Maximizing ROI with a UV Laser Coder: Cost-Effective, High-Precision Marking

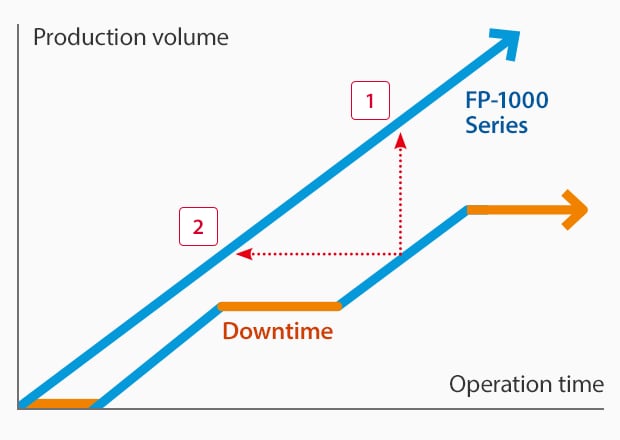

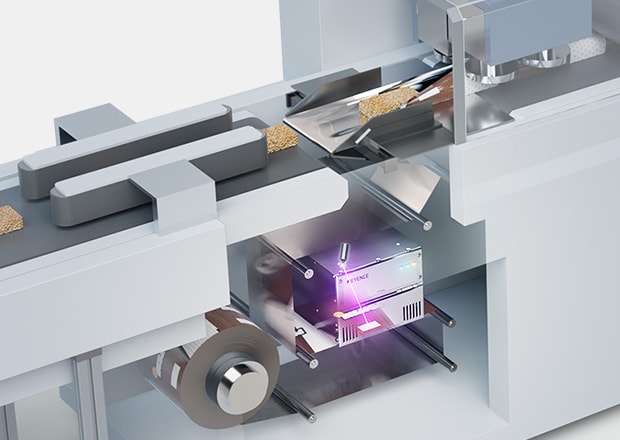

Investing in the KEYENCE FP-1000 Series UV laser coder can significantly enhance profitability by eliminating hidden costs associated with traditional marking systems and reducing downtime for maintenance.

-

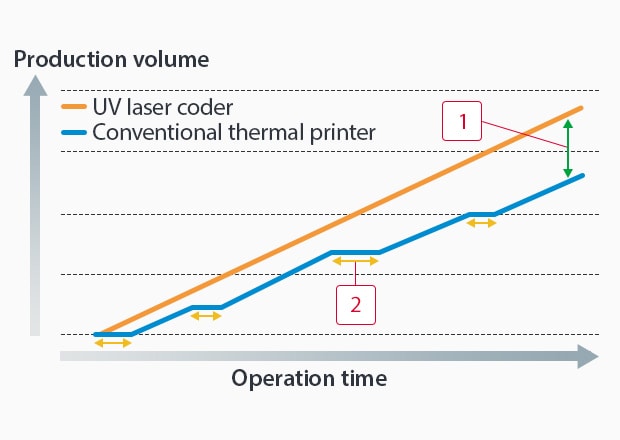

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Why ROI Matters for Industrial Marking

Not all marking systems are created equal; some come with hidden costs that add up. In manufacturing, products must be identifiable throughout the supply chain for traceability, brand integrity, and regulatory compliance. Many manufacturers still rely on TTO or ink-based systems, which hide costs that reduce profitability. Even brief stoppages for maintenance compound over time, reducing throughput and creating inefficiencies.

KEYENCE FP-1000 Series UV laser coder is a newly built technology that can replace TTO and ink-based marking systems, eliminating the need for costly consumables and reducing downtime related to maintenance. The return on investment (ROI) on laser coders is immediate, whether that is in lower operational costs due to less downtime or increased productivity and profitability.

