Measurement Sensors

Dimension Measurement

Displacement Measurement

Meandering/Edge Measurement

When looking for the best way to measure meandering/edge, there are a number of important factors to consider, including the type of measurement system and the installation environment. Selecting equipment that doesn't adequately meet your needs can lead to insufficient precision and increased man-hours during production, so choosing the right equipment is important. This site is designed to help you discover the best way to perform meandering/edge measurement with confidence.

Choose Case of Meandering/Edge Measurement

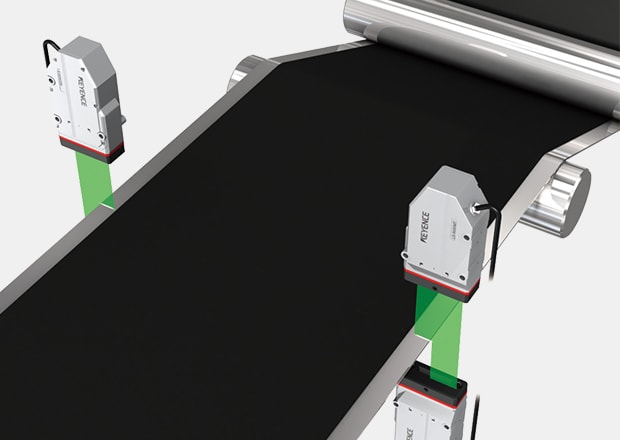

Meandering and Edge Position Measurement with a Thrubeam-Type Sensor

Edge position and target fluctuations are measured for objects within the beam.

The detection threshold can be manually adjusted to allow for stable measurements even for transparent targets.

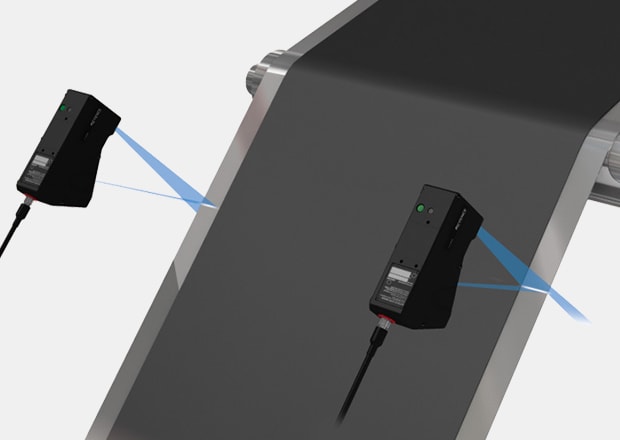

Meandering and Edge Position Measurement with a Reflectance-Type Sensor

The laser line reflects off the target creating a profile from which the edge position fluctuations can be measured. This measurement can be taken from above or the side of the target.

- Edge position variation and height fluctuations can be measured simultaneously.

- Edge meandering can be monitored from a distance.

Edge Measurement Sensors

There are different types of edge measurement sensors. From thrubeam systems to 2D laser profilers, choosing the right one greatly depends on your application.

When it comes to measuring the edges of transparent objects, a thrubeam micrometer (like KEYENCE’s LS-9000 Series) offers exceptionally precise edge and meandering measurements.

Problems with Conventional Systems

Conventional edge measurement systems have issues with their internal structure and operating principles. In conventional edge measuring tools, a laser is fired at a rotating polygonal mirror, which then scans through the measurement range. Measured values are then calculated by how long the laser was obstructed by a target.

This technology is quite limited and susceptible to error due to several reasons. In most cases, the sampling rates are exceptionally low (usually ranging around 1,200Hz). Conventional systems are also unable to tell if a target is tilted, as they’re limited to a single source of measuring data.

Finally, the moving parts within the system tend to deteriorate. Regular calibration of the polygonal mirror and the laser is needed in order to maintain production.

Discover more about this product.

Click here to book your demo.

Benefits of a KEYENCE System

Fortunately, KEYENCE’s edge measurement and edge detection system — particularly the LS-9000 — is specifically designed to overcome the limitations associated with conventional systems and offer several additional benefits. The system relies on a high-intensity green LED, which focuses through a lens to create an evenly distributed high-intensity light beam.

That beam is directed to three distinct CMOS sensors that measure the inclination (which automatically corrects tilt errors), the position between the transmitter and the receivers, and the shape of an object.

Fastest in its Class

The LS-9000 Series has a sampling rate of up to 16,000Hz, which far exceeds conventional systems. This significantly improves cycle times and ensures more stable measurements.

Tilt and Vibration Correction

The CMOS sensors are capable of clearly recognizing measurement targets that suddenly move due to vibration and correcting those measurement errors. The 3-CMOS measurement system integrates several measurements into one.

The Monitor CMOS recognizes the misalignments of the workpiece from the captured image. The inclination error is removed automatically so that it doesn’t affect the measurement results.

Target Positioning

The third CMOS sensor determines the location of the measurement in two axes, enabling the LS-9000 to determine the position of the target in the X-Y range and making the part position feedback much simpler.

Sturdy Construction

The outer housing of the LS-9000 model is made from die-cast material and has been mechanically isolated from the internal optical unit. This means that all shocks and thermal variations are absorbed by the housing, protecting the optics inside. The main system enclosure maintains an IP67 rating.

If you’re looking to upgrade your meandering and edge measurement sensors, KEYENCE offers a wide range of products from categories of laser displacement sensors, 2D laser profilers, and through-beam laser micrometers. If you have any additional questions regarding the integration of KEYENCE equipment into your own manufacturing line, don’t hesitate to contact us.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity