How UV Laser Coders Reduce Waste and Support Sustainability Initiatives

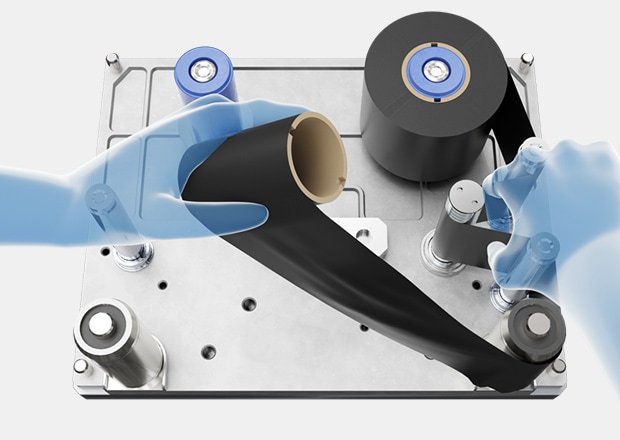

Coding systems aren’t usually the first place manufacturers look when aiming to reduce waste, but they should be. Each ink cartridge, ribbon spool, and solvent bottle used in thermal or ink-based printers adds to the ever-growing pile of industrial waste. This not only complicates compliance with regulations but also works against larger sustainability goals. UV laser coders, like the KEYENCE FP-1000 Series, remove the need for consumables entirely, offering a cleaner and more straightforward method for marking products.

The Role of UV Laser Coding in Sustainable Manufacturing

The pressure to hit sustainability goals isn’t just a company directive, as manufacturers deal with tighter regulations and more scrutiny around how much waste their operations produce.

UV laser coding machines remove an entire category of waste without complicating existing workflows. Unlike traditional marking systems that rely on consumables, UV laser coders help manufacturers reduce waste. There are no ink cartridges to dispose of, no ribbons to replace, and no solvents needed to operate the system. For facilities looking for a practical solution, laser coding machines can help reduce materials that often end up in landfills or require costly disposal.

In industries like food, beverage, and pharmaceuticals, where clean production environments matter just as much as efficiency, UV laser coders also help eliminate common contaminants without having to sacrifice crisp, durable markings.

We’re here to provide you with more details.

Reach out today!

How UV Laser Coders Eliminate Consumables and Reduce Waste

Typical coding setups involve numerous moving parts and disposable components. In contrast, UV laser coders use ultraviolet light to create a chemical reaction within the top layer of a material. The result is a sharp and permanent mark that requires no physical supplies. This method is also heatless (making it perfect for heat-sensitive packaging like styrofoam or films) and non-contact, allowing markings to be made on thin and flexible packaging without compromising on quality.

UV laser coders reduce waste by removing consumables entirely, simplifying day-to-day production. In standard packaging environments, switching to UV laser coding has the potential to eliminate more than 1.2 tons of ribbon waste annually.

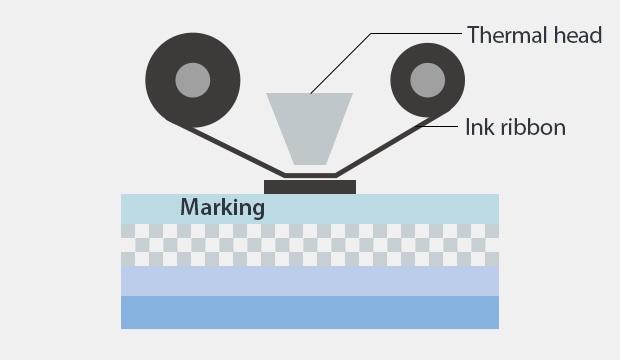

Thermal printers

Marking is affected by surface conditions because the ink is transferred onto the film surface.

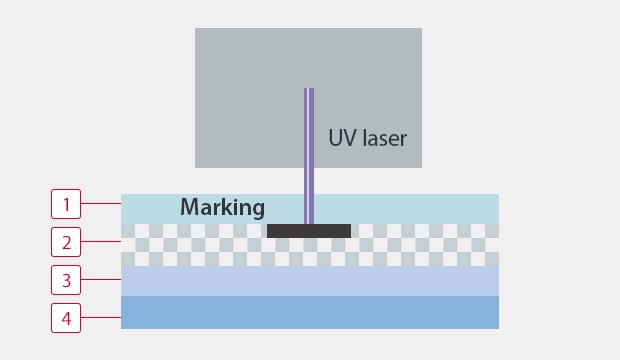

UV laser coders

The marking dose not fade because the color of the marked layer of the film is changed.

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Cost Savings and ROI Benefits of Sustainable UV Laser Marking

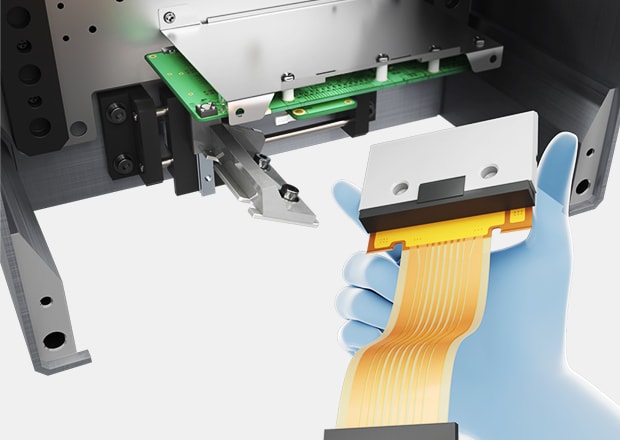

For many manufacturers, sustainability is often framed as an additional cost. However, with UV laser coders, it is the opposite; not only do these UV laser printing machines reduce waste, but they also help cut down on daily operating expenses. Operators may find the cost savings immediately, as there is no ink, ribbons, or solvents to order. There are also no printheads to clean or nozzles to unclog, meaning there is no need to shut down the production line.

The additional uptime adds up, and, by removing the constant maintenance required by other printers, production lines could free up enough time to produce an estimated 150,000 more units a year.

With fewer consumables to manage, there is also a reduction in storage, less waste handling, and fewer material-related delays. UV laser coders are low-maintenance and are designed with minimal intervention, keeping long-term upkeep costs down.

No ink ribbon costs

No head replacement costs

Industries that Benefit from UV Laser Coding for Sustainability

For industries that need clear and durable markings for traceability that can be printed at high speeds, UV laser coders offer a practical way to meet those goals while reducing waste and removing chemical-based supplies from the process.

For the food and beverage industry, packaging often involves thin films, pouches, or coated cartons — materials that can be hard to mark cleanly with ink-based systems. UV laser printing machines produce sharp and permanent marks that do not smear or fade, even when oil, powders, or heat is involved. They also create a cleaner packaging environment as, with the elimination of ribbons and inks, there are fewer elements to contaminate the product. This is especially important in dairy and frozen food production, where outside bacteria can compromise health and safety regulations.

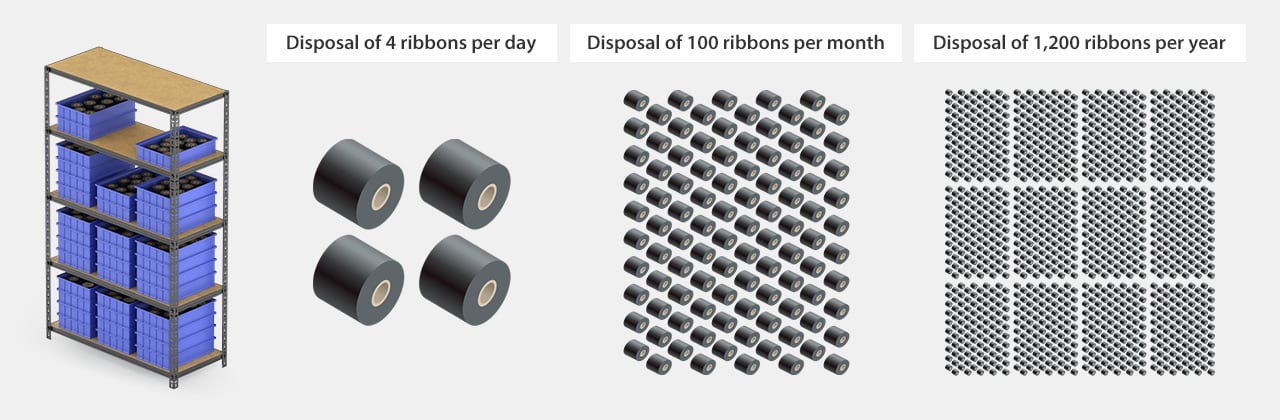

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

Pharmaceuticals and medical device manufacturers also have to operate under strict cleanliness standards. Packaging has to be legible, traceable, and tamper-resistant. UV laser coders support these needs while also reducing material use and eliminating the need to stock and dispose of ink-related supplies. Whether needing to mark individual pills or PVC tubing for IVs, UV laser printing helps companies meet their environmental target without compromising safety.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About UV Laser Coders and Sustainability

How Does UV Laser Coding Improve Energy Efficiency?

UV laser coders use a cold marking process that requires no heat and minimal power to create a mark. Compared to thermal transfer or inkjet systems, they consume less energy per unit and eliminate the additional energy demands tied to ribbon heating or solvent processing.

Can UV Laser Coders Help Meet Sustainability Regulations?

Yes. Because they operate without inks or solvents, UV laser coders avoid releasing volatile organic compounds (VOCs) and other hazardous emissions, helping meet environmental compliance and packaging sustainability standards more easily.

Does UV Laser Marking Impact Packaging Recyclability?

No. Since UV laser coders don’t apply ink or adhesives to the surface, they leave packaging materials uncontaminated and fully recyclable. This helps maintain the integrity of sustainable substrates like recyclable films and coated cartons.

Is UV Laser Coding Safe for Food and Pharmaceutical Packaging?

Yes. The non-contact is safe for use on packaging that comes into contact with consumables. It also reduces the risk of contamination by removing inks, solvents, and ribbon debris from the production line.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)