Coding on Snack Packaging with UV Laser Technology

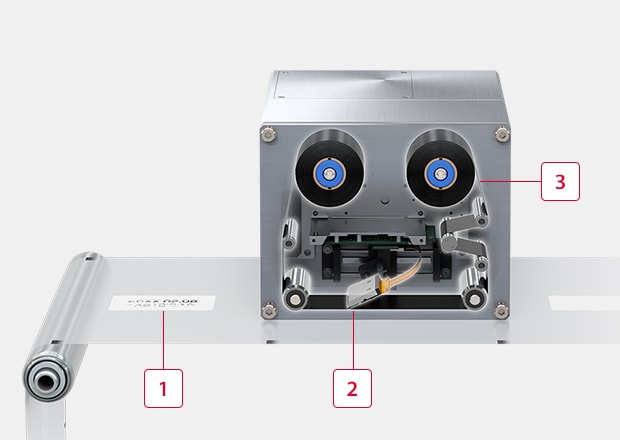

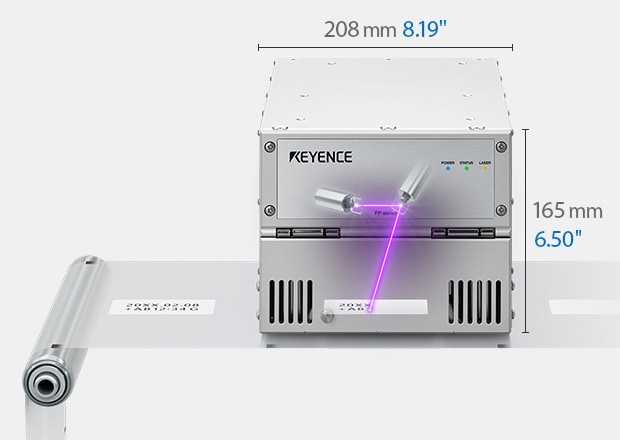

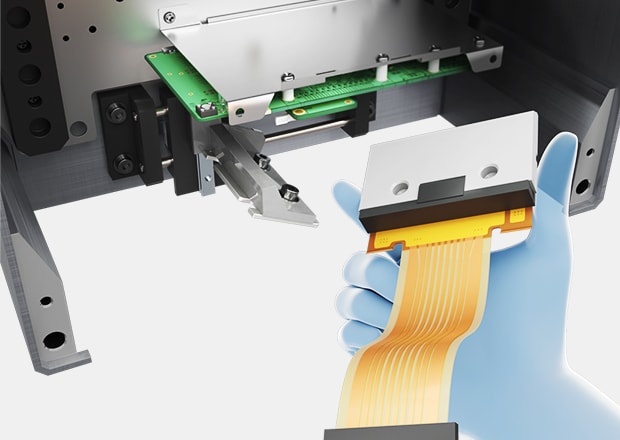

The FP-1000 Series UV laser coder particularly suited for applications in the food and beverage industry and is an optimal choice for coding in the snack packaging industry, seamlessly replacing traditional thermal transfer overprinters (TTO) without any changes to the film or machinery. With UV laser technology, you can reduce waste and scrap while doing away with consumables and downtime.

Conventional thermal printer

-

1Risk of marking that fades

-

2Thermal head replacement

-

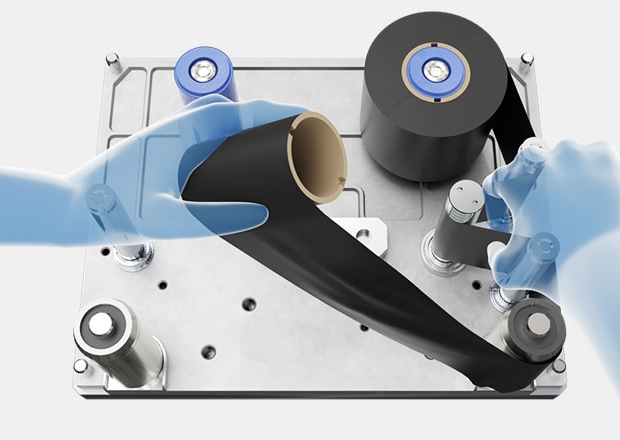

3Ink ribbon replacement required

UV laser coders

Replacement of current TTO is simple due to similar outer dimensions.

We’re here to provide you with more details.

