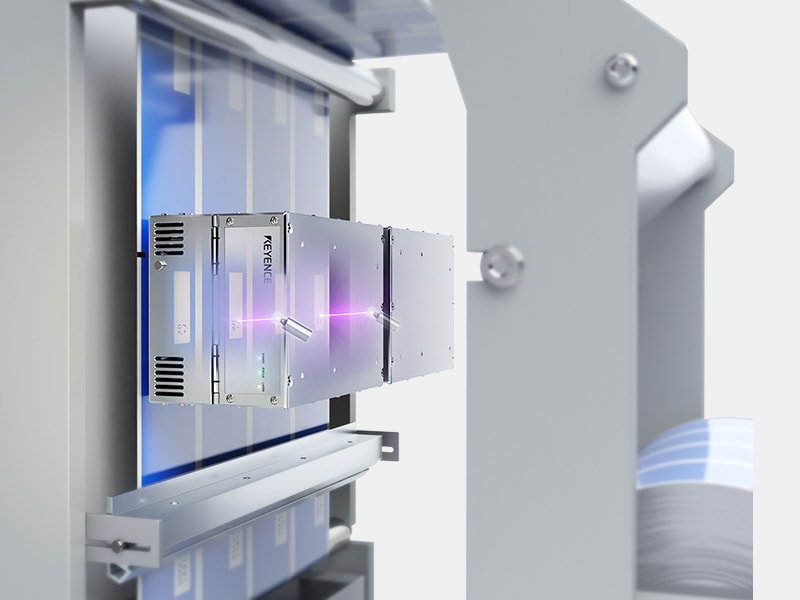

UV Laser Coding for Sachets and Stickpacks: Precision & Efficiency

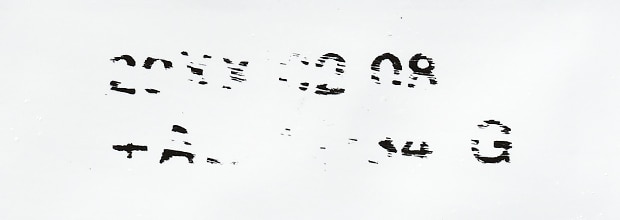

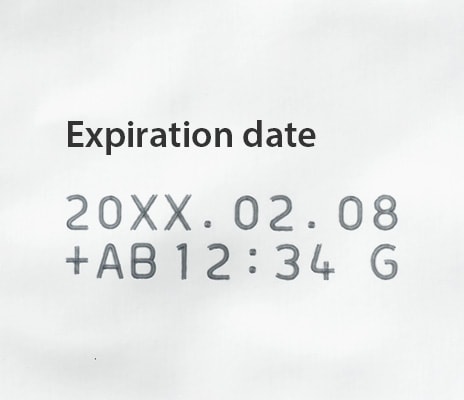

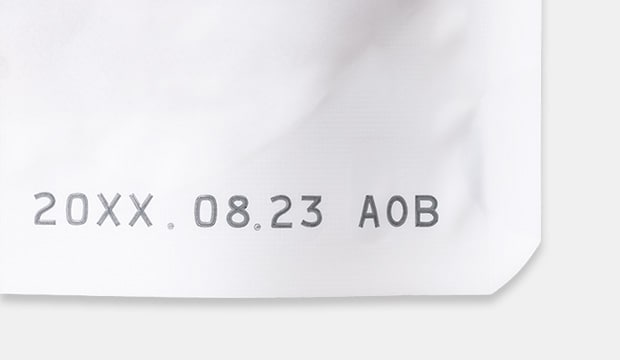

When it comes to packaging products like sachets and stickpacks, manufacturers need to ensure clear, durable, and tamper-proof markings that maintain product integrity and meet regulatory requirements. Traditional methods like thermal transfer overprinting (TTO) and inkjet coding have been used for years for coding expiration dates, batch numbers, and barcodes for sachets and stickpacks, but they often come with challenges like smudging, fading, and wear-and-tear.

