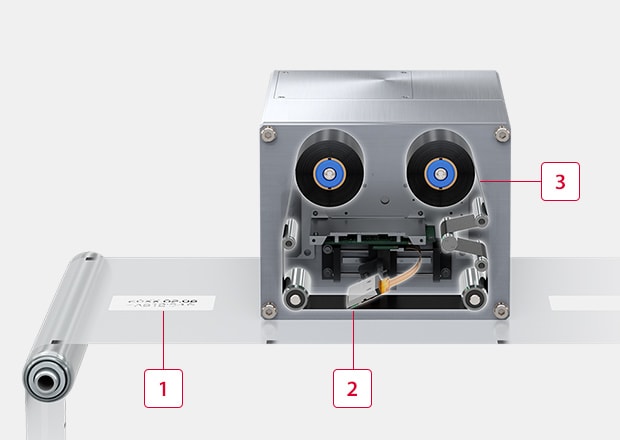

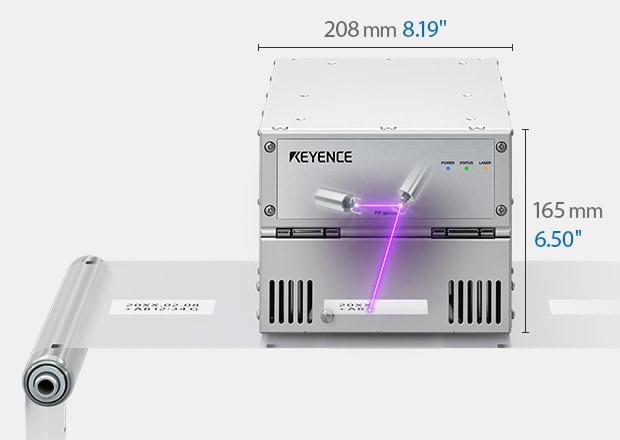

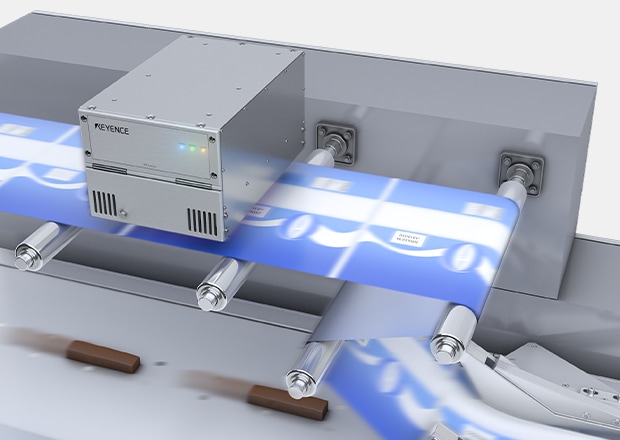

The FP-1000 Series UV laser coder offers a seamless upgrade for coding on packaged foods, replacing traditional thermal transfer overprinters (TTO) without altering film or machinery. Its UV laser technology and features deliver precise, durable codes. Eliminate your consumables, waste, parts, and downtime to improve production line efficiency and traceability.

Conventional thermal printer

-

1Risk of marking that fades

-

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

Replacement of current TTO is simple due to similar outer dimensions.

We’re here to provide you with more details.

Reach out today!

UV Laser Coding and Marking on Packaged Foods

KEYENCE’s FP-1000 Series UV laser coder excels in marking on packaged food materials, offering high-quality coding on packaging like multilayer films, foils, and paper-based materials used for:

- Snack Foods: Chips, Candy, Yogurt, Granola Bars

- Dairy Products

- Frozen Foods

- Cereal

- Coffee

- Pet Food

- Meat Products

- Baked Goods

- Pastas

- Sauces and Condiments

Curious about our pricing?

Click here to find out more.

