Digital Microscopes

Observation, Analysis, and Inspection of Injection Molding Defects and Molding Materials

The injection molding of resin (plastic) materials is a delicate process, which can be subject to molding defects that impair quality depending on molding requirements and the conditions of materials and additives. Types of molding defects and how they occur can vary greatly.

This section explains typical molding defects and the causes of such defects. This section also introduces example applications of using KEYENCE’s latest 4K digital microscope, which achieves quick and accurate observation, measurement, and evaluation of such defects.

Needs and Defects of Plastic-Molded Products

Against the backdrop of the need for lighter weight materials, molded products using plastics with higher functionality and increased durability are being adopted in diverse fields. For example, in the automotive industry, it is possible to achieve energy savings by utilizing a lightweight design where some components, previously made of metal, have been replaced with high added-value injection-molded products.

On the other hand, with injection-molded products, various conditions—including the proportions and dispersion of material and additive contents, the temperature used to melt the plastic, the pressure, and the cooling time—significantly affect quality. Particularly in injection molding, a typical method of forming plastic, care must be taken with the mold and the melting plastic pressure. Furthermore, caution and preventive measures must be implemented to prevent mold release problems, which can cause system stoppages and damage to molds.

Get detailed information on our products by downloading our catalog.

View Catalog

Typical Molding Defects

Examples of typical molding defects (deformation and surface defects) that impair the quality of plastic-molded products and the factors that cause such defects are provided below.

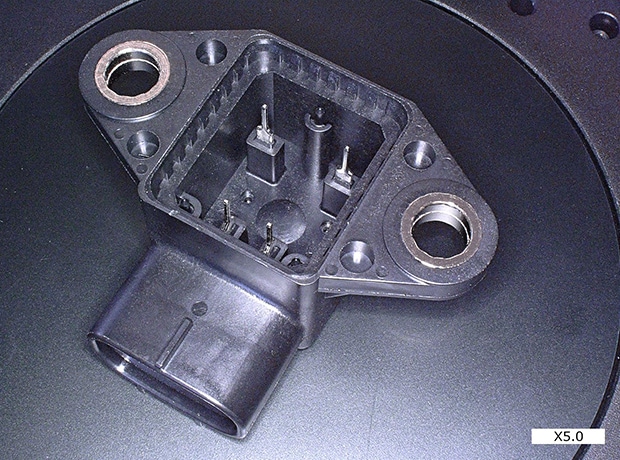

Flash

Phenomenon: Deformation that involves melted plastic solidifying outside and along the parting line of the two halves of the mold.

Possible causes: High injection output, insufficient mold clamping, excessive amount of plastic being injected, distortion in mold, etc.

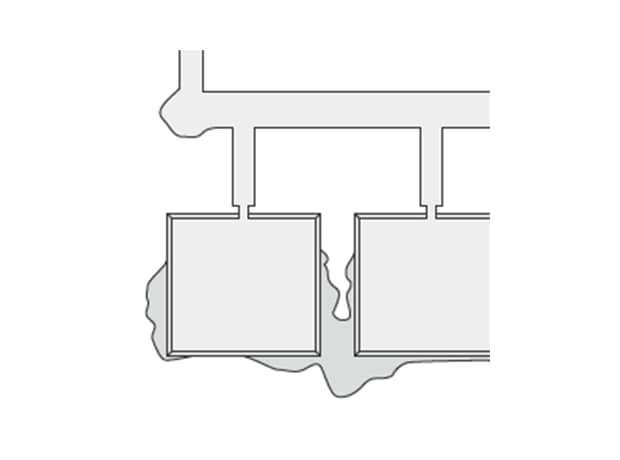

Sinkage

Phenomenon: Deformation that is a dent in the surface of a molded product. It is also called a sink mark.

Possible causes: The shrinkage that occurs while the melted plastic solidifies inside the mold causes an insufficiency of plastic volume to fill the mold, resulting in a dent. When sinkage occurs inside the molded plastic, it is called a void.

Warpage

Phenomenon: Deformation in which the molded product warps in one direction.

Possible causes: Deformation caused by external force during mold release (mold release failure) or different shrinkage rate due to the direction of melted plastic flow inside the mold.

Weld Line

Phenomenon: Surface defect in which the weld, or the part where the flows of melted plastic meet inside the mold, shows up on the surface as a groove or pattern.

Possible causes: Low temperature or fluidity of melted plastic during injection molding. Insufficient injection pressure and speed can cause weld lines.

Flow Line

Phenomenon: Surface defect in which wavy streaks form like a ripple centered around the gate.

Possible causes: Low temperature of injected melted plastic or slow injection speed during injection molding resulting in low fluidity of plastic inside the mold. The streaks form from plastic in the mold overlapping with plastic following it.

