2D Vision-Guided Robotics

2D VGR series

2D Vision-Guided Robotics 2D VGR series

New Vision-Guided Robotics With Improved Stability

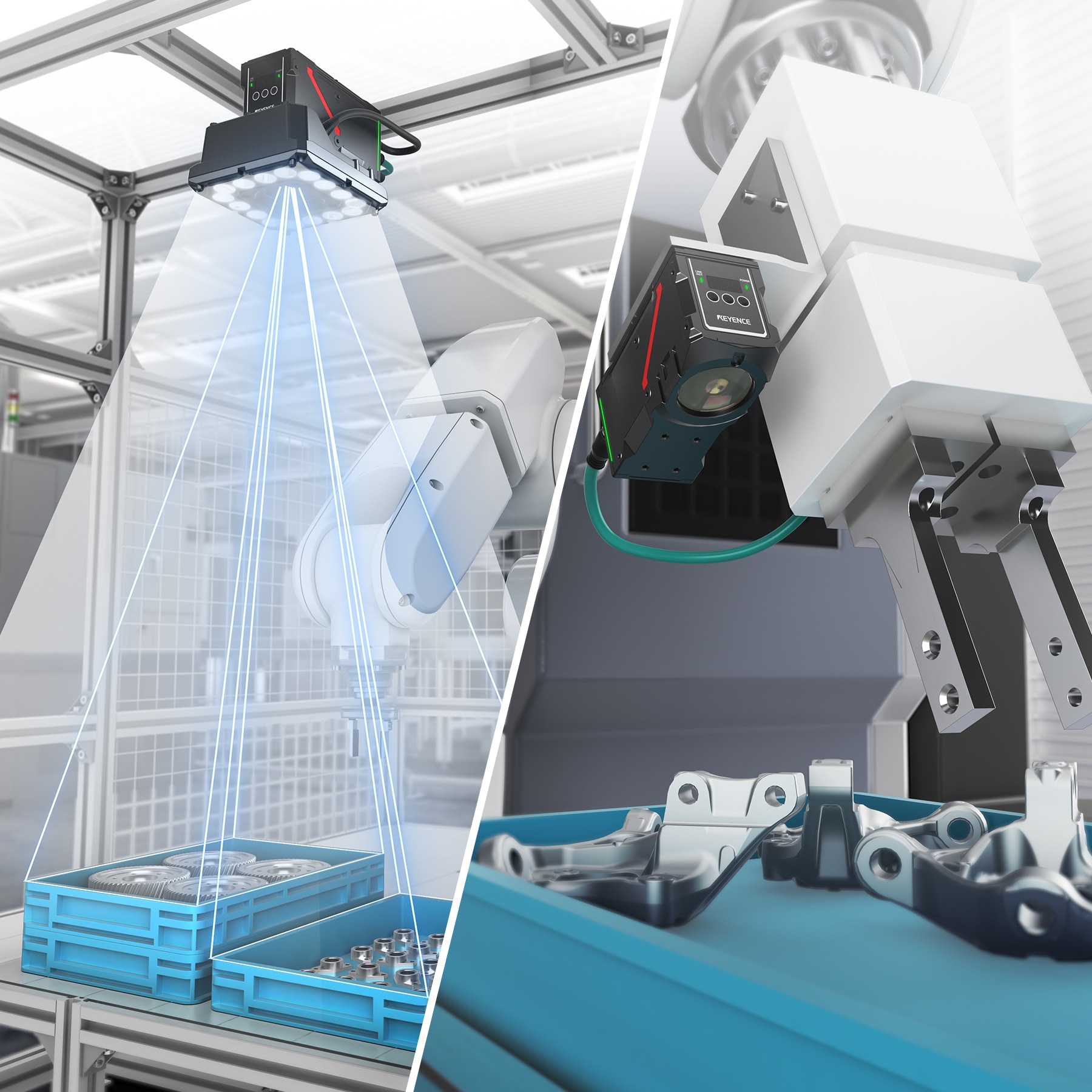

Optimal image creation with vision-guided robotics.

- Bright, uniform illumination even over a wide field of view

- Support for multiple pallets and tooling changeover

- Optimal hardware for on-hand and fixed mount picking

2D vision-guided robotics hardware from KEYENCE has become the global standard when equipping robots for pick & place and grip correction applications. A simplified robot vision interface paired with KEYENCE provided robot programs allows for seamless connection to all major robot manufacturers, including one-click auto-calibration. With industry leading imaging technology and highly-accurate pattern detection tools, these systems are well suited to solve any 2D guidance application.

Features

Bright, Uniform Illumination Even Over a Wide Field of View

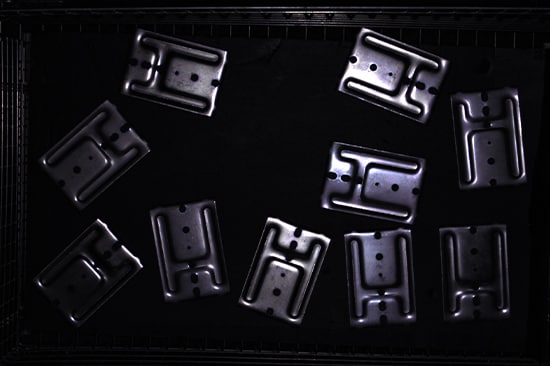

With a wider field of view, brightness can be uneven with a noticeable difference in intensity between the center and the edges of the screen.

