- Home

- Solutions

- Case Studies

- KEYENCE safety light curtains boost productivity and efficiency at Bosch

KEYENCE safety light curtains boost productivity and efficiency at Bosch

The KEYENCE GL-R series of light curtains were designed with a rough and demanding manufacturing process in mind. The GL-R features a thick aluminum housing along with a recessed lens face protecting it from drop, shock, and direct impact. Furthermore, the durability of the GL-R series greatly reduces the risk of machine downtime. Samuel Martínez, a maintenance engineer at Bosch, explained why the company installed the GL-R series on its production line after realizing a machine’s cycle time was much longer than necessary.

The machine in question installs needle bearings onto an engine shaft. This station verifies a number of characteristics in the assembly process and once completed, continues down the production line.

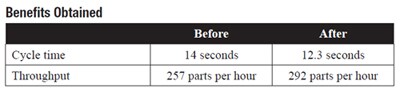

“We installed safety light curtains on this machine because it had one of the highest cycle times in the plant which was causing production bottlenecks. It was imperative to reduce the cycle time of the entire production line, not to mention improving safety for the system operator,” explained Mr. Martínez.

“The line should have been taking 12 seconds to produce one part, but the machines were taking much longer. The old solution was a physical guard that took 2 additional seconds to cycle. That is why we had to find an alternative.”

Safety curtains allow operators unobstructed access without sacrificing safety. Once the light curtain is interrupted (i.e. by a person or an object), it will automatically stop the machine. “Compared to the old system, where the operator had to wait until the door closed completely before starting the cycle, the benefits are clear”.

While the Bosch Toluca plant also uses curtains made by other suppliers, Mr. Martínez noted that the difference with the KEYENCE curtains is their durability. “Although KEYENCE safety curtains operate basically like other safety curtains, we chose KEYENCE because it has a line that is suitable for heavy-duty environments. This means that we can guarantee if our operators hit, scrape, or even spill something on the curtains, they do not need to worry about causing damage and can continue working undisturbed.”

Another area of value is the service and technical support provided by a local KEYENCE specialist whenever requested. KEYENCE safety specialists offer detailed information, advice and solutions for any type of application to ensure the equipment is used in the safest and most efficient manner.

In summary, by implementing the KEYENCE GL-R series, Bosch was able to improve production efficiency while not sacrificing safety.

APPLICABLE PRODUCT CATALOG

- GL-R Series Safety Light Curtain Catalog

This series is durable and simple. High power, recessed lens, and an extruded aluminum frame eliminate nuisance trips and offer sustained protection. Easy integration with full length indicators, built-in alignment, and multiple wiring options

Related Products

-

- Safety Light Curtain

GL-R series -

This series is durable and simple. High power, recessed lens, and an extruded aluminum frame eliminate nuisance trips and offer sustained protection. Easy integration with full length indicators, built-in alignment, and multiple wiring options.

- Safety Light Curtain

- PLEASE

CONTACT US