Packaged Foods Challenges Solved by KEYENCE First UV Laser Coder Technology

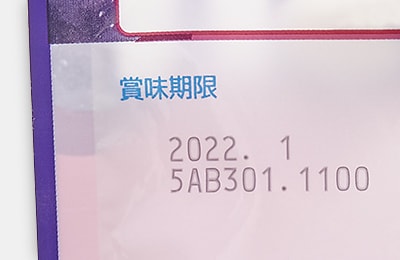

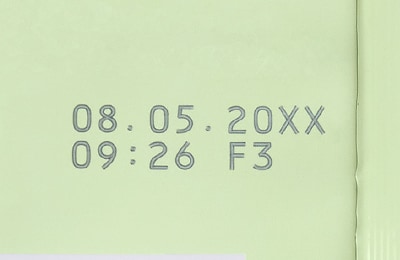

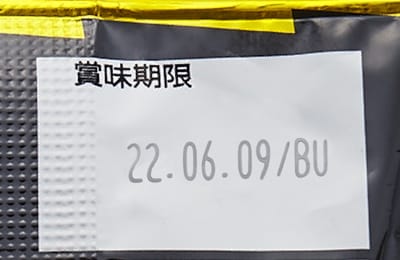

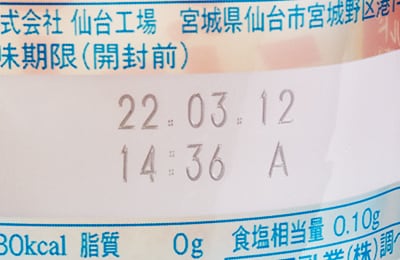

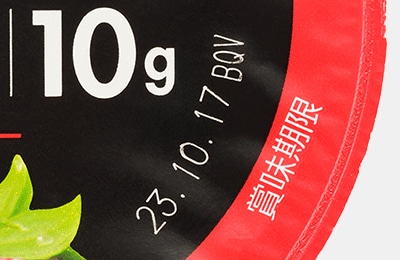

Mark Permanence

Ink fading is a common issue on various food packaging, making codes hard to read. The FP-1000 Series delivers high-contrast, permanent marks for consistently legible results.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

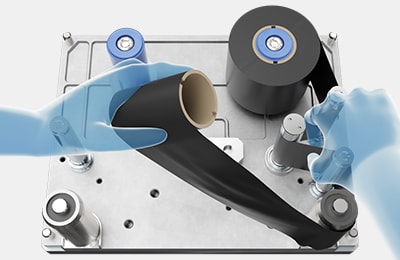

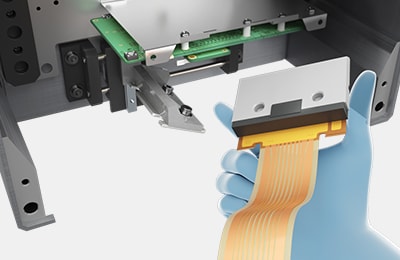

Expensive Consumables and Parts

Traditional methods like thermal transfer overprinting (TTO) require consumables and parts, such as ribbons and print heads. The FP-1000 Series’ light-based technology eliminates the need, reducing expenses.

No ink ribbon costs

No head replacement costs

No air-related costs

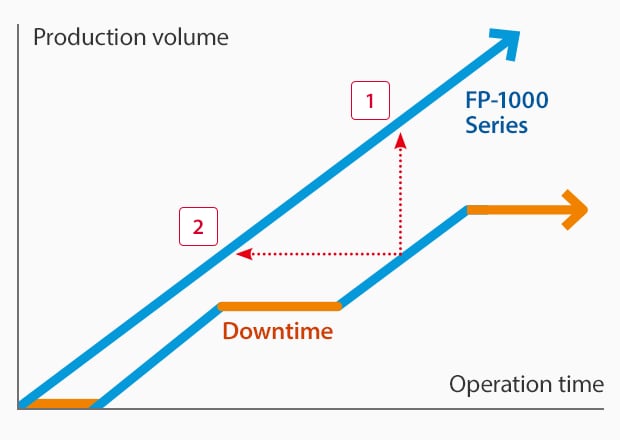

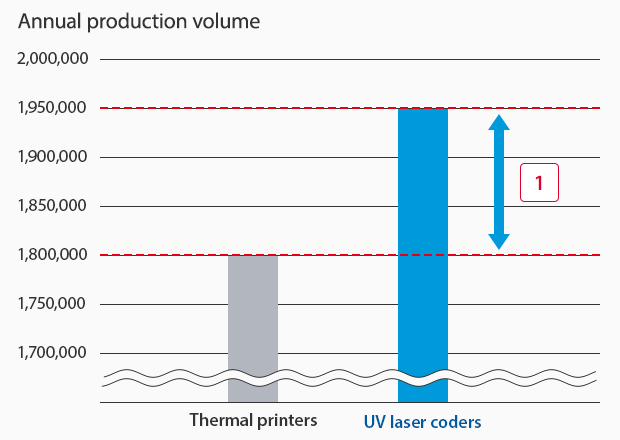

Costly Downtime

Thermal transfer overprinting (TTO) requires frequent production stops and incurs costly downtime to replace ink ribbons and parts. With the FP-1000 Series’ consumable-free, non-contact marking, downtime is minimized.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Line conditions:

100 operations/minute, 10 hours/day, 25 days/month, 1 ink ribbon replacement/day at 5 minutes/ribbon replacement.