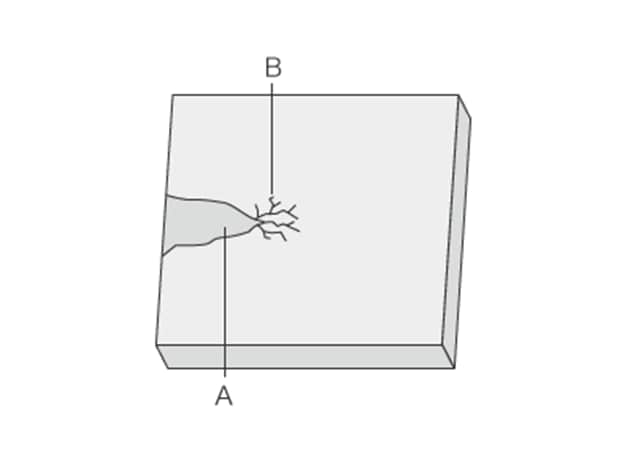

A.Crack B.Crazing

Cracking and Crazing

Phenomenon: Surface defect where cracks and crazing (fine cracks and lines) occur.

Possible causes: Cracks and fractures may occur in molded products due to external or internal stress.

We’re here to provide you with more details.

Reach out today!

Latest Examples of Observation and Inspection of Plastic-Molded Products, Materials, and Additives

The aforementioned molding defects, bubbles entering the plastic materials, and dispersion of filler and other additives all significantly affect quality. Furthermore, plastic-molded products in general are subject to frequent observation and evaluation using optical microscopes.

However, conventional optical microscopes do not support accurate appearance inspection by observation for molded products that have attributes such as low color contrast, three-dimensional shapes, complex-shaped zones, surface gloss, and transparency. They also did not allow for quantitative evaluation by measurement of defective portions or dispersion of material particles and additives.

Developed based on the input and feedback from actual users we have received over the years, KEYENCE’s VHX Series high-definition 4K Digital Microscope solves all the issues with conventional optical microscopes. One unit can also accommodate new needs in the R&D and manufacturing of recent sophisticated injection-molded products, materials, and additives.

The VHX Series is equipped with a high-resolution lens and 4K CMOS, which enables accurate observation, quantitative 2D and 3D evaluation, and automatic report creation.

This section introduces examples of the application of the VHX series in evaluating injection-molded products, materials, and additives.

Observation of weld lines

With the exception of multi-colored molding, injection-molded products are generally single-colored and therefore have low contrast, which does not cater to easy observation of surface defects. It was particularly difficult to identify suitable lighting conditions for the observation of weld lines, which are grooves or patterns caused by poor fusion in the weld, where flows of melted plastic meet in the injection mold.

The multi-lighting function of the VHX Series 4K Digital Microscope can quickly obtain multiple images with lighting from all directions at the push of a button. Observation can be performed by simply selecting images suitable for observation from the collection of images.

Users can experience quick and accurate observation, saving time previously spent on figuring out suitable lighting conditions.

Observation of Weld Lines Using the VHX Series 4K Digital Microscope

Normal (100x)

Multi-Lighting (100x)

