Why Permanent Marking Is Crucial for Film Packaging

Film packaging is a lightweight and cost-effective material that plays a significant role in industries like food and pharmaceuticals. It's also incredibly durable, which makes it perfect for high-speed production. However, as industries demand faster throughput and greater regulatory compliance, the need for high-quality packaging printing has never been more important.

Common Challenges in Marking on Film Materials

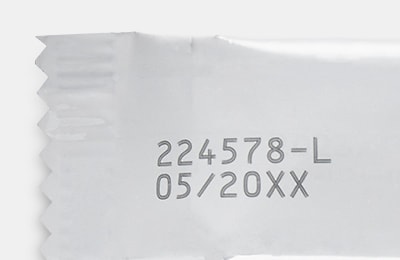

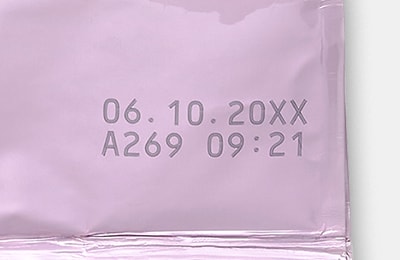

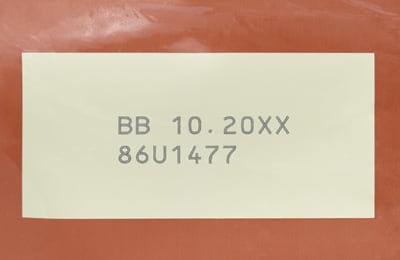

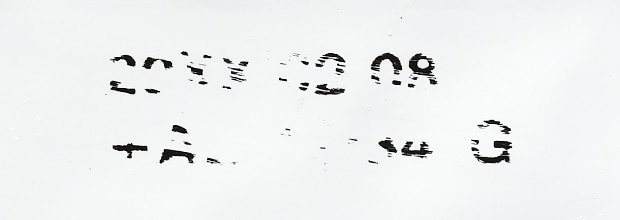

While printing on food packaging and other film-based materials is essential for branding, traceability, and regulatory compliance, traditional methods present several challenges. Ink-based systems, such as thermal transfer overprinters (TTO), rely on consumables that wear out over time, leading to inconsistent prints, smudging, and costly downtime for maintenance. Additionally, environmental factors such as moisture, heat, and chemical exposure can degrade ink-based marks, making date printing on packaging film unreliable in harsh conditions.

In the next sections, we’ll explore the importance of permanent marking in film packaging, the limitations of traditional marking methods, and the advantages of using the KEYENCE FP-1000 Series to achieve permanent marking.

The Importance of Permanent Marking on Film Packaging

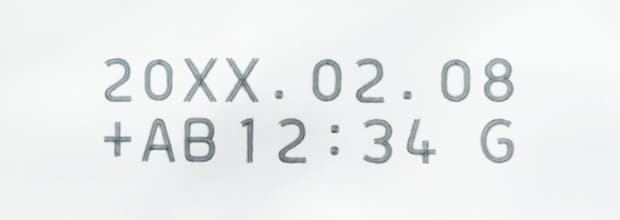

Permanent marking helps keep supply chains organized, especially in food, pharmaceutical, and consumer goods packaging. UV laser coding provides a high-contrast, damage-free solution that makes sure product information remains intact from production to end use. Serialization and barcode marking help manufacturers track shipments, prevent counterfeiting, and enhance consumer safety by enabling accurate recall processes when necessary.

Compliance with Regulatory Standards

Global regulations mandate clear and permanent identification on food, pharmaceutical, and medical packaging to protect consumers. Organizations such as the FDA and EU regulatory bodies require expiration dates, batch numbers, and product origins to be legible and tamper-proof. Unlike ink-based packaging printing, which can fade or be altered, UV laser marking is resistant to oil, powder, alcohol, and heat sterilization, ensuring compliance with even the most stringent industry requirements.

Curious about our pricing?

Click here to find out more.

Limitations of Traditional Marking Methods

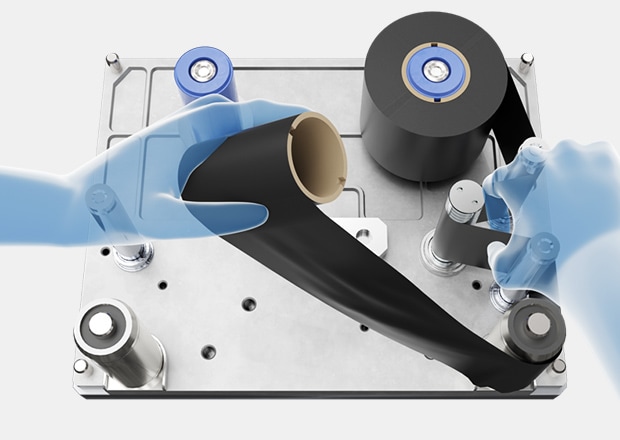

Traditional TTO and inkjet printing require frequent ribbon and ink cartridge replacements, leading to production delays and high consumable costs. They are also not environmentally friendly. The use of ink and ribbons generates a significant amount of waste, which is harmful to the environment. Additionally, these methods may emit volatile organic compounds (VOCs) during the printing process, contributing to air pollution.

