Digital Microscopes

Observation and Analysis of Sand Casting

Casting is a processing method in which metallic materials are melted, poured into molds, and then hardened into target shapes as they cool. This section introduces examples of observation and analysis of sand casting.

Typical Casting Methods

Typical casting methods include the following.

Sand casting

Mold type: Sand

The oldest casting method. Melted metal is poured into a sand mold. Molds can only be used once but the cost to make them is low, so this method is suitable for small lot production. The surfaces of parts made with sand molds are rough because of the sand particles of the mold. Also, the accuracy is not particularly high.

Die casting

Mold type: Metal

In this casting method, melted metal is injected into a metal mold under high pressure. Metal molds are expensive but can be used repeatedly, so this method is suitable for mass production. Surfaces of die cast parts are smooth, and highly accurate products can be manufactured quickly.

Permanent mold casting

Mold type: Metal

Melted metal is poured under only the force of gravity, without applying pressure. This method is called gravity casting or gravity die casting. Cast products using this method have high dimensional accuracy and excellent mechanical characteristics, so this method is suitable for parts that require high strength.

Lost-wax casting

Mold type: Plaster, ceramic

Melted wax is poured into a mold to make a wax model. The model is covered with plaster or ceramic. It is baked in a furnace to melt the wax. The wax melts and runs out, leaving a space in the baked plaster or ceramic which becomes the mold. Molds can only be used once but the cost to make them is low, so this method is suitable for small lot production. The surfaces of lost-wax cast parts are smooth, so highly accurate products can be manufactured.

Get detailed information on our products by downloading our catalog.

View Catalog

Types and Characteristics of Sand Casting

Advantages and disadvantages of sand casting

Advantages

- Wooden patterns require low initial investment.

- Wooden patterns can be produced quickly.

- Various shapes can be molded, which allows for casting of complex and large products.

- Suitable for small-volume manufacturing of many product types

- Any metal material can be cast. (Die casting can use only non-ferrous metals such as aluminum alloys, zinc alloys, and magnesium alloys.)

Disadvantages

- Low dimensional accuracy

- Casting surfaces are coarse due to the sand molds.

- Running costs are high because the sand molds are destroyed each time, so this method is not suitable for mass-production.

- Lower mechanical characteristics when compared to permanent mold casting due to low cooling speed

Types of sand molds

The various types of sand mold are differentiated by the bonding method employed. The two most common sand mold types are:

Green sand mold

Clay (bentonite) is added to silica sand and the binding strength of water is used to bond the sand mold. Silica sand is cheap because it is produced naturally, but it is not suitable for mass-production.

Shell mold

A sand-resin mixture produced by mixing thermosetting phenolic resin with silica sand is used. This type of mold is called a shell mold because the mold is thin like a shell.

Thin shell molds form smooth surfaces and are often used for precise casting of automotive engine parts and similar parts. Shell molds can be destroyed easily, which makes them suitable for mass-production. However, they are more expensive when compared to green sand molds because metal patterns must be used.

Sand particle size

The sand particle size greatly affects casting surfaces.

Smaller sand particles form smoother casting surfaces, but they hinder air flow and can confine gases which can result in defects. Larger sand particles form coarse casting surfaces, but they facilitate air flow and thus can produce castings with fewer defects caused by gases.

The sand particle size should be selected according to the needs of the application.

We’re here to provide you with more details.

Reach out today!

Typical Casting Defects

Typical casting defects include the following.