Reach out today!

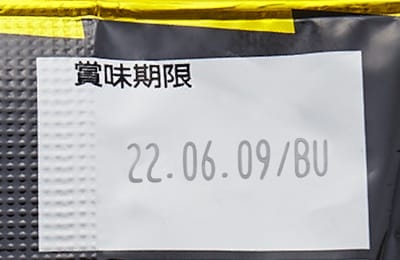

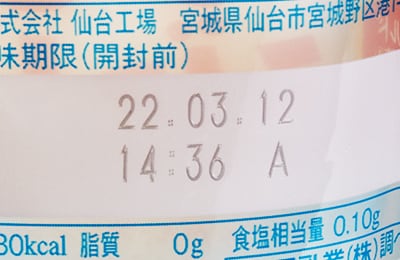

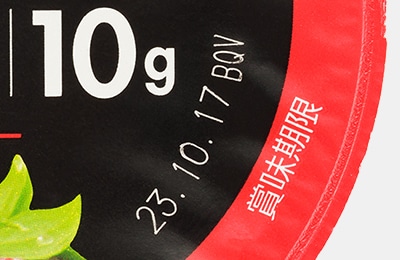

UV Laser Coding and Marking on Snack Packaging

The FP-1000 Series UV laser coder is perfect for candy packaging, delivering high-quality, precise codes on materials like multilayer films, foils, and paper-based wraps used frequently for:

- Candy

- Chips

- Yogurt

- Granola Bars

- Trail Mix

- Chewing Gum

- Cookies

Curious about our pricing?

Click here to find out more.

Snack Packaging Challenges Solved by KEYENCE First UV Laser Coder Technology

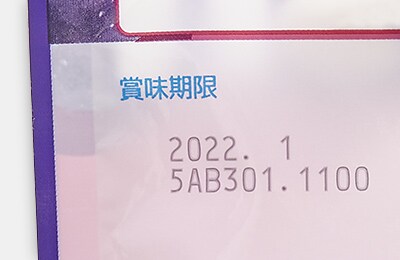

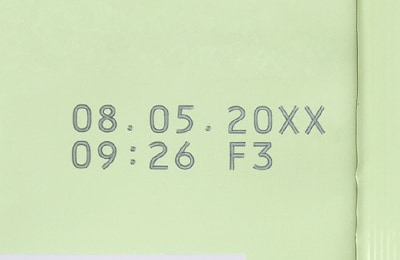

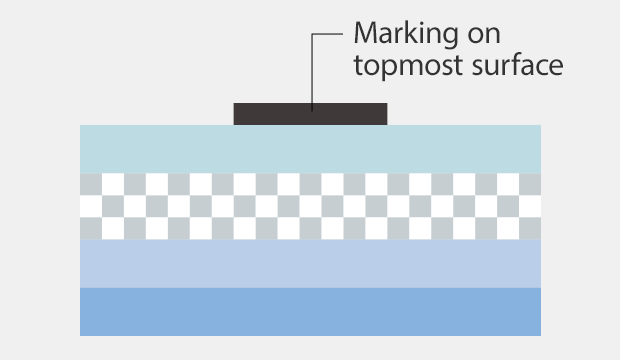

Durable and Permanent Markings

Ink fading is a frequent issue in candy packaging, making codes hard to read. The FP-1000 Series provides sharp, permanent marks for clear, traceable results.

Conventional ink-based systems

UV laser coder

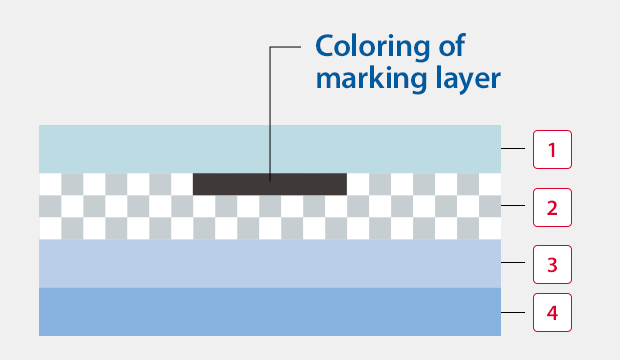

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Conventional thermal printer

