Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Packaging and Logistics Industry

Nearly everything conceivable nowadays comes in a package, from consumer goods to pharmaceuticals to produce. Consumer-packaged goods must be adequately packed to ensure their quality and safety. As a result, packaging inspection has become a crucial part of manufacturing.

KEYENCE is the world's leading provider of precision technologies and a reliable partner to thousands of packaging companies worldwide, who rely on our sensors for quality assurance and quality control.

Choose Case of Measurement Sensors for the Packaging and Logistics Industry

What Sensors Are Used in the Packaging Industry?

Modern production lines are fast-paced environments, with thousands upon thousands of products being packaged every minute to meet consumer demands. Manually inspecting packages at such a high speed isn't just impractical… it's borderline impossible.

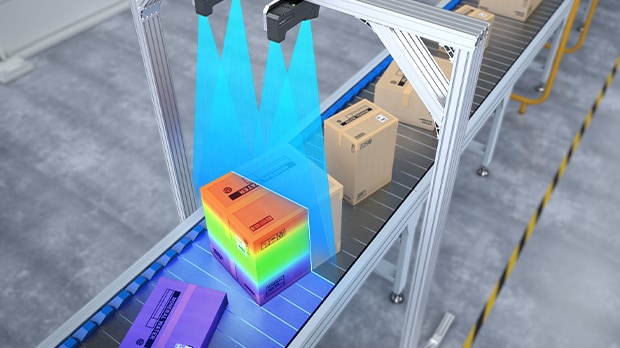

Accurate precision is very important in the packaging industry to ensure products are well packaged and meet quality standards. One of the most advanced technologies transforming this segment is the implementation of 3D laser snapshot sensors for the packaging industry, which provide accurate, non-contact measurement capabilities tailored for packaging applications. These sensors use laser and 3D imaging to capture high-resolution data on dimensions, surface texture, and volume. This is all completed in an instant, making them ideal for high-speed environments where every millisecond counts.

That's why many industries use laser displacement sensors and optical micrometers for packaging inspection. These sensors can check for defects and also measure color, product type, presence, quality, appearance and dimensions.

For example, KEYENCE's LJ-X8000 Series laser profiler can be used to detect the number of products being packaged, the amount of unused space inside a box, and how much cushioning material is needed. Its large depth of field allows for stable measurements, even with different box sizes and content heights. This feature is especially useful when products of various shapes and sizes need to be packed efficiently and securely.

Furthermore, the LJ-X8000 Series can also be used for pallet scanning to obtain accurate position coordinates. This ensures safe handling when lifting boxes from a loaded pallet, preventing any potential accidents or product damage. With its stable measurement capabilities, the LJ-X8000 Series can accurately detect targets with any surface condition, making it an ideal solution for a wide range of packaging applications. In addition to detecting alignment, this type of package inspection sensor can also detect peeling labels and other appearance defects, all of which are inspected simultaneously.

Get detailed information on our products by downloading our catalog.