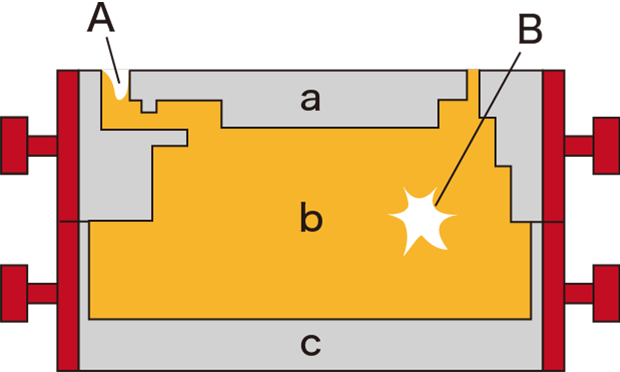

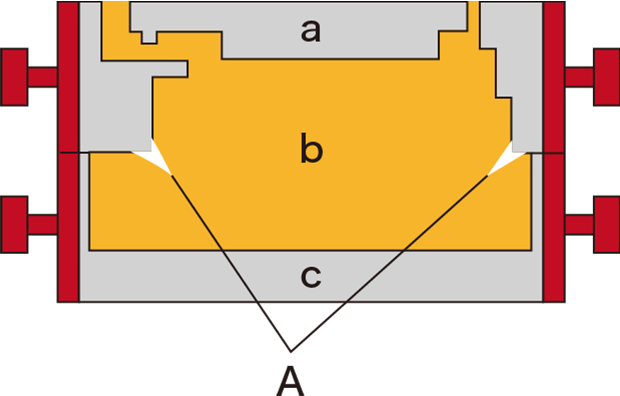

A: External shrinkage cavity B: Shrinkage cavity

a: Upper mold b: Core c: Lower mold

Shrinkage cavity

A shrinkage cavity is a type of cavity. Shrinkage cavities are relatively large complex-shaped hollows that occur inside of cast objects due to volumetric shrinkage when objects change from liquid to solid.

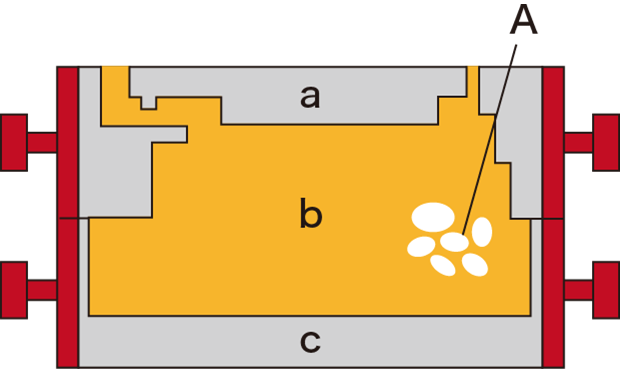

A: Blowholes

a: Upper mold b: Core c: Lower mold

Blowhole

Blowholes are another type of cavity. Blowholes are roundish hollows in cast objects. Melted metal includes air or other gases when it is poured into molds, which causes blowholes.

A: Cracks

a: Upper mold b: Core c: Lower mold

Crack

Cracks are fissures that occur on the surface of cast objects. Cracks occur due to the stresses that remain due to volumetric shrinkage or other causes during casting.

Misrun

A misrun occurs when a mold cavity fails to be filled all the way with molten metal, resulting in an incomplete cast product shape.

Burr

Burrs occur along matching surfaces (parting surfaces). Mold accuracy defects, incorrect assembly, and enlarged clearance due to deterioration are common causes of burrs.

Dimension defect

Molds are made with consideration to volumetric shrinkage or deformation during casting. Incorrect expectations, mold dimension defects, or incorrect assembly can cause this problem.

Casting surface defect

Casting surface defects occur when the sand of a mold surface melts and burns onto the cast product surface.

We’re here to provide you with more details.

Reach out today!

Examples of Observation and Analysis of Sand Casting Using a Digital Microscope

The latest examples of observation and analysis of sand casting using KEYENCE’s VHX Series 4K Digital Microscope are introduced below.