UV laser coder

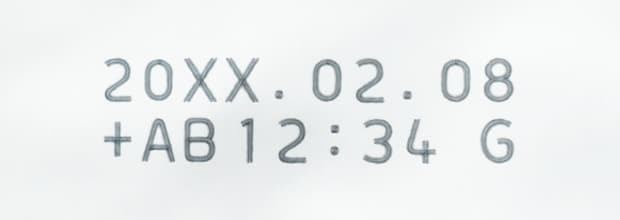

* Results comparison after rubbing on the marked area of film exposed to powder before marking

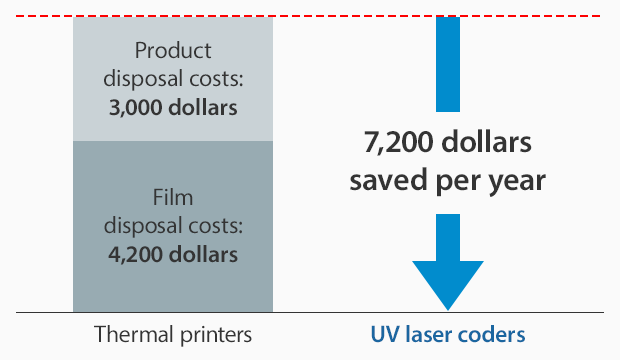

High Costs for Consumables

TTO needs ribbons and print heads. The FP-1000 Series’ UV laser eliminates these consumables, reducing costs significantly.

No ink ribbon costs

No head replacement costs

Cost reduction example:

With film costs of 0.04 dollars/sheet, 350 sheets of film wasted/day at a product unit price of 1 dollar/item and with product waste of 10 items/day, operating for 25 days a month.

Operating energy for packaging line equipment (packaging machine, compressor, air conditioner, lighting, etc.) can be significantly reduced.

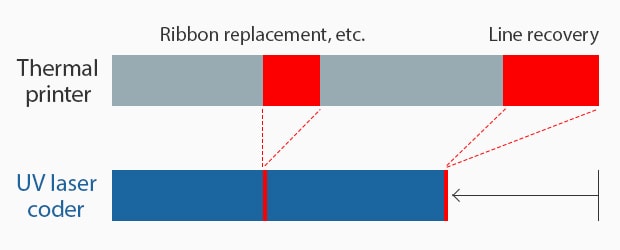

Unwanted Downtime

TTO methods require frequent stops for ribbon and part replacement, causing downtime. The FP-1000 Series’ non-contact marking minimizes interruptions and keeps production moving.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Eco-Friendly Operation

Conventional coding methods create waste. The KEYENCE FP-1000 Series' UV laser coding and marking on snack packaging reduces waste in candy packaging, supporting eco-friendly and sustainable practices.

Why Choose the FP-1000 Series for Snack Marking Needs?

The FP-1000 Series delivers precise, high-speed, and reliable non-contact UV laser coding in the snack packaging industry. Advanced coding technology removes the need for consumables and reduces downtime, creating eco-friendly, permanent marks. Seamlessly integrate the FP-1000 Series into your production line to simplify operations, lower costs, and improve product marking quality. Discover how UV laser coding can enhance your candy packaging process and reduce operational expenses by contacting us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in Snack Packaging

Can UV Laser Coders Handle the High-Speed Production Lines Typical in Snack Packaging?

Yes, a UV laser coder like the FP-1000 Series is optimized for high-speed lines, delivering precise, fast, and consistent marking without compromising clarity.

What Cost Savings Can Snack Manufacturers Expect from UV Laser Coding Technology?

UV laser coding eliminates consumable costs (such as ink and print heads), eliminates maintenance expenses, and significantly reduces downtime, resulting in significant long-term savings.

Can UV Laser Coding Prevent Marking Issues Caused by Oil or Powder on Snack Packaging?

UV laser technology provides non-contact, high-contrast marks that are unaffected by oils or powders on packaging surfaces, ensuring consistent readability.

How Does UV Laser Coding Ensure Permanent and Damage-Free Markings on Snack Packaging?

UV laser coders deliver durable, tamper-proof marks that won’t fade or wear off, providing long-lasting quality without damaging the packaging.

Why Are FP-1000 Series Laser Coders Preferred Over Ink-Based Systems for Snack Packaging?

FP-1000 Series coders are chosen for snack packaging laser marking needs due to low maintenance, eco-friendly operation, and reliable, consumable-free marking, which reduces waste and operational costs.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)