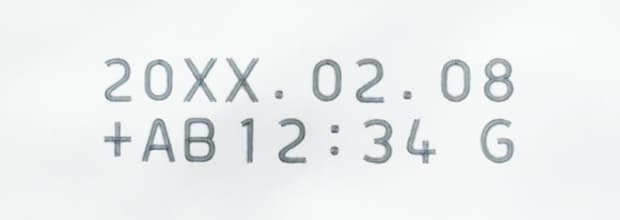

No ink transfer after marking

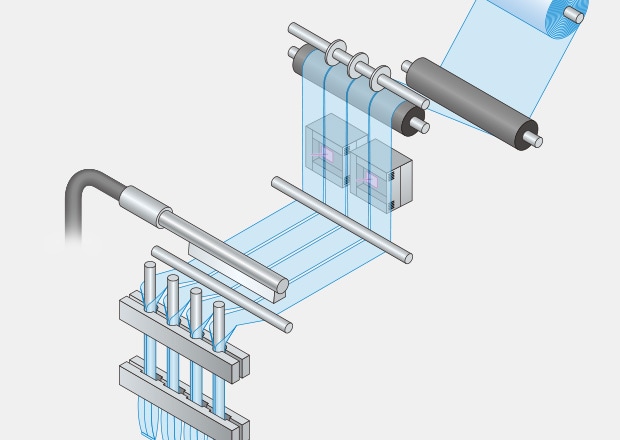

UV laser coders can replace these technologies as they are built to deliver high-precision and permanent marking without damaging packaging materials. Unlike ink-based methods, UV lasers do not rely on direct contact or heat to apply markings. Instead, the printer chemically alters the pigmented layers of the packaging, which produces a high-contract, tamper-proof mark that remains legible even when exposed to moisture or rough handling.

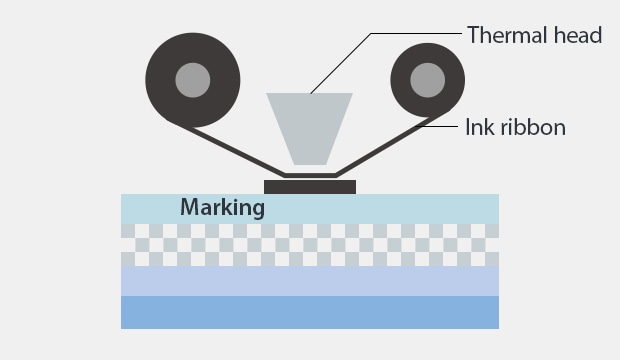

Thermal printers

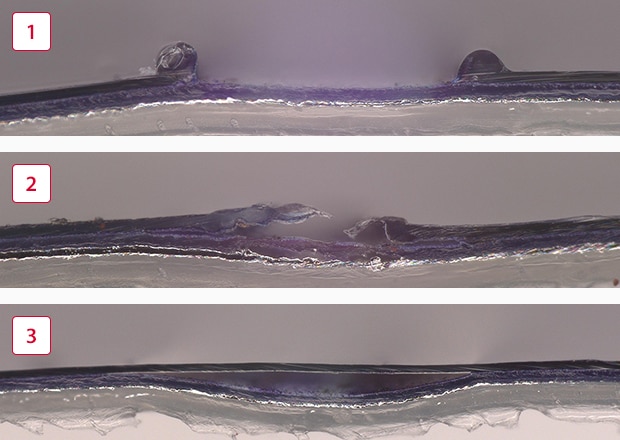

Marking is affected by surface conditions because the ink is transferred onto the film surface.

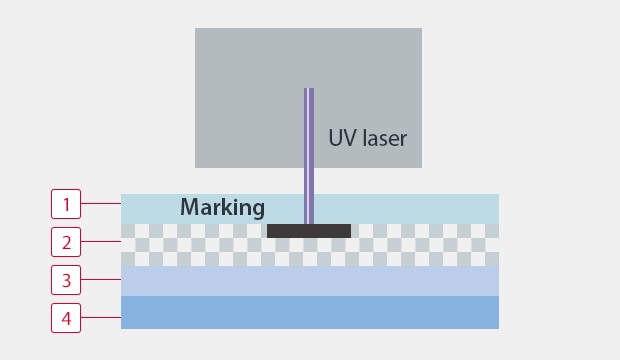

UV laser coders

The marking dose not fade because the color of the marked layer of the film is changed.

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Why UV Laser Coding Is Ideal for Sachets and Stickpacks

UV laser coding is an efficient way to print on small sachets and stickpacks that need to have precise, durable markings:

Permanent, High-Contrast Markings

Sachets and stickpacks are frequently exposed to moisture, friction, and harsh storage conditions, making it essential that codes remain readable throughout the product’s lifecycle. Unlike traditional print methods, UV laser coders create permanent markings that do not degrade over time. When the UV laser chemically alters the pigmented layer of the packaging, it produces a sharp and readable mark that can withstand applications of oils or powders and even heat sterilization.