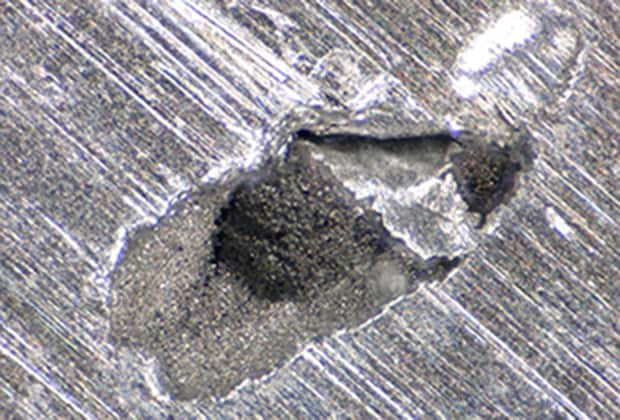

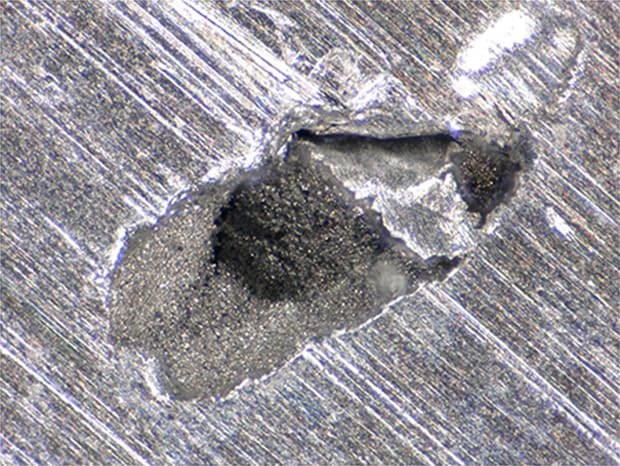

Depth composition image of a cavity

200×, ring illumination

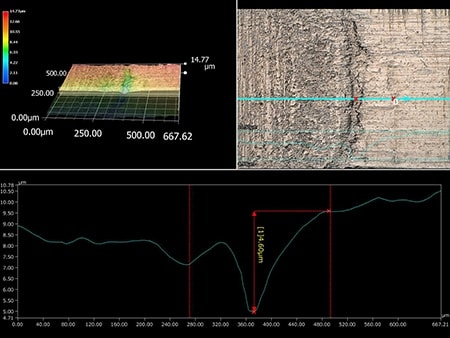

Profile measurement image of a cavity

200×, ring illumination

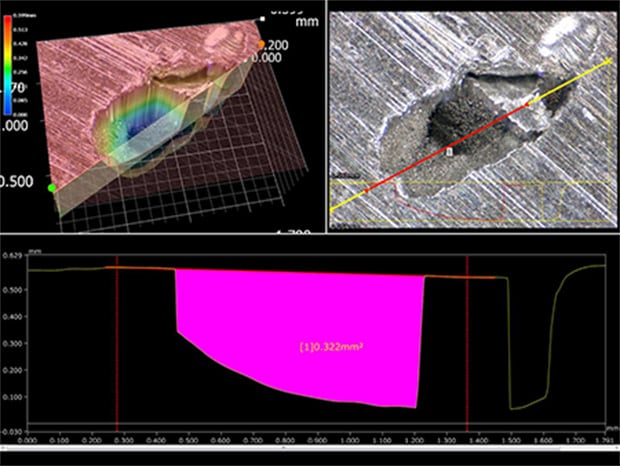

Depth composition image of a cavity

200×, ring illumination

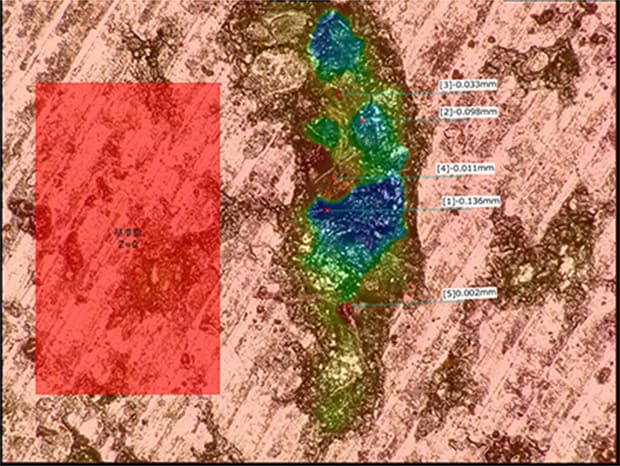

Point height measurement image of a cavity

200×, ring illumination

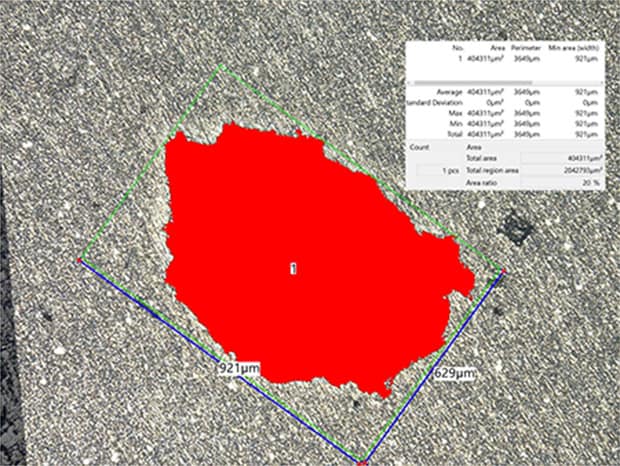

Maximum area measurement of a cavity

200×

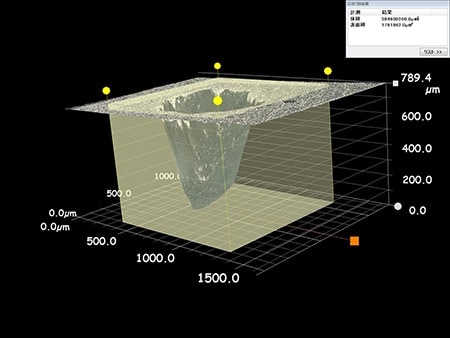

Volume measurement image of a cavity

200×

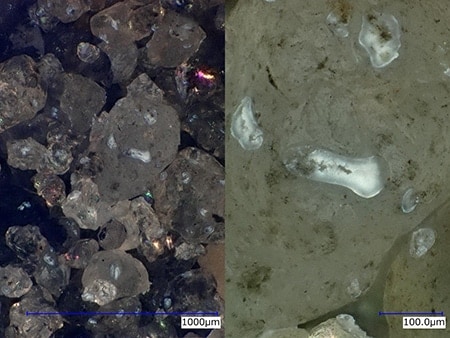

Observation of a sand mold surface

150×, ring illumination

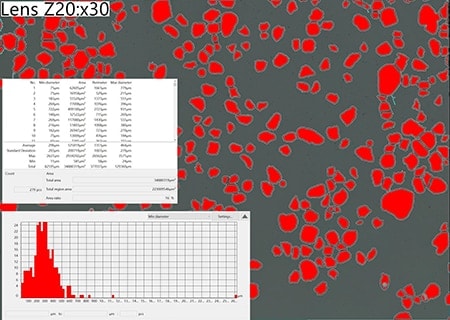

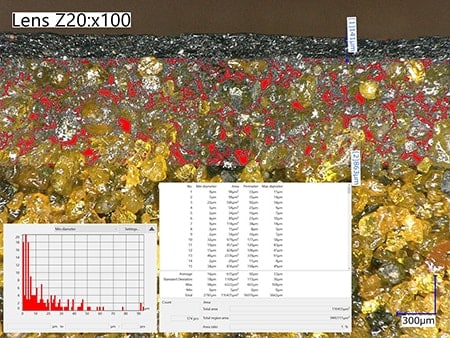

Sand particle size analysis

30×

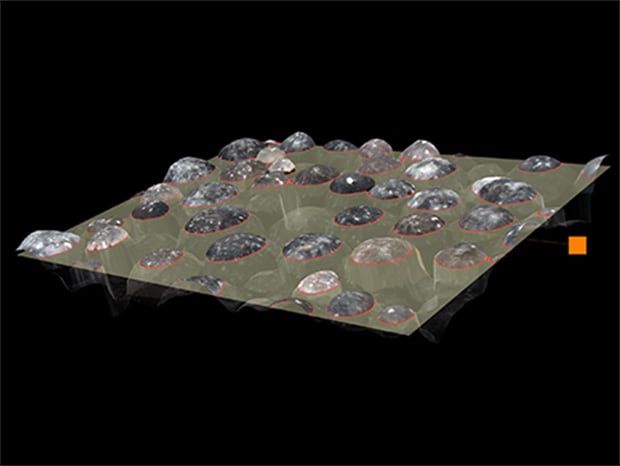

3D image of resin-coated sand

200×, ring illumination

Surface area measurement image of resin-coated sand

200×, ring illumination

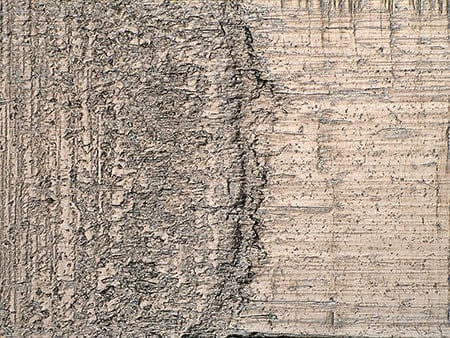

Observation of the state of sand adhesion

100×, ring illumination

Observation of the adhesion state of sand adhesive (binder resin)

500×, coaxial illumination

Depth composition image of a cast aluminum surface

20×, ring illumination

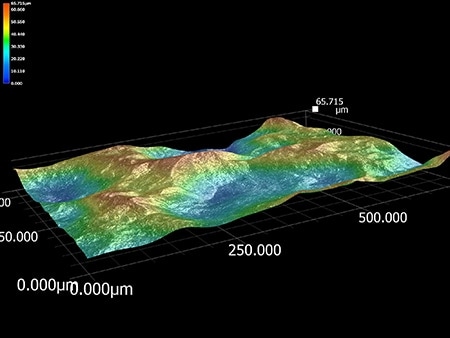

3D image of a cast aluminum surface

400×, ring illumination

Depth composition image of a cast surface

500×, coaxial illumination

3D measurement image of a cast surface

500×, coaxial illumination

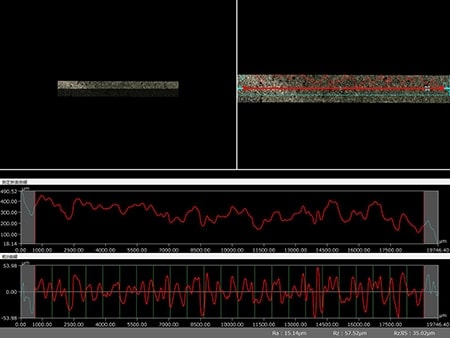

Surface roughness measurement of a casting core

100×, ring illumination

Get detailed information on our products by downloading our catalog.

View Catalog