No ink ribbon costs

No head replacement costs

Ink-based prints are also prone to smudges and errors, resulting in poor-quality prints. This can be especially problematic when printing on sensitive or irregular surfaces such as packaging materials or textured fabrics.

Advantages of the FP-1000 Series in Achieving Permanent Marks

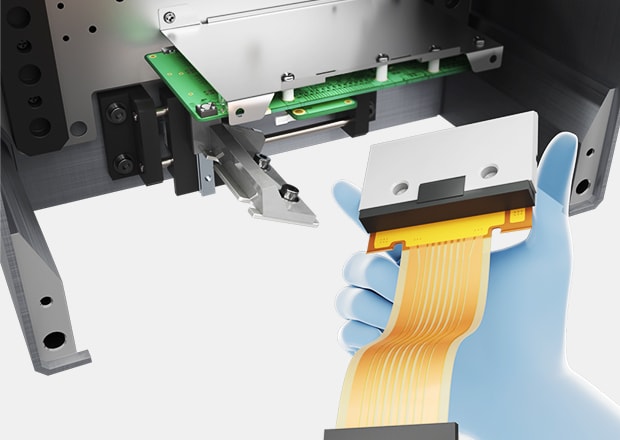

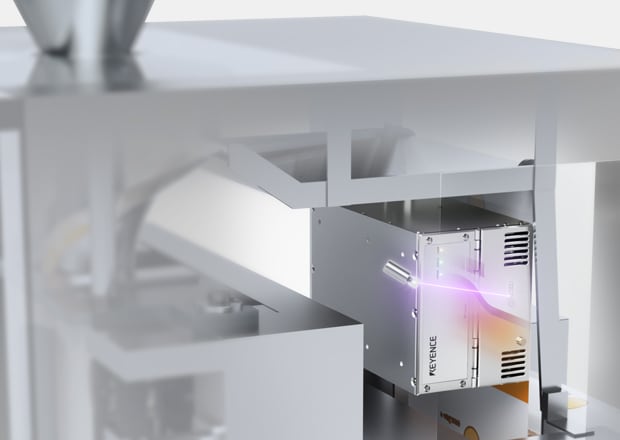

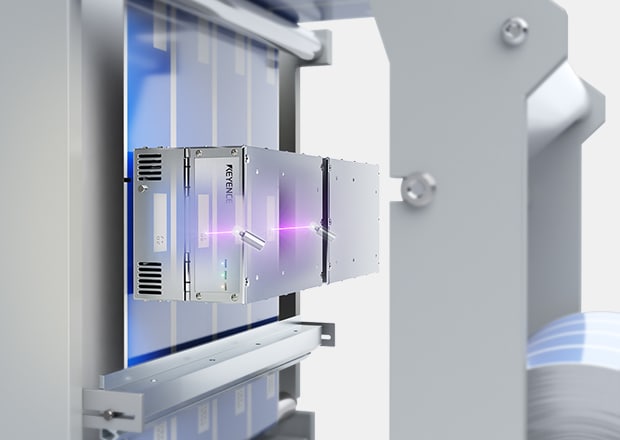

The FP-1000 Series is specifically engineered to provide superior marking performance on flexible film materials. With high-speed marking capabilities, precise resolution, and compatibility with a wide range of substrates, the FP-1000 Series installs directly into existing production lines. Its compact head design allows for easy installation on horizontal and vertical pillow-type packaging machines, bag-feeding systems, and stick packaging lines. This results in many benefits:

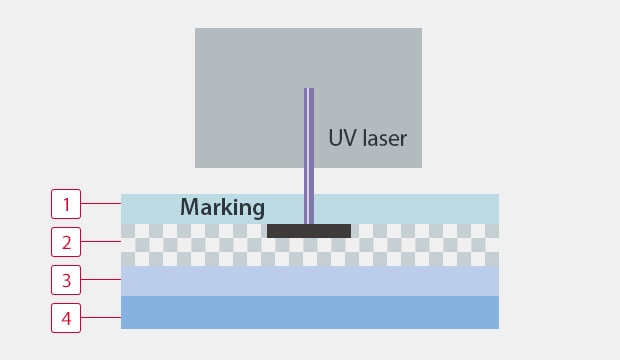

High-Contrast, Damage-Free Marking Without Special Films

Unlike ink-based systems that require pre-treated films or specialized coatings, the FP-1000 Series marks directly on film packaging without altering its structural integrity. Its short-wavelength UV laser interacts with the inner pigmented layer, creating a clear, permanent mark without compromising the protective sealant layers. This results in a high-contrast print that does not fade over time, even under heavy handling and environmental stress.

