Digital Microscopes

Observation and Measurement of Pigments Using Digital Microscopes

Colorants, which are used to color artificial materials we encounter every day, are roughly classified into two types: pigments and dyes. Colorants that are insoluble in solvents are called pigments and those that are soluble in solvents are called dyes. Usually, dyes are used to color fibers and pigments are used to color paints and cosmetics. This section introduces examples of observation and measurement of pigments using digital microscopes.

Differences between Pigments and Dyes

Pigments and dyes are both colorants, but their uses differ due to their different properties.

Pigments remain on an object surface to color it.

Pigment

Pigments are colorants that are insoluble in solvents, such as water and oil, and remain on object surfaces. They are classified into two types by their materials: inorganic pigments and organic pigments.

Inorganic pigments are weather resistant and cheap, so they are often used for paints applied to products that have large application areas and are left outdoors for long periods.

Organic pigments have vivid colors and are commonly used to color print inks and plastic products.

Dyes soak into an object to color it.

Dye

Dyes are soluble in water and oil and can soak into the fibers of materials such as fabrics and paper. New colors can be created easily by mixing multiple colors, but dyes have the disadvantage that they easy fade when exposed to light for a long time.

Get detailed information on our products by downloading our catalog.

View Catalog

Pigment Types

Some pigments have functions for specific purposes. This section introduces typical pigment types and their uses.

- Color pigment

This type of pigment is mixed to color objects. Inorganic pigments are used for muted colors, such as black and white, and organic pigments are used for vivid colors, such as yellow, green, and red. - Anti-corrosion pigment

This type of pigment has anti-corrosion functions. Anti-corrosion pigments are mixed into metal coating agents and form a coating to prevent rust and corrosion. - Extender pigment

This type of pigment is mixed into coating agents, inks, paints, cosmetics, and similar products as an extender or to add properties such as fluidity, strength, gloss, viscosity, and adhesive properties. - Functional pigment

Functional pigments add capabilities other than coloring. These include fluorescent pigments that create fluorescent colors, luminous pigments that glow at night, titanium oxide that adds photocatalytic functions, magnetic iron oxide that adds magnetic properties, cuprous oxide that helps protect from dirt, and aluminum powders and glass beads that create color tones such as metallic, pearl, and gold colors.

We’re here to provide you with more details.

Reach out today!

Pigment Observation and Measurement Examples Using Digital Microscopes

These are the latest examples of observation and measurement of pigments using KEYENCE’s VHX Series 4K Digital Microscope.

