Digital Microscopes

Observation and Measurement of Coatings with a Digital Microscope

Coatings are utilized across various industries, but in the automotive and aerospace sectors, they provide effects such as increased material strength and added functionality. However, maximizing these effects hinges on selecting the optimal coating and application method for the target object and its purpose. This document introduces the purposes and roles of coatings, their application methods, and case studies of analysis using a digital microscope to verify their effectiveness.

Get detailed information on our products by downloading our catalog.

View Catalog

Purpose of Use and Primary Targets for Coatings

| Purpose | Primary Target | Deterioration Factor |

|---|---|---|

|

Purpose

Corrosion Resistance

|

Primary Target

Mainly metals

|

Deterioration Factor

Oxygen, Water

|

|

Purpose

Weather Resistance

|

Primary Target

Mainly plastics

|

Deterioration Factor

Ultraviolet (UV) rays

|

|

Purpose

Decorative Properties

|

Primary Target

All materials

|

Deterioration Factor

-

|

To add strength, it is crucial to clarify the purpose of the coating for the specific target object.

Roles of Coatings

| Characteristic | Content |

|---|---|

|

Characteristic

Mechanical Properties

|

Content

Provides durability, lubrication/anti-slip properties.

|

|

Characteristic

Separation Properties

|

Content

Provides waterproof, gas barrier properties.

|

|

Characteristic

Coating Properties

|

Content

Provides adhesive, water-repellent, antibacterial properties.

|

|

Characteristic

Heat Resistance Properties

|

Content

Provides heat resistance.

|

To add functionality, it is essential to select a coating with the necessary characteristics.

We’re here to provide you with more details.

Reach out today!

Coating Methods

| Coating Method | Precision | Skill Dependency |

|---|---|---|

|

Coating Method

Brush/Roller Coating

|

Precision

Low

|

Skill Dependency

High

|

|

Coating Method

Dip Coating

|

Precision

Low

|

Skill Dependency

High

|

|

Coating Method

Electrodeposition Coating

|

Precision

High

|

Skill Dependency

Low

|

|

Coating Method

Atomization (Spray) Coating

|

Precision

High

|

Skill Dependency

High

|

Select the optimal coating method based on the target object and the type of coating.

Observation and Measurement Case Studies with a Digital Microscope

Even after going through these processes, it is not always clear if the coating has been applied correctly. Below are analysis examples of coating conditions.

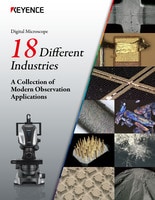

Observation of Coated Surface

Conventional Observation

Observation using Advanced Surface View

Observation of Coating Film

Conventional Observation

Surface Observation using Deep Contrast

Analysis of Foreign Matter in Coating

Bright-field, dark-field, 3D display, and elemental analysis can be performed on a single screen, allowing for the exploration of problem causes from various information.

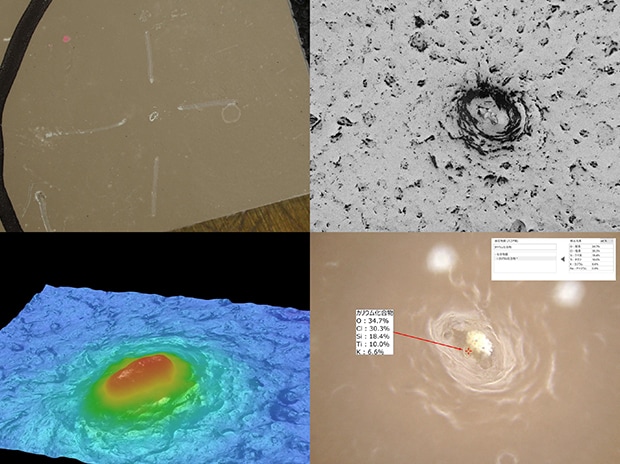

Area Measurement of Coating Film Particles

Instantly performs quantitative analysis of counts that often vary by operator, and facilitates reporting.