No ink ribbon costs

No head replacement costs

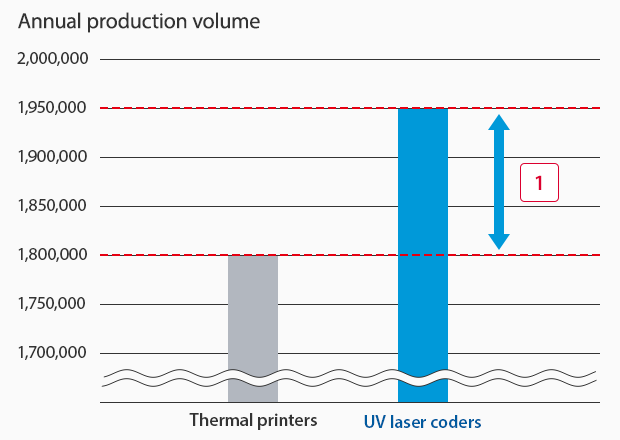

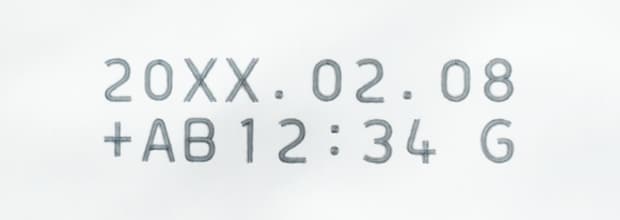

Line conditions:

100 operations/minute, 10 hours/day, 25 days/month, 1 ink ribbon replacement/day at 5 minutes/ribbon replacement.

-

1When operated at the same operation time:

150,000 units more per year

* When producing the same production volume: 1,500 minutes (2.5 days) less per year without the need to replace ink ribbons

Curious about our pricing?

Click here to find out more.

Cost Savings with a UV Laser Coder

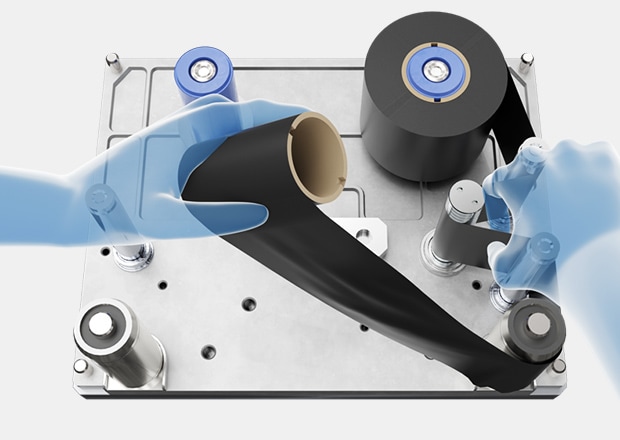

Every manufacturer looks for ways to cut costs without having to sacrifice quality or efficiency. Traditional marking systems need a constant stream of consumables or routine maintenance. These ongoing costs can eat into profits. By replacing ink and ribbons with light-based marking, the FP-1000 Series UV laser coder offers a smarter and more cost-effective alternative to TTO or ink-based systems, including:

No periodic parts replacement required

No periodic maintenance/inspection required

- No consumable costs: Ink, ribbons, and solvents can be costly as they have to be continually purchased. UV laser coders provide permanent, high-quality markings with zero consumables.

- No routine maintenance costs: With no ink ribbons to replace or printheads to clean, there is no need for frequent downtime to service the machine.

- Lower labor costs: Operators spend less time dealing with maintenance and cleaning, which frees them up to perform higher-value tasks.

- Eco-friendly initiatives: Without ink cartridges and cleaning solvents, waste is dramatically reduced, which cuts down on disposal costs and environmental impact.