-

1When operated at the same operation time:

150,000 units more per year

* When producing the same production volume: 1,500 minutes (2.5 days) less per year without the need to replace ink ribbons

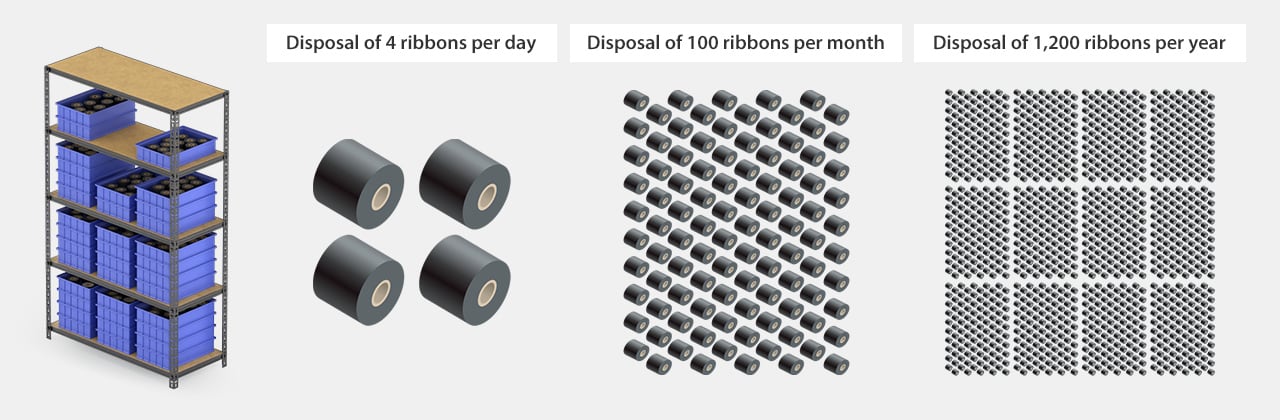

Environmental Friendliness

Traditional coding methods often produce waste. The FP-1000 Series’ UV laser coding on packaged foods offers eco-friendly operation, helps reduce waste and supports sustainability efforts.

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Why Choose the FP-1000 Series for Packaged Foods Marking Needs?

The FP-1000 Series provides precise, high-speed, and reliable non-contact UV laser coding and marking on packaged foods. This technology eliminates downtime and consumable costs, offering eco-friendly, permanent marks. Easily integrate the FP-1000 Series into your production line to simplify operations, reduce costs, and enhance product marking. Contact us today to see how a UV laser coder can streamline your production and reduce operational costs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Packaged Foods

How Does UV Laser Coding Improve the Traceability of Packaged Foods?

UV laser coding meets packaged foods’ laser marking needs by providing high-precision, tamper-proof markings that enhance product traceability, ensuring food safety and simplifying recall processes.

How Does UV Laser Marking Ensure Permanence and Damage-Free Marks in Packaged Food Labeling?

UV laser marking creates indelible, high-contrast codes without physical contact, guaranteeing durable, clear marks on packaging materials without risk of damage.

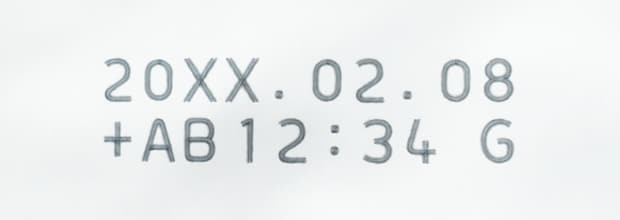

What Types of Markings Can Be Achieved with FP-1000 Series Laser Coders on Packaged Foods?

The FP-1000 Series laser coder can mark batch codes, barcodes, expiration dates, and lot numbers on packaged foods with clarity and precision.

How Does UV Laser Coding Reduce Production Losses Associated with Line Stoppages in the Packaged Food Industry?

UV laser coding eliminates the need for consumables, minimizing interruptions due to ribbon or head replacement, which significantly reduces production downtime.

How Do UV Laser Coders Contribute to Reducing Waste in Packaged Food Production?

UV laser coders are consumable-free, meaning no ribbons or print heads, which helps lower waste production and supports eco-friendly manufacturing practices.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)