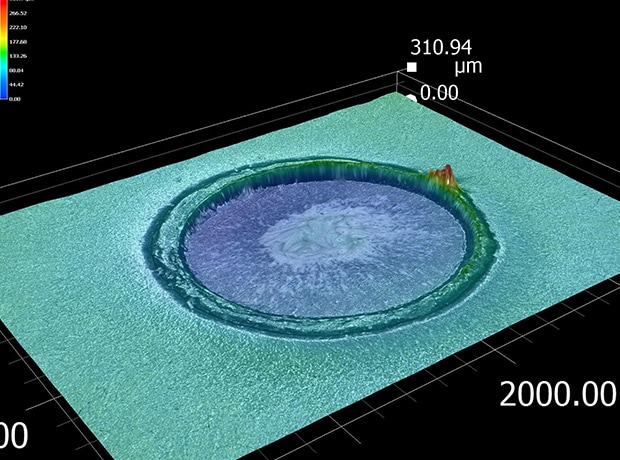

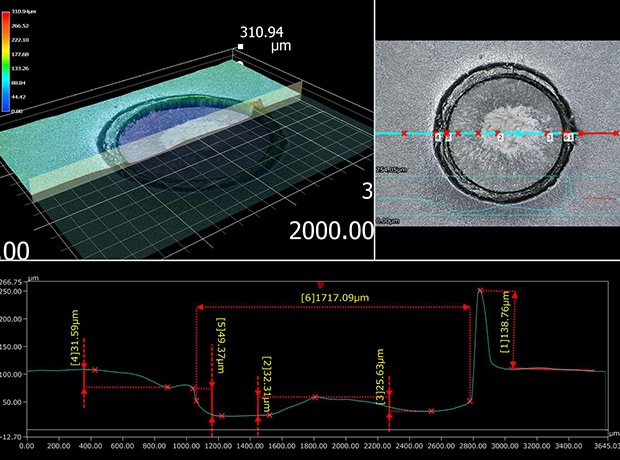

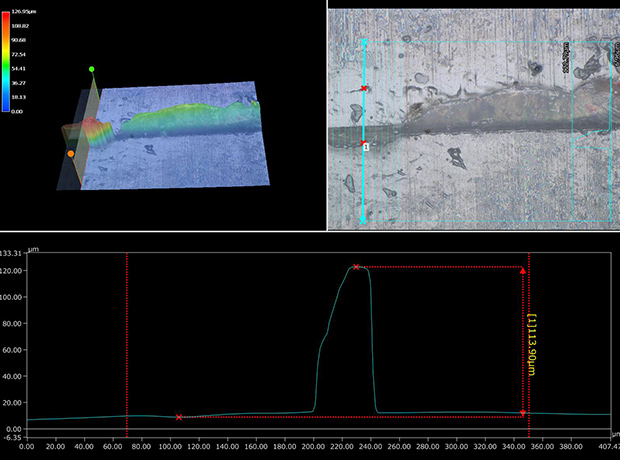

3D measurement of flash in molded products

The VHX Series 4K Digital Microscope can measure highly accurate 3D shapes on the submicron order and profiles of defective parts, all in addition to observation using high-definition images.

KEYENCE’s 4K digital microscope can perform quantitative measurements and inspections on even microscopic flash that occurs when some melted plastic escapes from the slight gap in the parting line due to distortion in the mold or insufficient clamping force. The acquisition of detailed three-dimensional information of the defective part can also contribute to swift detection of the cause, from which preventive measures can be sought.

3D Measurement and Profile Measurement of Molding Flash Using the VHX Series 4K Digital Microscope

3D measurement and 3D shape display of flash (100x)

Profile measurement of flash (100x)

Profile measurement of microscopic flash in parting line (500x)

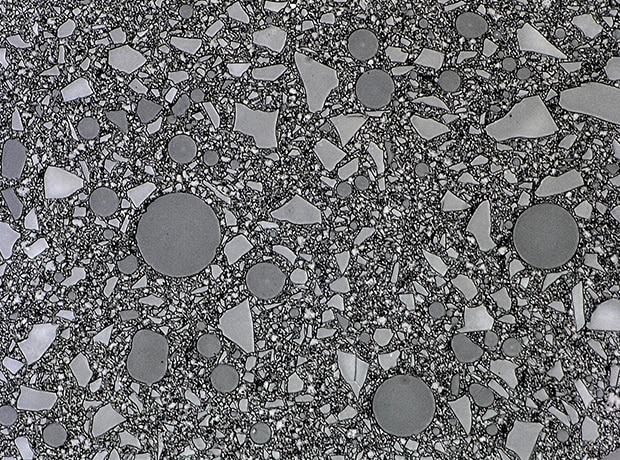

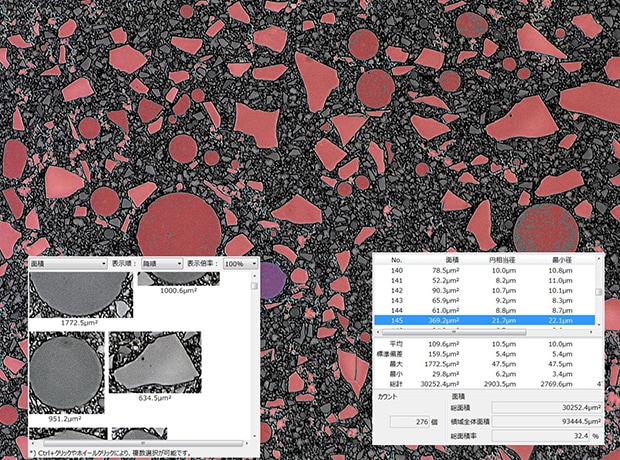

Observation and automatic measurement of filler dispersion in plastic

Filler and additives are used to increase functionality and add more value to the resulting plastic products. Uniform dispersion of filler and other additives in the plastic material is a challenge in plastic injection molding. Therefore, accurate evaluation by means of observation and measurement of filler dispersion is important.

The VHX Series 4K Digital Microscope allows for observation of filler dispersion using high-definition 4K images even at high magnifications. The observation images can also be used for highly accurate automatic area measurement and counting, thereby enabling seamless quantitative evaluation based on both observation and measurement.