View Catalog

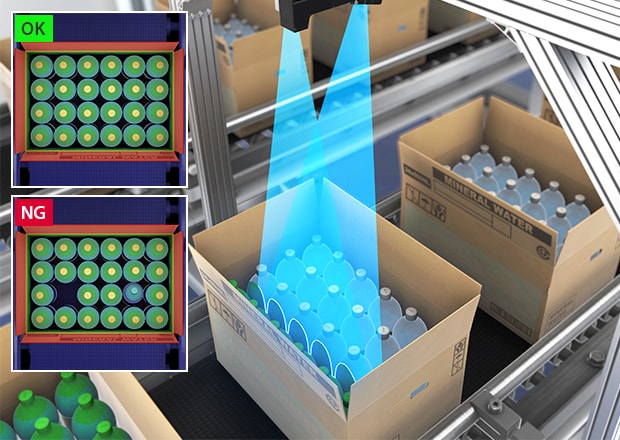

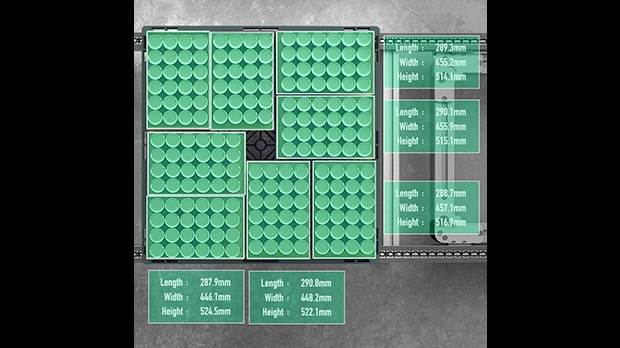

Beverage Bottle Counting

The LJ-X8000 Series can be used to count the number of products being packaged. Acquiring height data makes it possible to detect packaging conditions such as whether different capacity bottles are being packed and if the bottles are buckling.

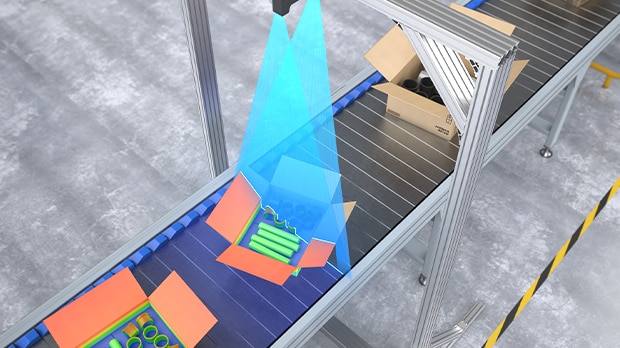

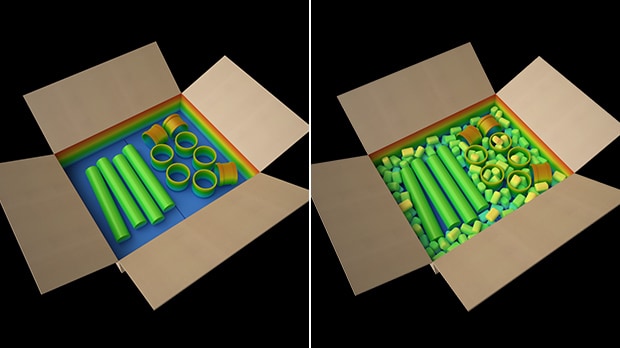

Void Filling/Cushion Placement

The LJ-X8000 Series measures the unused space inside a cardboard box and automatically calculates the amount of cushioning material needed. The large depth of field allows for stable acquisition of empty spaces even with different box sizes and content heights.

Picking and Placing

With the LJ-X8000 Series, measurement using height data is possible regardless of surface conditions, package color, or package orientation.

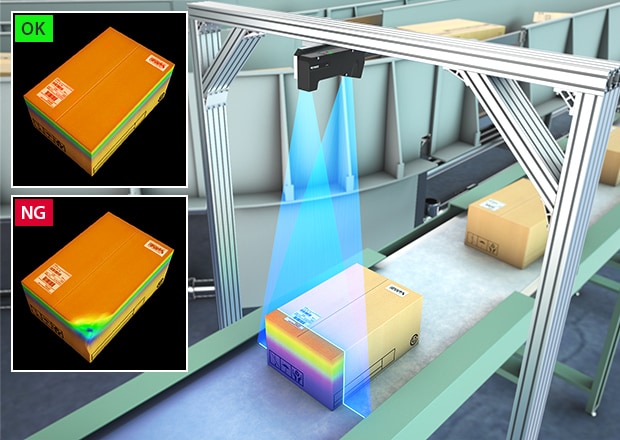

External Appearance Inspection of Cardboard Boxes

Automatic inspection for gaps and dents in boxes is possible with the LJ-X8000 Series. Imaging is stable even if the box includes tape or multiple materials and colors. The LJ-X8000 Series is also not affected by ambient light so countermeasures for lighting are not required.