UV laser coders

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Resistance to Environmental Factors: Oil, Powder, Alcohol, and Heat Sterilization

Many industries require packaging printing that can withstand exposure to oils, powders, and cleaning agents. The FP-1000 Series' laser-marked codes remain readable even after being subjected to extreme conditions, including heat sterilization, alcohol wipes, and friction during transportation. This keeps date printing on packaging film accurate and intact, reducing the risk of product recalls due to illegible markings.

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

Elimination of Consumables: No Ink Ribbons or Print Heads Required

One of the most significant advantages of the FP-1000 Series is its ability to eliminate consumables entirely. Traditional printing on food packaging relies on ink ribbons and print heads that wear out over time, leading to recurring costs and downtime for maintenance. This makes the FP-1000 Series a cost-effective, sustainable alternative that minimizes waste and reduces overall operational expenses.

Discover more about this product.

Click here to book your demo.

Enhancing Production Efficiency with the FP-1000 Series

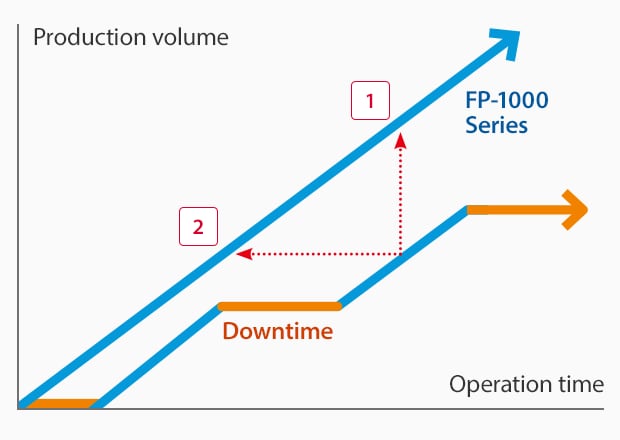

Reduction of Downtime Through Non-Contact, Consumable-Free Operation

With no ink ribbons to replace and no print heads to clean, the FP-1000 Series eliminates the need for routine stoppages, significantly improving Overall Equipment Effectiveness (OEE). Unlike ink-based systems that require frequent maintenance, UV laser marking supports uninterrupted operation, increasing throughput and reducing labor costs associated with printer upkeep.

-

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Seamless Integration with Various Packaging Machines

The FP-1000 Series is designed for easy installation on existing packaging lines. Whether used on horizontal pillow-type machines, vertical bagging systems, or stick pack production lines, its compact design and flexible mounting options allow manufacturers to transition from thermal transfer printers without extensive modifications. The FP-1000 Series’ high-speed capabilities help it keep pace with even the fastest production lines.

User-Friendly Interface Minimizing Operator Error

Equipped with an intuitive touch-panel interface, the FP-1000 Series simplifies programming and operation. Unlike ink-based systems that require skilled technicians for ribbon replacements and print head adjustments, the FP-1000 Series’ software allows operators of all experience levels to configure settings quickly.

Permanent Marking for Reliable and Sustainable Film Packaging

The transition to UV laser marking is a significant step in packaging printing. With the FP-1000 Series, printing on food packaging remains permanent, legible, and cost-efficient while eliminating waste associated with traditional ink-based methods.

The KEYENCE FP-1000 Series UV Laser Coder offers an impressive alternative to traditional ink methods. With consumable-free, high-contrast, and durable prints, it enhances efficiency, traceability, and product quality. A smart, sustainable choice for manufacturers.

Contact KEYENCE today to learn more about the FP-1000 Series and other laser coding solutions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does the FP-1000 Series Ensure Permanent Marks Without Damaging Film Packaging?

The FP-1000 Series utilizes a 355 nm UV laser, which only interacts with the inner pigmented marking layer of multilayered film materials.

Can the FP-1000 Series Be Integrated into Existing Production Lines Without Major Modifications?

Yes, the FP-1000 Series is designed as a direct replacement for TTO and inkjet systems, with compact mounting options that allow for quick installation.

What Types of Film Materials Are Compatible with the FP-1000 Series' UV Laser Marking?

The FP-1000 Series works with various packaging films like polyethylene (PE), polypropylene (PP), and high-density polyethylene (HDPE), plus aluminum-laminated films.

How Does the FP-1000 Series Contribute to Reducing Operational Costs?

The FP-1000 Series eliminates the need for costly ink ribbons, solvents, print heads, and other expenses that add up over time.

Is the FP-1000 Series Suitable for High-Speed Production Environments?

Absolutely, it supports speeds and can even exceed speeds handled by traditional printing equipment.

We’re here to provide you with more details.

Reach out today!

![UV Laser Marker Usage Guide [Food, Pharmaceutical, and Cosmetics Industry Edition]](/img/asset/AS_98694_L.jpg)

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)