UV Laser Coding and Marking on Paper Product Packaging

Coding in the paper product packaging industry must withstand fast production speeds, varying material finishes, and environmental factors like moisture and coatings. Regardless of the products being packaged, manufacturers require coding solutions that combine accuracy with adaptability to different materials and production issues—without slowing down operations or increasing waste.

Paper Product Packaging Industry Challenges Solved by KEYENCE UV Laser Coder Technology

Traditional ink-based coders often struggle with smudging, fading, and material waste. The following factors in the paper product packaging industry highlight the need for a solution that offers both precision and efficiency.

Material Variability

Glossy coatings, recycled paper, and porous surfaces affect ink adhesion and print clarity, leading to inconsistent codes.

Frequent Rework

Porous or coated paper requires ongoing ink calibration to prevent smudging, fading, or bleeding.

Conventional ink-based systems

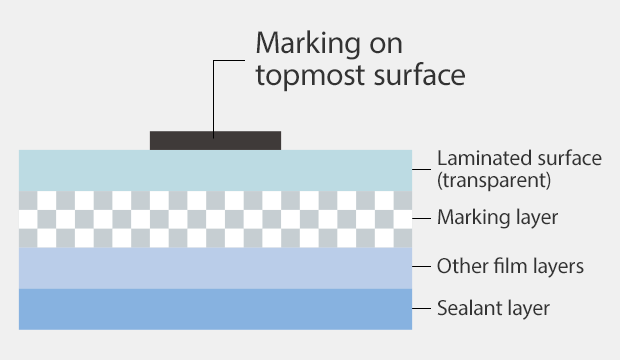

UV laser coder: No ink transfer after marking

High-Speed Production Demands

Paper packaging lines operate at high speeds, making it difficult for traditional ink-based coders to keep up without causing smudging or misalignment.

Regulatory Compliance

Paper-based packaging for food, pharmaceuticals, and consumer goods must meet strict traceability and labeling regulations.

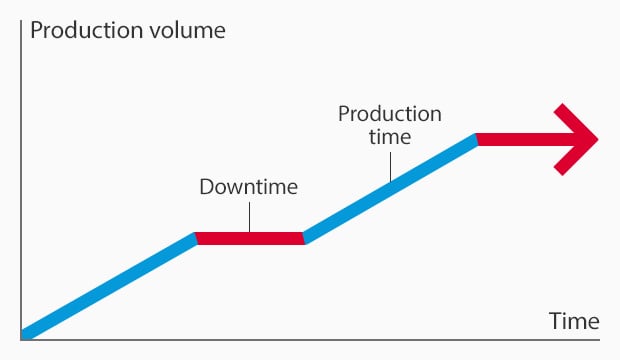

Operational Costs & Downtime

Ink-based systems require regular refills, printhead cleanings, and costly consumables.

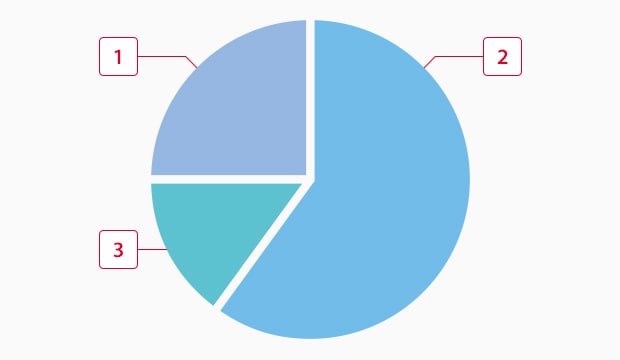

Example of expected costs

-

1Maintenance and inspection costs

-

2Ink ribbon costs

-

3Thermal head costs

An effective and environmentally responsible solution for the paper packaging sector, a UV laser coder offers a sharper, more dependable substitute that produces clear, permanent codes without the need for ink, ribbons, or regular maintenance.

We’re here to provide you with more details.

Reach out today!

Why Choose the FP-1000 Series for Paper Product Packaging Laser Marking Needs?

The FP-1000 Series laser coder from KEYENCE delivers precise, durable, and cost-effective markings for packaging materials in the paper product sector, including tissues, diapers, and wipes. Due to its low maintenance needs, consumable-free operation, and user-friendly design, these coders help businesses streamline procedures, reduce costs, and maintain high standards of quality.

The FP-1000 Series is specifically engineered to meet the demands of coding in the paper product packaging industry, offering:

Precise, Non-Contact Marking

Ensures accurate coding on paper packaging without damaging the contents.

Higher Quality Marks

Provides higher-quality marks that remain unaffected by contaminants, friction, alcohol, heat, or transportation damage.

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

No periodic parts replacement required

No periodic maintenance/inspection required

Consumable-Free Technology

Reduces operational costs by eliminating the need for inks, ribbons, or replacement parts.

Permanent, Damage-Free Markings

Permanent marks resist smudging and fading without damaging the paper substrate, ensuring codes remain legible throughout transportation and storage.

User-Friendly Design

Intuitive controls and minimal maintenance make the FP-1000 Series ideal for busy production environments.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Technology in the Paper Product Packaging Industry

How Does UV Laser Coding Improve the Durability of Markings on Paper Product Packaging?

UV laser coders create permanent, high-contrast markings resistant to smudging, friction, and environmental factors like oils, heat or humidity. This ensures codes remain legible throughout the product’s lifecycle.

Can UV Laser Coders Be Used to Mark Paper Product Packaging Without Damaging the Contents?

Yes, UV laser coders use non-contact technology that applies precise markings to the packaging material without affecting the integrity of the product itself.

How Does UV Laser Coding Help Reduce Operational Costs in Paper Product Packaging Compared to Traditional Methods?

UV laser coding in the paper product packaging industry drastically cuts material costs and downtime related to restocking parts by doing away with consumables like inks and ribbons, which lowers overall costs.

What Maintenance Is Required for UV Laser Coders Used in Paper Product Packaging?

UV laser coders require zero maintenance, so say goodbye to troubleshooting issues, reworking from poor or missing marks, replacing parts, and dealing with production interruptions.

Is Special Training Required to Operate UV Laser Coders for the Paper Product Packaging Industry?

No extensive training is needed. Operators without specialized knowledge can easily set up, modify, and operate the FP-1000 Series thanks to its user-friendly interface.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)