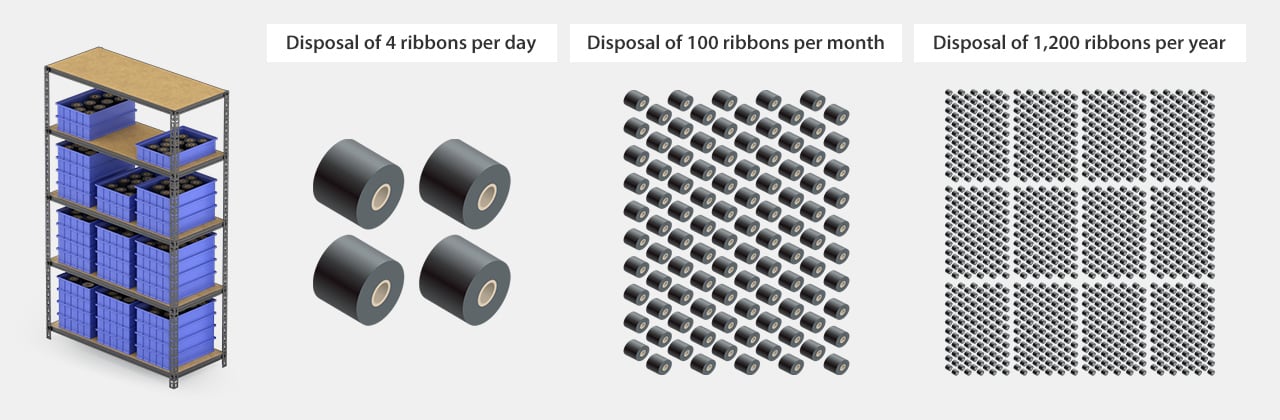

Disposal loss simulation:

For a facility that replaces four ink ribbons per day, operating at 25 days per month will lead to disposal of 1,200 ink ribbons per year. At 500 grams 17.65 oz per ink ribbon, 1,200 ink ribbons would equal 600 kilograms 1322.76 lb, or about 1.2 tons of CO2 emissions upon disposal. UV laser coders, however, do not use ink ribbons, so the CO2 emissions can be reduced to zero.

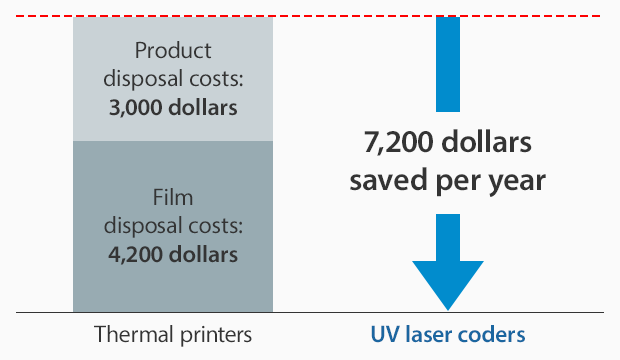

Cost reduction example:

With film costs of 0.04 dollars/sheet, 350 sheets of film wasted/day at a product unit price of 1 dollar/item and with product waste of 10 items/day, operating for 25 days a month.

Efficiency and Productivity Gains

TTO and ink-based systems have inherent inefficiencies, such as the need for operators to stop and change ribbons or troubleshoot marking issues.

These systems also struggle with maintaining workloads in high-speed facilities. A UV laser coder eliminates these inefficiencies through:

No ink transfer after marking

- Increased throughput: Fewer interruptions mean more products are marked per hour, improving overall line efficiency and maximizing ROI.

- Reduced downtime and maintenance: Traditional large machines are often difficult and inefficient to start and stop for frequent maintenance. The FP-1000 Series requires minimal maintenance and little downtime.

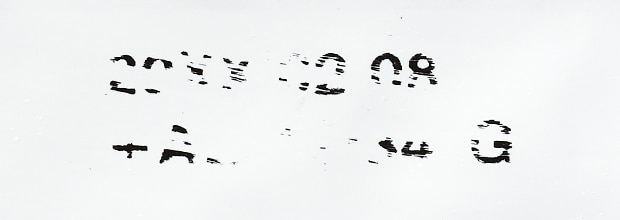

- No post-marking smudging: Ink-based systems require drying time before handling, otherwise the marking may smudge. UV laser coding is instantly permanent, resistant to wear, and won’t degrade over time.

-

1UV laser coders can mark more products in the same operating time

-

2Downtime due to ink ribbon replacement and thermal head cleaning

Discover more about this product.

Click here to book your demo.