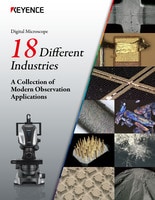

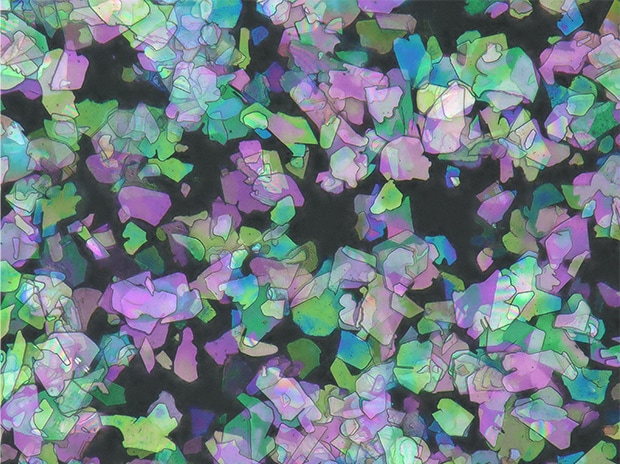

Observation of a pigment (mica) surface

VHX-E500, 1000×, coaxial illumination

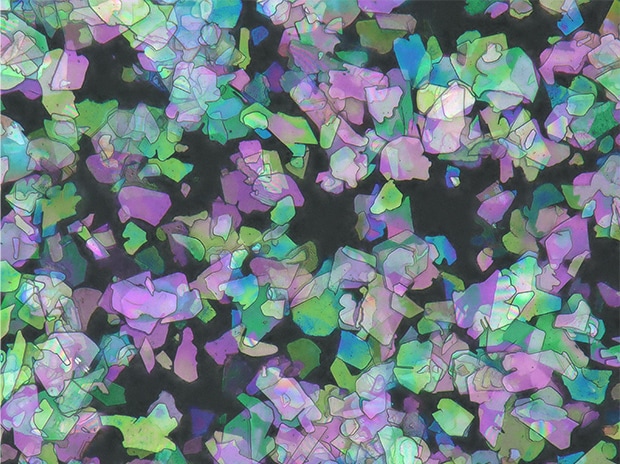

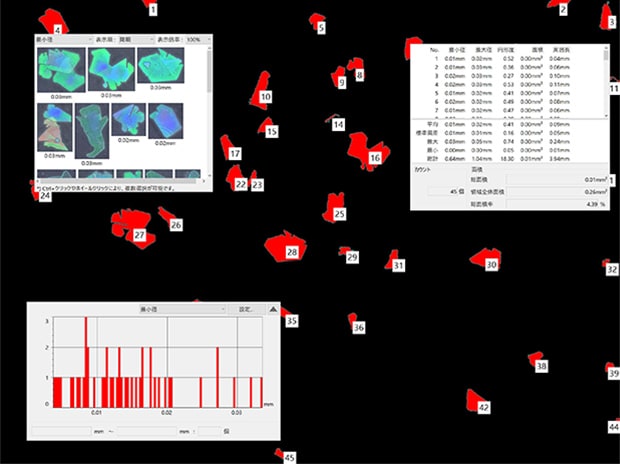

Automatic area measurement of a cosmetic pigment

VHX-E500, 500×, mixed illumination

The automatic area measurement function automates measurement and report creation which used to be performed manually.

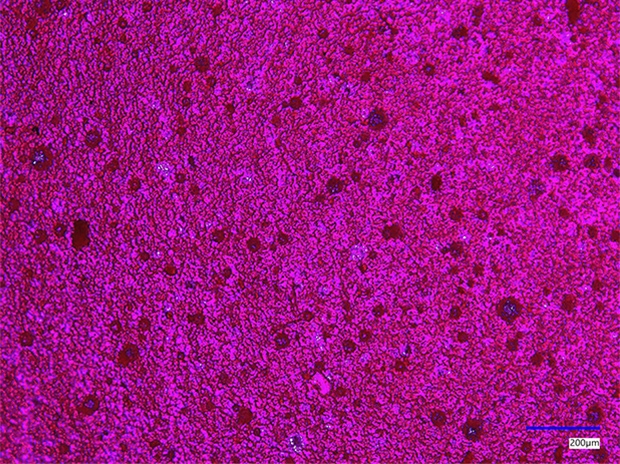

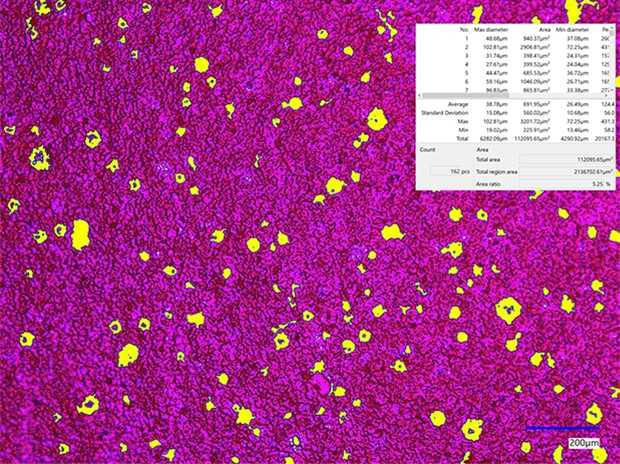

Observation of a pigment (mica) surface

Evaluation of clumpy particles allows for OK/NG judgment of pigments.

VH-Z100, 200×, coaxial illumination

Before measurement

VH-Z100, 200×, coaxial illumination

Automatic area measurement image

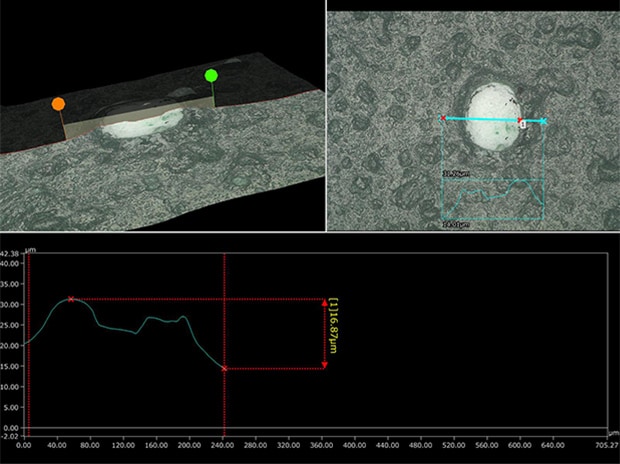

Color failure analysis of a pigment

Using the 3D measurement function eliminates the need to cut products to analyze cross-sections.

ZS-200, 500×, coaxial illumination

Get detailed information on our products by downloading our catalog.

View Catalog