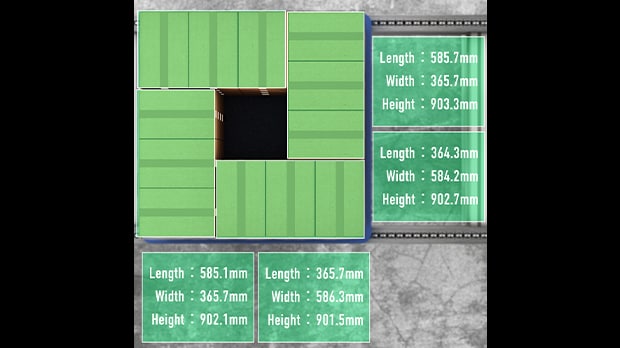

Package Dimension Measurement/Sorting

The LJ-X8000 Series uses 3D data to measure package dimensions, and the results can then be used for sorting. Stable detection is possible with no adverse effects from ambient light or package shape.

Shipping Label Positioning

When applying shipping labels, the labels must be applied in a location free of any other labels. By acquiring a grayscale image of the package, the LJ-X8000 Series can determine the appropriate location for labels while also measuring the dimensions of the package.

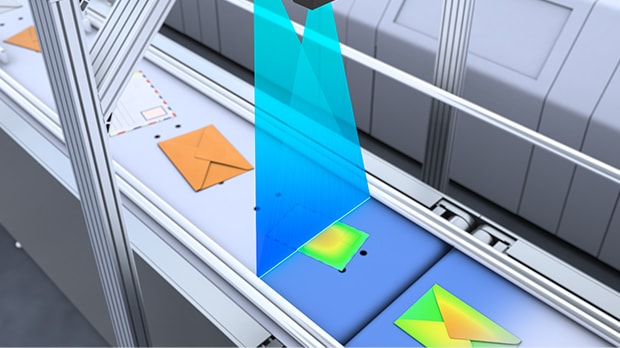

Envelope Sorting

The LJ Series can also be used to sort mail. Thanks to a fast 16 kHz sampling rate, stable size and thickness measurement are possible even when sorting mail at high speeds, helping to automate processes.

Palletizing

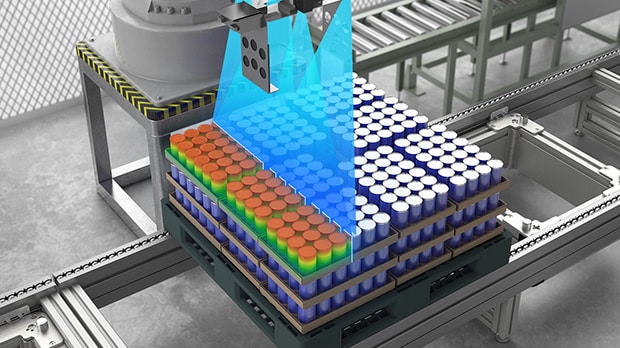

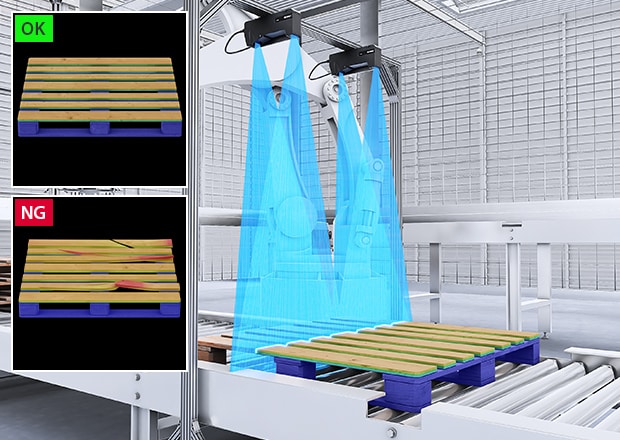

The LJ-X8000 Series makes palletizing packages for loading into large shipping containers easy. During robot-based placing, acquired measurement and 3D shape data allow for safe and accurate palletizing.

Depalletizing

Loaded pallets can also be automatically scanned to obtain accurate position coordinates to ensure safety when lifting boxes from the pallet.

Pallet Inspection

The LJ-X8000 Series can be used to inspect wooden pallets used to store and move products. Inspecting pallets before palletizing makes it possible to prevent damage to products by identifying any damage or stains on pallets that have been used repeatedly.

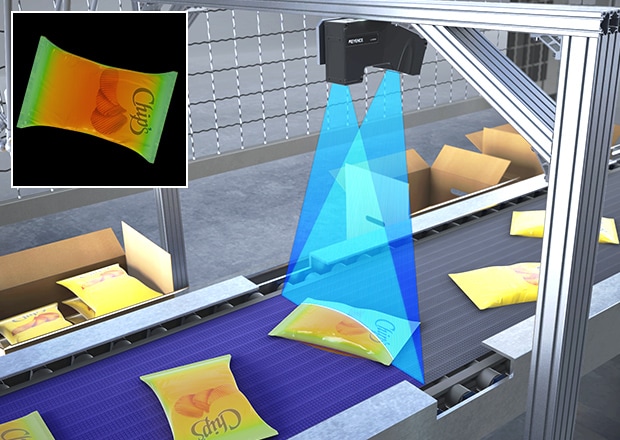

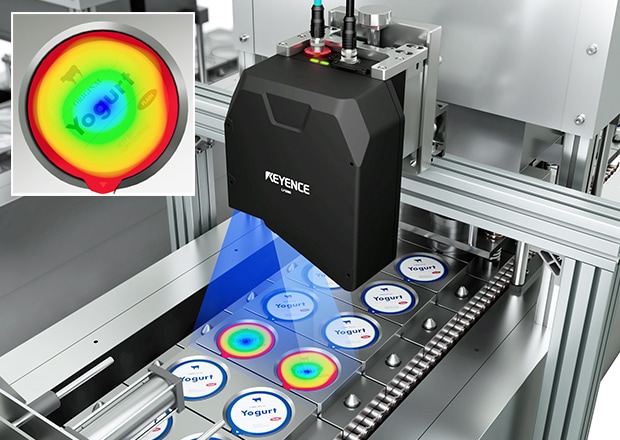

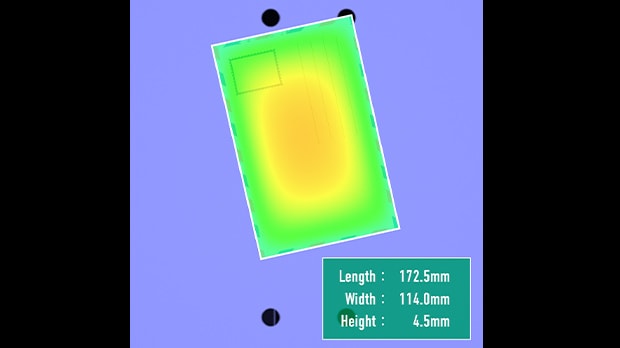

Lid Heat Seal Inspection

A proper heat seal is not only important to the container integrity but also to the overall freshness of whatever is inside the container. The LJ-S8000 Series 3D Laser Profilers can ensure that the heat seal is applied correctly to each container.