By using templates, operators can also use the VHX Series to automatically create reports using captured images and measured values. With a single microscope completing a series of tasks, the efficiency of the evaluation of filler dispersion is significantly improved.

Observation and Measurement of Filler Dispersion Using the VHX Series 4K Digital Microscope

Observation of filler dispersion (1000x)

Automatic area measurement of filler dispersion (1000x)

Observation of plastic material particles

Due to the uneven surface of plastic materials, conventional microscopes can only partially focus on the full field of view when observing the particles of plastic materials. Additionally, the ring-like reflected light caused by the gloss of the material has made observation of bubbles difficult.

The real-time depth composition function of the VHX Series 4K Digital Microscope makes it possible to obtain fully-focused images even when the target has an uneven surface. The ring-reflection removal function can also be applied to remove the ring-like reflected light for a clearer observation of plastic material particles and bubbles.

Observation of Plastic Particles Using the VHX Series 4K Digital Microscope

Normal (200x)

Depth composition + ring-reflection removal (200x)

Observation of a fractured surface on an injection-molded product

Causes of breakage and fractures in plastic-molded products can be identified by quickly and accurately analyzing the state of the fractured surface (brittleness, ductility, shear, fatigue, creep, etc.), which contributes to early undertaking of preventive measures and improvements.

The high-resolution lenses and motorized revolver of the VHX Series 4K Digital Microscope enable a seamless zoom function that automatically switches between lenses from 20x to 6000x magnification with intuitive operations. This saves the time and effort, otherwise spent on lens exchange, to capture a high-definition 4K image, thereby achieving accurate and efficient observation and analysis of the fractured surface.

Observation of a Fractured Surface on a Molded Product Using the VHX Series 4K Digital Microscope

Observation of a fractured surface of a molded product (20x)

Observation of a fractured surface of a molded product (50x)

Free-angle observation system and high-accuracy XYZ motorized stage

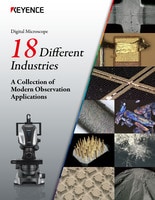

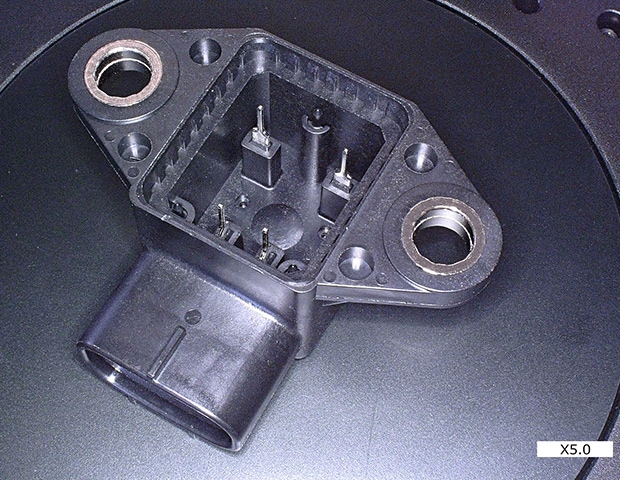

Tilted observation and appearance inspection of composite molded products

An appearance inspection of a composite molded product with a complex, three-dimensional shape, such as a connector for vehicle electrical parts, requires observation from multiple different angles.

Using the free-angle observation system and the high-accuracy XYZ motorized stage of the VHX Series 4K Digital Microscope enables tilted observation from a wide variety of angles. Smooth tilted observation is possible with no need to manually adjust the workpiece position.

Low-Magnification, Tilted Observation of Composite Molded Product (5x)

Appearance Inspection of Molded Product Using the VHX Series 4K Digital Microscope

The high-resolution, high-definition 4K images created by the VHX Series’ high-resolution lens and 4K CMOS can clearly capture sink marks, flow lines, and other fine defects in molded products even for low-magnification observation capturing the target in full.

We’re here to provide you with more details.

Reach out today!

A User-Friendly, Multi-Function, High-Definition Microscope Reflecting the Needs of Users

KEYENCE has continuously improved and reformed its digital microscopes for over 20 years by reflecting the feedback and input provided to us by on-site customers. The fruit of such efforts is the VHX Series high-definition 4K digital microscope.

In addition to the functions introduced here, the VHX Series is equipped with many more useful functions that can offer solutions to problems experienced on site. All functions are uniquely designed to offer a system that enables advanced observation and inspections with simple operations regardless of the skill level of the operator.

The wide variety of lens types and observation systems also supports a customized setup for the targets and materials you are handling.

For details on the VHX Series, click the button shown below to download the brochure. For inquiries, click the other button shown below to contact KEYENCE.

Get detailed information on our products by downloading our catalog.

View Catalog