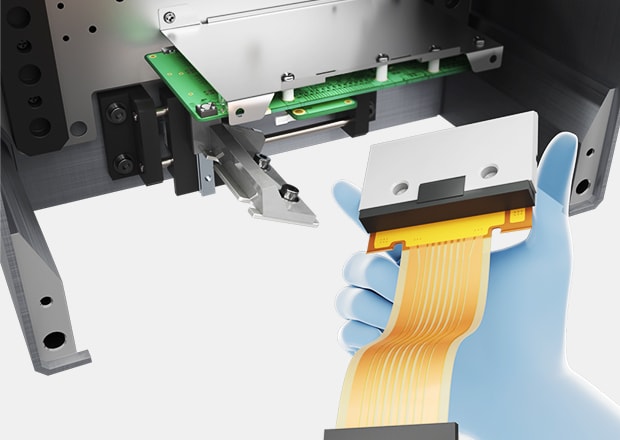

Long-Term Durability

When investing in industrial equipment, especially marking equipment, lifespan matters. Many TTO and ink-based printers have a working life of five to 10 years at best with regular maintenance and part replacements. Over time, the costs of replacing printheads, ribbons, and system maintenance add up, diminishing profitability.

The KEYENCE FP-1000 Series UV laser coder is built for longer-term (10-20 years) high-speed use, which makes it one of the most cost-effective marking solutions available. UV laser coders feature a solid-state design that eliminates moving parts that wear out. They are also engineered for continuous operation in high-speed and high-volume environments without interruption, resulting in significantly lower ongoing costs and higher efficiency. By the time you replace the FP-1000 Series, you’ll likely have gone through two or three TTO printers with their consumables and parts. Each mark from the FP-1000 Series boosts efficiency while lowering total cost of ownership (TCO) and overall facility expenses.

Unlike thermal printheads, which require constant part replacements, the FP-1000 Series UV laser uses The KEYENCE advanced diode technology, which delivers top performance without the frequent part replacements of thermal printheads. Known for durability and reliability, KEYENCE lasers outperform traditional TTO systems and other laser brands, offering a superior, long-lasting solution. The IP65-rated laser is also dust-proof and moisture-resistant and will not be compromised even in harsh environments.

Industries That Benefit the Most from UV Laser Coding

From food packaging to semiconductor manufacturing, many industries rely on clear and regulation-compliant marking to maintain quality and traceability. However, as many traditional marking systems struggle with faded or smudged markings, UV laser coders can eliminate these issues.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

In the food and beverage industry, sanitary markings are a top priority. Unlike ink-based systems, which also pose contamination risks, UV laser coding applies batch numbers, expiration dates, and other traceable information directly into flexible films, cartons, and thin, plastic packaging without affecting product safety. For industries like cosmetics, personal care products, and pharmaceuticals, UV laser coding ensures consistent, high-quality, and permanent markings that won’t fade over time, which makes UV laser coding an efficient and permanent solution. Across various industries, KEYENCE FP-1000 Series UV laser coders provide a cost-effective and maintenance-free alternative.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About ROI on UV Laser Coding

What Are the Cost Savings Compared to Inkjet Printers?

UV laser coders eliminate the need for ink, ribbons, and solvents, significantly reducing operating costs compared to TTO systems. Unlike TTO printers, which usually require frequent printhead replacements and ribbon changes, UV laser coders operate without wear-prone parts, cutting down on repair and maintenance expenses.

What Industries Benefit the Most from UV Laser Coders?

Industries that require permanent marking benefit the most from UV laser coders, including but not limited to: food, beverage, pharmaceuticals, and medical device manufacturers. Whether the need is for markings that don’t fade or for anti-counterfeiting measures, UV laser coders provide a solution.

How Does a UV Laser Coder Improve Traceability and Compliance?

UV laser coders create permanent, high-contrast markings that remain legible even under heat, moisture, and chemical exposure; they must comply with FDA and other regulatory standards. For industries that require tracking codes, UV laser coding can print batch numbers and serial numbers so that a product can be tracked throughout its lifecycle.

Is a UV Laser Coder More Durable Than Traditional Marking Methods?

Yes, UV laser coders last significantly longer than TTO, ink-based, or CO2 laser systems because they use advanced proprietary diodes. KEYENCE stands out as one of the few manufacturers designing and producing lasers entirely in-house. This vertical integration ensures superior diode quality and heat dissipation, key to maximizing laser lifespan. Unlike thermal printheads that degrade or inkjet nozzles that get clogged, UV laser coders maintain their precision over time.

How Does a UV Laser Coder Reduce Waste?

Without ink-based printing, there is no need for ink cartridges, ribbons, and cleaning solvents, reducing consumable waste and environmental impact produced by a manufacturer.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)