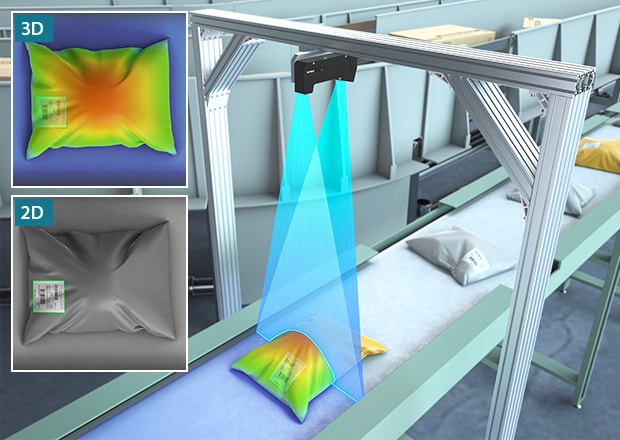

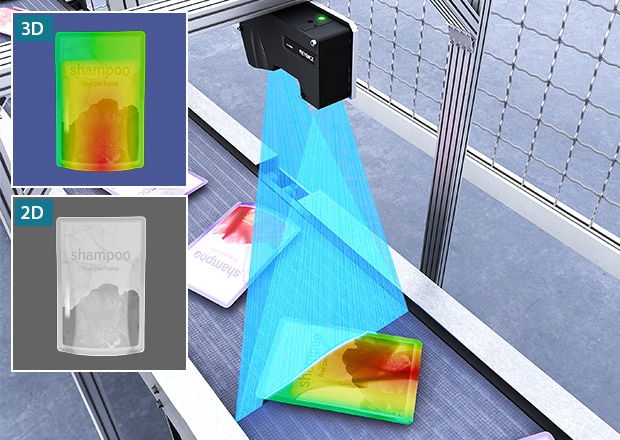

Position Adjustment During Boxing

When products are packed in aluminum pouches, the position information for each pouch must be sent to the packaging robot. Using 3D information makes it possible to determine the actual position of targets based on differences in height that cannot be seen with a 2D image.

Applications and Examples

Precision and Quality Control in Building Material Manufacturing with 3D Snapshot Sensors

When dealing with building materials where accuracy impacts safety and durability, precision and quality control are essential. One solution that has become prominent is the use of 3D snapshot sensors, which offer rapid, high-resolution imaging of various materials.

These sensors use laser or structured light technology to generate detailed, three-dimensional surface profiles, allowing manufacturers to inspect dimensions, detect defects, and ensure material conformity to strict standards. By capturing an entire surface in a single shot, 3D snapshot sensors for the packaging industry expedite the inspection process and maintain production line efficiency without compromising accuracy.

Industrial Snapshot Sensors: Enhancing Building Material Inspections

For building material inspections, industrial snapshot sensors in the packaging industry play a critical role. By integrating 3D laser and 2D imaging, these sensors offer a quick and complete assessment of materials and packages in motion, ensuring they meet all required specifications. These industrial sensors can detect material irregularities, verify packages, and confirm that all parts are within acceptance. This reduces waste and reworks by identifying issues early in the process, reducing costs, and enhancing proficiency.

Advantages of Using Inspection Sensors for the Packaging Industry

Implementing KEYENCE’s package inspection sensors and laser profilers into packaging lines enables continuous and precise monitoring, significantly reducing the risk of products with defective packaging reaching end consumers. Here are other advantages of using KEYENCE’s inspection sensors for the packaging industry:

Efficiency

Sensor solutions for the packaging industry significantly speed up the production process and increase your product output, since they nearly eliminate the need for manual inspection.

Early Defect Detection

Package inspection sensors enable early defect detection, which minimizes material waste and reduces the need for rework. They also prevent defective products from moving forward through the production process.

Effective Maintenance

Early defect detection could indicate a problem in the production line itself, leading to a faster resolution and preventive maintenance.

Quality Assurance

The continuous and precise monitoring provided by KEYENCE equipment minimizes the risk of defective products leaving the factory, thus maintaining product quality.

Regulatory Compliance

Package inspection sensors help the packaging industry maintain compliance with stringent industry regulations, ensuring product quality and recording detailed, accurate data for further review if necessary.

Enhancing Packaging Efficiency with LJ-S8000 Series 3D Laser Snapshot Sensors

3D laser snapshot sensors for the packaging industry are essential in delivering solutions tailored to the building material industry's unique demands. They provide real-time, accurate data that supports automated inspection systems, ensuring that every material package aligns with predefined standards. With these cutting-edge sensor solutions, the packaging industry is seeing unparalleled advancements in efficiency, quality, and operational control.

LJ-S8000 Series snapshot sensors in the packaging industry stand out for their ability to significantly increase quality control processes. These sensors are multipurpose and can be configured for various applications, from verifying package seals and fill levels to checking label alignment and surface consistency. This adaptability makes them a valuable asset for companies seeking to optimize their production lines.

KEYENCE is the world's leading provider of cutting-edge precision technologies often used for industry-specific applications, ranging from manufacturing, medical, food and beverage, and cosmetic industries to industrial process control.

If your organization is looking to enhance your packaging inspection capabilities without package inspection sensors, don't hesitate to contact KEYENCE and inquire about possible integrations of our equipment with your existing production line.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity

![Automated Measurement and Inspection Examples [Food and Containers]](/img/asset/AS_138240_L.jpg)