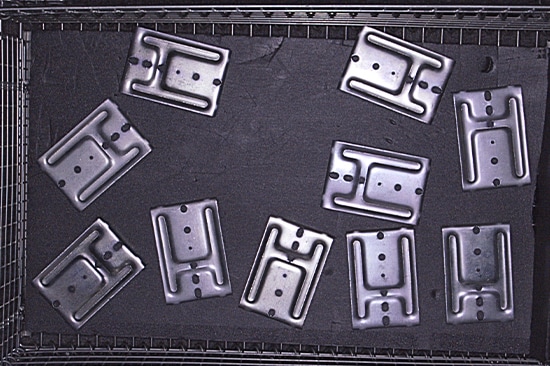

Advanced imaging technologies such as overdrive lighting with high intensity smart ring illumination and HDR capturing help to minimize such differences even with a wide field of view.

Before

After

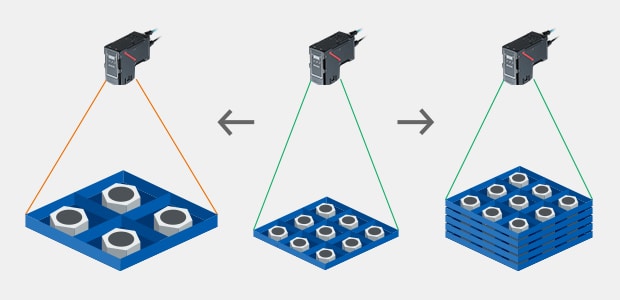

Support for Multiple Pallets and Tooling Changeover

ZoomTrax automatically changes the field of view to suit the size of the target, and automatic focusing makes it possible to handle pallets with different heights, allowing for usability in a wide variety of production environments without changing lenses.

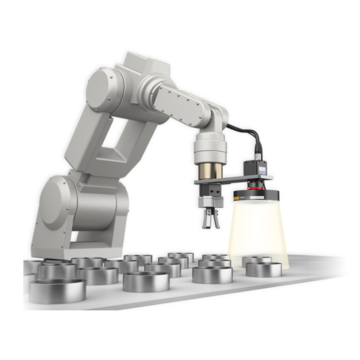

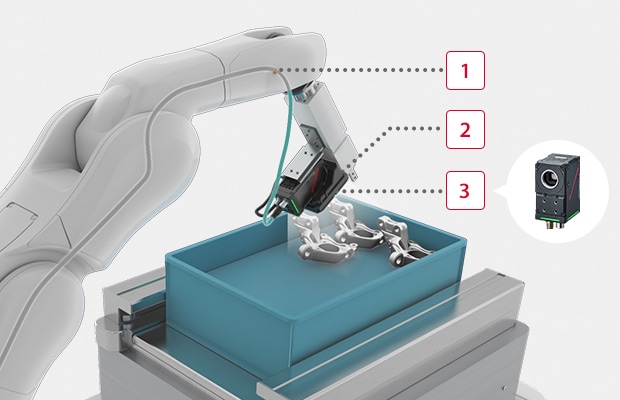

Optimal Hardware for On-Hand Picking

A wider range of on-hand applications is possible thanks to on-robot PoE connectivity, IP67 environmental resistance, and a lightweight C-mount design.

-

1Connects to internal wiring, which prevents cable breakage

-

2Robust IP67 enclosure rating

-

3Lightweight C-mount design option

Outstanding Compatibility With a Wide Variety of Robot Manufacturers

Support for a Wide Variety of Robot Manufacturers

Directly connect to standard robot controllers by selecting the manufacturer name from a list of common robot manufacturers. Take advantage of a single interface for setting up vision-guided robotics even when using different robots for different processes.

| Supported robot manufacturers | |||||||

|---|---|---|---|---|---|---|---|

| Supported robot manufacturers | ABB | ABB | DAIHEN | DENSO | EPSON | FANUC | HIRATA |