UV lasers are not affected by traditional causes of marking that fades away:

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

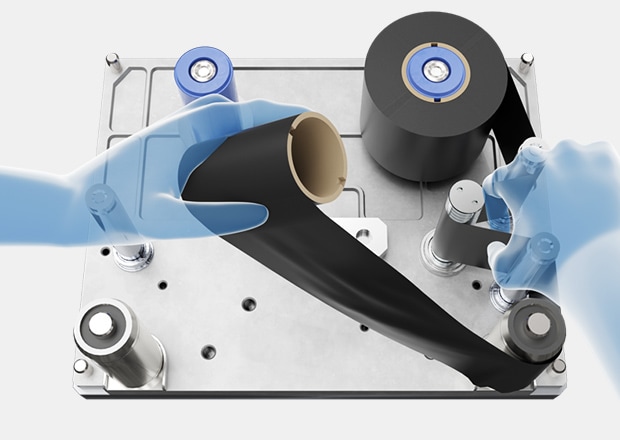

No Consumables

Manufacturers producing sachets and stickpacks daily face high operational costs due to traditional printing systems requiring ink ribbons, solvents, and cartridges, causing recurring expenses and downtime. UV laser coding eliminates consumable dependencies like ink ribbons, solvents, and cartridges, reducing overall operational and environmental costs.

No ink ribbon costs

No head replacement costs

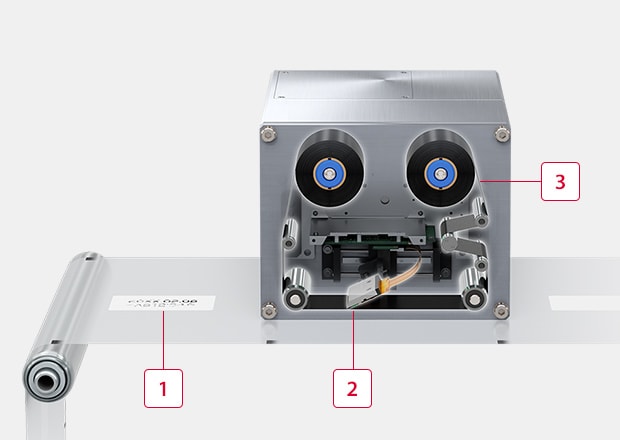

Cross section of marked film

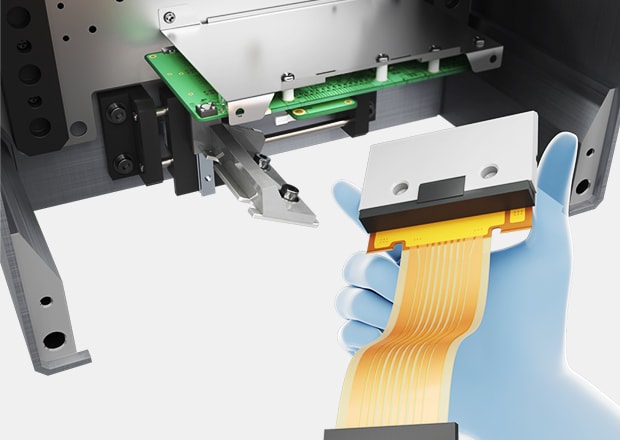

Damage-Free Markings

One of the biggest challenges in coding sachets and stickpacks is that their lightweight, flexible materials are highly susceptible to damage. An issue that arises with CO2 or fiber laser marking on sachets and stickpacks is damage done to the packaging. These lasers produce high heat which can warp or puncture the thin packaging. UV laser coding uses a cold marking process that preserves the materials while applying clear and damage-free codes.

-

1CO2 laser

-

2Fiber laser

-

3UV laser

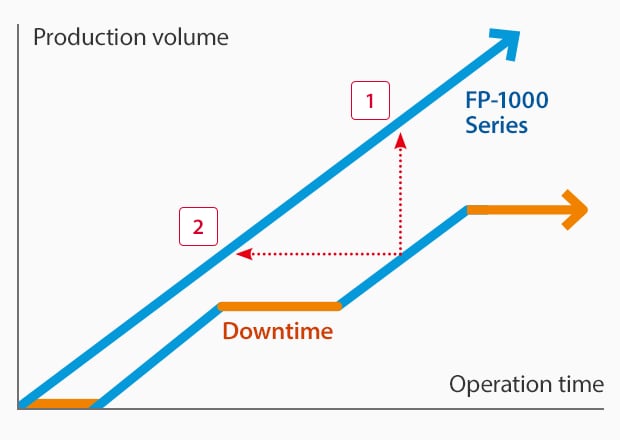

Suitable for High-Speed Production

Sachets and stickpacks are often manufactured at high speeds on rapid production lines, where many traditional printers have a tough time keeping pace. UV laser coders are engineered for efficiency and to deal with fast-moving packaging lines.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Curious about our pricing?

Click here to find out more.

