PLC-linked Applications: Clamp-on Flow Sensor

Quality Management with Centralized Flow Rate Monitoring

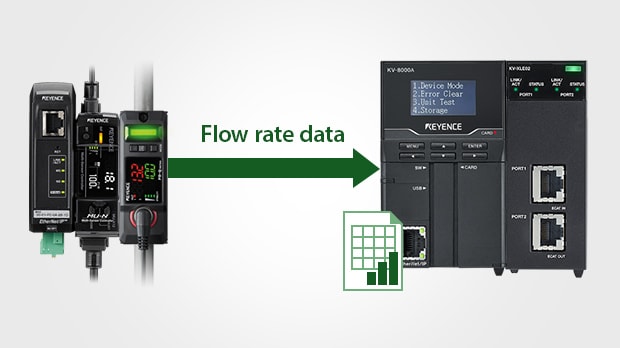

Simultaneous monitoring of multiple flow sensors is possible from the PLC. The ability to monitor sudden or gradual changes in flow rate from a central point helps improve quality control and energy savings.

Symptom Monitoring with Flow Rate Logging

Logging the flow rate data makes it possible to monitor for signs of quality issues due to variations in the flow rate or equipment malfunctions caused by insufficient coolant.

Flow Rate Visualization for Increased Energy Savings

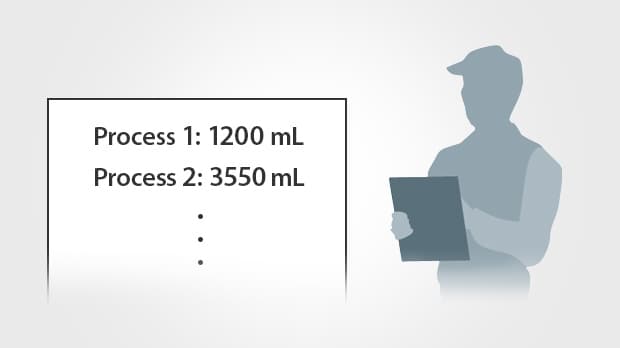

Daily usages can be visualized by monitoring the accumulated flow rates for each process using the PLC, which can help save energy. This also eliminates the need to visually check and record daily flow rates.

Related Downloads

This is a collection of examples of connecting sensor networks without using ladder programs.

Compatible with a variety of pipe materials and liquids, the FD-Q series can detect the flow rate of a liquid without the need for any pipe modification. This eliminates the risk of leakage and pressure loss. Liquids include water (and pure water), oil, and chemicals. Detect on both metal and resin pipes up to 2" in diameter.