| DAIHEN | IAI | JANOME | KAWASAKI | KUKA | MITSUBISHI | NACHI | |

| DENSO | STAUBLI | SHIBAURA MACHINE | UNIVERSAL ROBOTS | YAMAHA | YASKAWA MOTOMAN | Custom | |

| EPSON | |||||||

| FANUC | |||||||

| HIRATA | |||||||

| IAI | |||||||

| JANOME | |||||||

| KAWASAKI | |||||||

| KUKA | |||||||

| MITSUBISHI | |||||||

| NACHI | |||||||

| STAUBLI | |||||||

| SHIBAURA MACHINE | |||||||

| UNIVERSAL ROBOTS | |||||||

| YAMAHA | |||||||

| YASKAWA MOTOMAN | |||||||

| Custom | |||||||

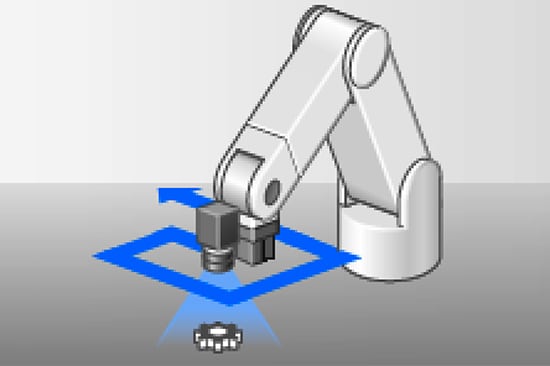

Fast and Accurate Calibration for All Users

Auto-Calibration

Time-consuming calibration can be automatically completed with a single click, ensuring the same accuracy and startup stability for all users.

Before

Conventional problems

- Accuracy varies between operators

- Difficult to readjust for installation misalignment

- Difficult to reproduce the image in different installation locations due to variations in ambient conditions

After

Solutions provided with KEYENCE vision-guided robotics

- High accuracy regardless of operator

- Quick calibration to fix issues caused by misalignment

- Easy operation with a single click jogging robot to all required locations

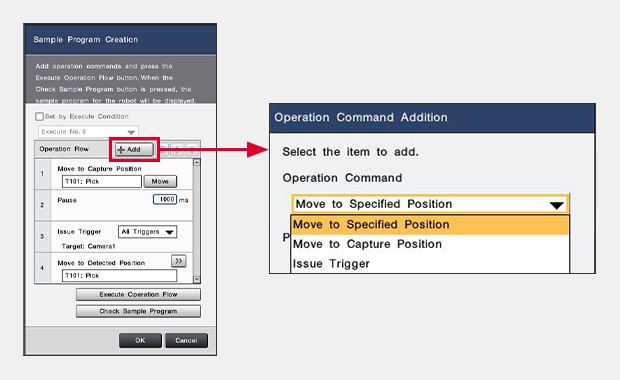

Simplified Robot Operation Support

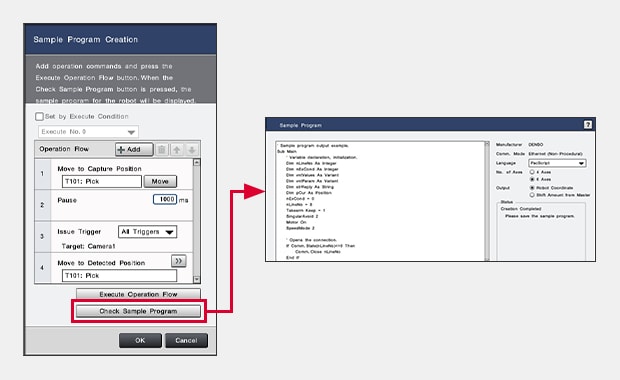

Robot programs can be created automatically and easily by specifying the operation flow.

Easy configuration just by choosing the desired robot operation.

Robot manufacturer–specific programming languages.

Powerful Search Tools for Impressive Performance, Speed, and Accuracy

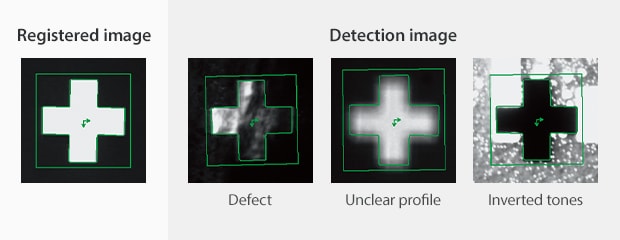

Enjoy stable position detection only available from an experienced vision system manufacturer!

Enables accurate searching even if capture conditions change from those of the registered image.

Various Simultaneous Inspections

Add other inspections as needed, including character recognition, appearance inspection, and product type differentiation.

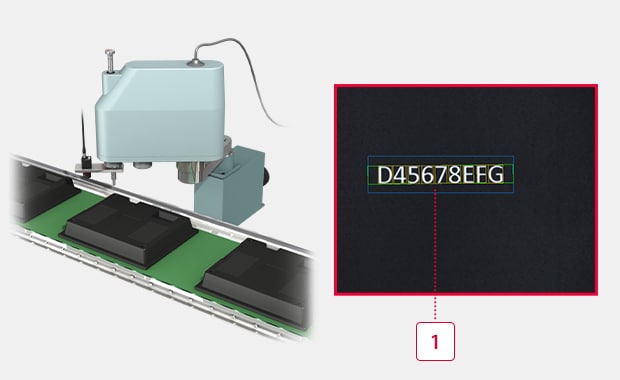

Identification Inspection (OCR, 1D/2D Codes)

Position detection and character reading are performed at the same time.

-

1Character recognition

Appearance Inspection

After picking, products are inspected and rejected if defects are found.

-

1Surface defect