Key Benefits of Using UV Laser Coders for Sachets & Stickpacks

Switching to UV laser coding for sachets and stickpacks offers significant advantages over traditional ink-based systems and eliminates the common limitations of TTO and inkjet methods, including:

- Zero Downtime: UV laser coding has the advantage of not needing to stop production to replace ribbons or printer heads or perform other maintenance tasks. TTO printers require frequent ribbon changes and printhead cleaning, which contributes to costly downtime and lower throughput.

- Reduced Operating Costs: While TTO printers have a lower upfront cost, their reliance on ribbons and part replacements make them very expensive to maintain in the long run. Ribbon replacement not only has a monetary cost but also the cost of downtime to replace each part.

- Superior Readability for Traceability: Regulatory agencies require manufacturers to implement permanent and high-resolution codes of track-and-trace compliance. This way, a product can be identified at every stage of the supply chain, as well as during product recalls.

- Sterile, Contamination-Free Marking: For industries where sterility is a main concern, TTO and inkjet coders can become a major source of contamination, with ink smudges and solvents being top contenders. UV laser coding provides a clean, non-contact process that eliminates the need for materials that would cause contamination.

No periodic parts replacement required

No consumables

No periodic maintenance/inspection required

No faded marking

Discover more about this product.

Click here to book your demo.

Applications in Various Industries

With its non-contact marking process, high-speed performance, and contamination-free operation, UV laser coders are widely adaptable across multiple industries.

In the food and beverage industry, sachets and stickpacks are commonly used for powdered drink mixes, condiments, and single-use coffee and tea pouches; all of which are required by the FDA to be marked with expiration dates and batch numbers. As UV laser coding has a non-contact printing method and can withstand heat sterilization, it is ideal for food-safe applications.

The pharmaceutical and medical industries rely on tamper-proof serialization of UV laser coders to meet strict compliance and anti-counterfeiting requirements. Medical powders and liquid vials must carry accurate, legible information throughout their lifecycle. UV laser coding eliminates the risks of contamination by inks or solvents, which is perfect for cleanliness in sterile manufacturing environments.

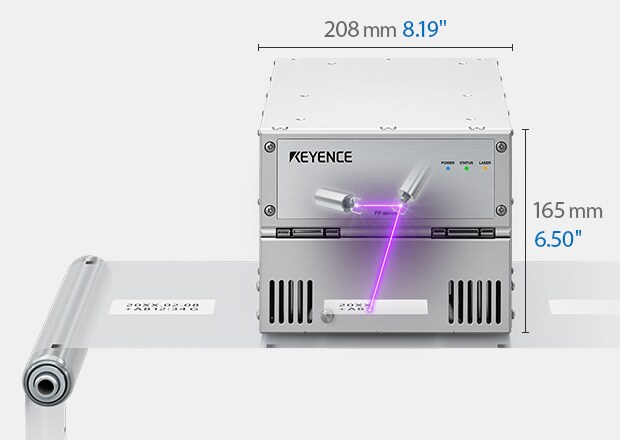

For those looking to improve productivity, KEYENCE offers an alternative to traditional printing methods with the FP-1000 Series UV Laser Coder. The FP-1000 Series is a groundbreaking technology, offering superior efficiency without relying on consumables like ink ribbons.

If you want to shift towards a smarter solution, KEYENCE is here for you. Contact us today.

Conventional thermal printer

-

1Risk of marking that fades

-

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

Replacement of current TTO is simple due to similar outer dimensions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs on UV Laser Coding for Sachets & Stickpacks

Can UV Laser Marking Affect Thin or Flexible Packaging Materials?

No. UV laser coders, like the KEYENCE FP-1000 Series laser coder, use a cold marking process that only alters the internal pigmented layer of material, which preserves the packaging's integrity.

How Do UV Laser Coders Ensure Permanent Marks on Sachets Covered in Liquids or Powders?

UV laser coders do not print using ink, so if a sachet or stickpack is covered in oil, powder, or alcohol, the marking is still permanently affixed to the packaging.

Can UV Laser Coders Handle High-Speed Packaging Lines?

Yes, for example, KEYENCE FP-1000 Series supports 5000 mm/s (196.85″/s) marking speed and a 240 m/min (787.4′/min) line speed, making it perfect for fast-moving production lines.

How Long Does UV Laser Marking Last on Sachets and Stickpacks?

Unlike ink-based systems, UV laser markings are permanent and do not degrade over time. They are also resistant to friction and heat, as well as packaging sterilization.

Is UV Laser Marking Food Safe for Sachets in the Food Industry?

Yes, UV laser coding is a clean, non-contact process that does not use inks, solvents, or other chemicals to make its marks, and it meets strict FDA and global food safety standards.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)